Keep Your Parts in Place and Increase Efficiency and Output

Innovative fixturing systems and welding tables ensure you achieve consistent results and better part quality.

Posted: January 18, 2023

Reduce setup times and secure your parts with robotic positioners, modular workholding solutions or customizable weld stations for increased accuracy through the flexibility provided by these systems.

Validation Center Delivers Proof of Concept

Bluco® Corp. (Naperville, IL), designers and manufacturers of modular workholding systems, offers customers a unique space to test and perfect modular solutions offline, without putting production at risk.

Collaboration Sets the Stage for Success

The concepting of workholding solutions for welding, machining, robotics and positioning applications begins with in-person and virtual sessions hosted by an experienced Bluco application engineer. Once the design is 99% dialed in, it’s time for a vetting process that ensures the modular solution meets or exceeds expectations.

Validation Begins with Testing, Perfecting

The proving process takes place inside Bluco’s Validation Center, a 7,000-square-foot industrial space containing all the technology and equipment needed to weld a part from start to finish.

The customer brings their welders and raw materials, and working alongside Bluco engineers, they go through the same process they’d use in production at their own facilities.

If adjustments are needed, they can be made instantly. Bluco’s extensive on-site inventory allows parts to be swapped out in minutes.

Implementation Made Seamless

Once the solution is proven out, Bluco can install it on-site and provide training to get the system up and running quickly. The result is a modular solution that delivers consistent results — without unwanted risk.

Evaluation Reveals Results

The results delivered by Bluco’s collaborative working model and hands-on validation process can be found in case studies and testimonials on Bluco’s website. Among them are manufacturers who’ve cut production times in half, increased accuracy exponentially, achieved better final part quality, and significantly reduced manufacturing costs.

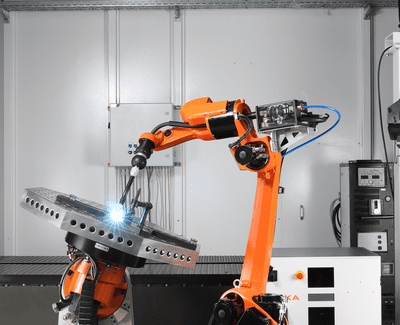

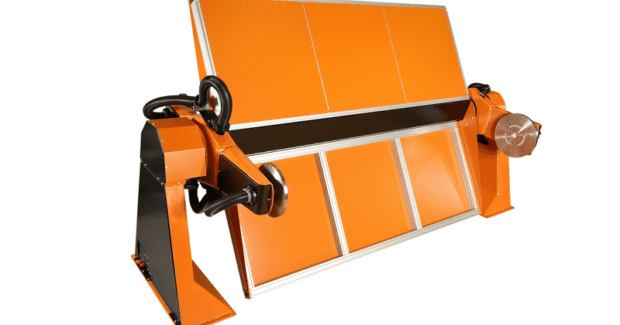

Robotic Positioners that Enhance Performance and Automation

KUKA’s DKP 400.

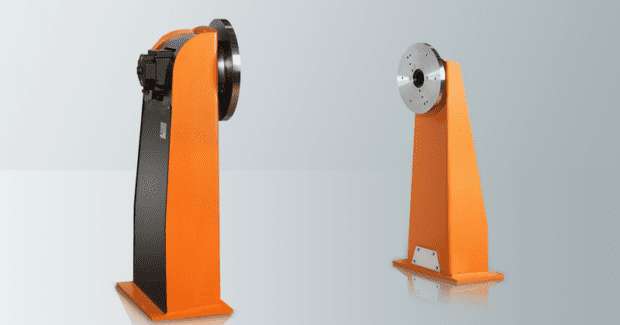

KUKA’s KP1-HC.

KUKA (Shelby Township, MI) offers a broad line of robotic positioners to increase efficiency and output. For accuracy and production quality, KUKA’s positioners employ proven robotic components for high availability and reliability as well as maximum torque for extremely short cycle times.

KUKA’s KP1-HC single-axis positioner with horizontal rotational axis consists of a drive and counterbearing with a hollow shaft. It is available with a payload capacity of 500, 750, 1,000, 1,500, 2,000 or 4,000 kg. Tool radii of 800-to-1,470 mm offer maximum possible flexibility in system design. Its compact design allows the KP1-HC to be easily integrated anywhere, and infinite rotating design enables it to be used without limitation in any axis orientation.

Another positioner is the KP3-V2H 3-axis positioner with two machining stations, which offers maximum flexibility in terms of payload capacity, tool radii and distances between face plates and is available with a payload capacity of 500, 750, 1,000 or 1,500 kg. Face plates on the KP3-V2H are electrically insulated, which simplifies the integration process and improves the longevity of the positioner, particularly in arc welding applications.

With a payload capacity of 400 kg, KUKA’s DKP 400 2-axis positioner with one rotational and one tilting axis enables the flexible machining of workpieces. Regardless of the axis it’s using, the DKP’s tilt-turn positioner finds the required position quickly and precisely with the capability to allow a supply of energy and fluids through the face plate.

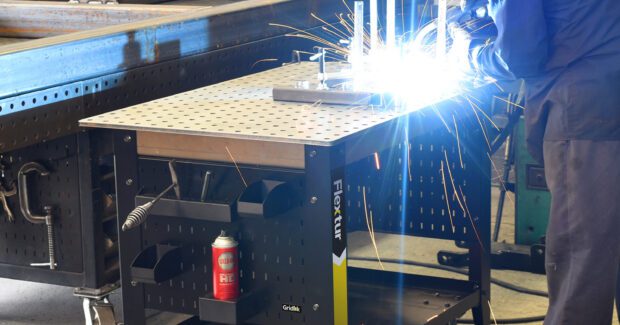

Mobile Welding Cart Ready to Deliver for Years to Come

Flextur’s (Dalton, OH) new made in the USA Mobile Welding Cart featuring Gridlok can support and transport 1,750 pounds. This Mobile Welding Cart is ideal for cobots, or any on-the-go welding workcell. The 14-gauge Gridlok can support 50 pounds on a single hook, which provides superior flexibility and strength when organizing tools and materials within easy reach.

Other features include a 30” deep-x- 48” wide-x-35” high work surface; a 1/2” top with 1/4”-x-4” gussets for accuracy and rigidity; and 16 mm holes on 2” grid spacing, among others.

A full bottom shelf provides ample space for a welder or cobot controller. This robust and highly mobile solution is Flextur’s agile response to the industry’s needs.

Subscribe to learn the latest in manufacturing.