OMAX: Waterjets are in Its DNA

With a sole focus on building abrasive waterjet machinery, the newest generation of OMAX brand core products is the culmination of nearly 30 years of work.

Posted: December 22, 2022

SUPPLIER PROFILE

The OMAX brand from Hypertherm Associates was founded by engineers in Kent, Wash., in 1993 with a goal of continuous focus on research and development and bringing to market abrasive waterjet machining that is more precise, affordable and easy to use. Even when encountered with challenges in the market — for instance with COVID 19 — the brand has never wavered from a constant R&D focus on waterjet technology. By not diverting from that course, waterjets are truly in the OMAX DNA.

The current economy is challenging, to say the least. Regardless of what the economy is doing, Hypertherm Associates continues to invest and develop new OMAX waterjet functionality. Hypertherm Associates (Hanover, N.H.), supports the OMAX brand’s commitment to R&D. “The Hypertherm and OMAX brands have a very similar background,” said Steve Ulmer, director of sales for OMAX brand products. “The brands were both founded by engineers as well and use that as the foundation of how they support end users.” The Hypertherm Associates family is a 100% employee-owned company composed of industrial cutting technologies and solutions including plasma, waterjet, software and more.

Abrasive waterjets can cut virtually any material in a range of material thicknesses. According to the OMAX brand website, waterjet cutting technology consists of a high-pressure pump, a cutting table that holds the work material, a nozzle that emits the jet stream, an X-Y motion system to move the nozzle and a PC-based controller.

Tables are water-filled tanks with slats that hold the material, which can be submerged under the water, making the cutting quiet and clean. Hoppers hold and dispense abrasive during the cutting process. This cold cutting process does not create heat-affected zones, which means it doesn’t change the material properties or leave heat-hardened edges.

“One thing that sets us apart is all of our OMAX waterjet products are designed, built and shipped from here at the factory in Kent,” Ulmer said. The brand’s 300,000-plus-square-foot campus is comprised of four buildings where the machines are tested as components and built as a system before being shipped from the factory. “That is unique in the field,” Ulmer said. “Most everyone else in the waterjet field is shipping from different locations and they [machines] don’t finally meet up until the customer’s floor.” When it comes to support, customers call only one number with questions on any aspect of the machines, be it pumps, software and so on.

The ability to operate from one location provides the OMAX brand with a few more options during times of challenge, for example with supply chain constraints. In many cases, OMAX just sources material such as stainless steel, mild steel and aluminum, and does not source parts. Another advantage is that as part of Hypertherm Associates, the brand benefits from the purchasing power of Hypertherm Associates to assist during pain points.

“It was really well timed when we were acquired by Hypertherm Associates,” Ulmer said. “Their purchasing team came in and helped our purchasing team shortly after COVID-19 hit and the supply chain started to have some issues. Having a bigger footprint was without a doubt a benefit to us and beneficial to our customers.”

Top Solutions

OMAX products are used by companies around the world to build ships, airplanes, and railcars, construct steel buildings, fabricate heavy equipment and more.

Ulmer said the focus for the engineering staff of OMAX brand products is on how to make the machine tool more user friendly. “I think the OMAX OptiMAX is the indication of where we want to go,” he said. “The feedback we have gotten from the field is that labor continues to be problematic for our end users in terms of finding labor and maximizing what they do get from that labor. So, with the OptiMAX being able to fix and correct itself as its running without the operator intervening — it gives a good indication of where we are going in the future.”

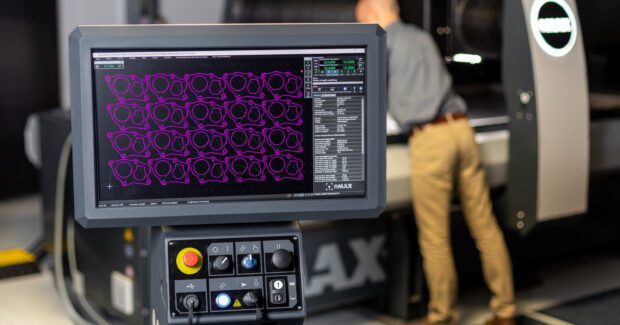

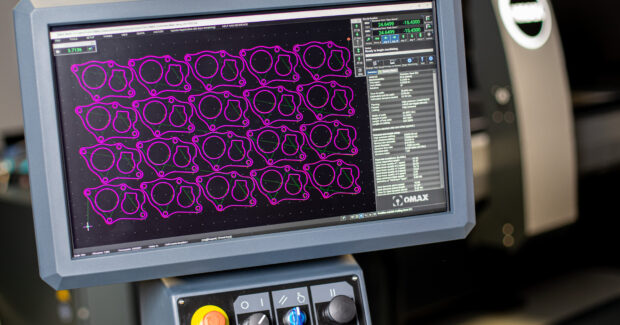

In the OMAX OptiMAX, Hypertherm Associates offers the most advanced waterjet ever. This new generation of waterjet was released in March 2022 and is designed for quickly turning prints into parts with reduced dependency on highly experienced operators. The machine is the result of three decades of expertise and user experience.

“The key things that it brings to the end user is a smart and connected machine that has all of the data and all of the inputs from what the machine is doing readily available at the workstation; and it is also accessible to the production manager or the owner of the company,” Ulmer said.

By accessing the information in real time, operators can track the functions of the machine, from the pump to the cutting head and so on. Ulmer said that a powerful aspect in addition to the real time data, is that the OptiMAX is also connected in such a way that one operator can operate several machines. End users have always been able to operate multiple machines, but the OptiMAX machines take things to the next level with fault detection and correction.

“For example, if there is a hiccup in the abrasive feed system, it has the ability to fix the problem in the abrasive feed and get back to cutting without the operator having to stop and pause and clean anything out,” Ulmer noted. “The machine will do it for the operator.”

The OptiMAX includes IntelliMAX software, which features decades of proprietary waterjet cutting models, designed for ease of use and operation. The IntelliVISOR console helps avoid unplanned downtime; and the IntelliTRAX drive system with motion control increases reliability with virtually no maintenance required when compared to conventional ball screw and rack and pinon drive systems.

Finally, the EnduroMAX pump automatically sets the correct pressure and minimizes fluctuations to improve component life and achieve faster cutting times. The direct drive waterjet pump technology offers 1,000 hours between maintenance services. Direct drive pumps don’t require hydraulic oil, eliminating the need for chemical disposal when conducting maintenance. Also, the water and power consumption are significantly less than other types of waterjet pumps.

Hypertherm Associates offers two lines of the OMAX OptiMAX, the 60X and the 80X, and soon will roll out additional sizes in this series.

Another core OMAX brand machine series is the ProtoMAX, which is a machine with a smaller footprint, making it accessible to a wider range of end users thanks to its 1”-x-1” cutting envelop. The price point makes the machine a great entry into waterjet cutting. It runs on a 240-volt single phase power source, which supports usage in various locations including home garages.

Ulmer said the OMAX brand team has been taken by surprise regarding the interest in the ProtoMAX by Fortune 100 companies, which are using the machine for testing and R&D. This machine is being used by customers in metal service centers, the aerospace industry, testing labs, and by hobbyists making things for their own use or their small businesses. Ulmer said the machine is a proper machine tool and even though the size and footprint is small, the machine is ruggedly built to run and cut parts. “It is absolutely not a toy; it plays itself out every day in the field,” Ulmer said. “Everything we do here has the OMAX DNA built into it.”

First-hand Feedback

Customer feedback is one of the best indicators of how well OMAX machines perform in the field. For Simon Arthur, founder of Big Blue Saw, a 6,000-square-foot job shop in Atlanta, Ga., a love of robot wars (custom-built machines built to fight each other, think “BattleBots”) led him to seek out the tools and techniques needed to make the robots. He needed to look beyond the tools of his home garage to create advanced units with features such as articulating arms and motor-driven saws.

After disappointing results working with fabricators in his area where quality was oftentimes an issue, and because Arthur’s orders were for a small number of parts — if shops would even take his jobs — he opened his own shop in 2005. The focus is on low-volume parts production, and Arthur turned to internet commerce to grow his business, providing customers the ability to order custom, high-quality parts.

“I wanted it to be as easy to order one simple part as it was to order a thousand complex ones,” Arthur said. “My eventual goal was, and still is, to allow engineers, hobbyists, artists, crafters, designers, and makers of all kinds, the opportunity to turn a concept or idea into a real thing.”

From his early days as a robotic competitor, Arthur took notice of waterjet technology. As he began to use the technology himself, he appreciated the flexibility and utility of waterjets. What’s more, the waterjet could cut a variety of materials and thicknesses without creating a heat-affected zone on metal or chemically changing it.

When Arthur was looking to update his waterjet capabilities, his research led him to the OMAX brand, based on the ease of use and customer support. He selected the OMAX MAXIEM 1530 Jet-Machining Center, which can cut materials at a maximum speed of 500 inches per minute. The X-Y cutting envelop is 10’-x-5’, which accommodates standard plate sizes. “It’s been a very reliable machine and a pleasure to work with,” Arthur said. “It’s easy to train new operators on. It’s easy to process materials since the bed can accommodate 4’-x-8’ plates, with room left over. There is an ease of use with the software, and adjustments can be made on the fly.”

Hypertherm Associates is also playing a role in training the next generation of metalworkers. A capital grant awarded to the Science Leadership Academy (SLA) at City Center in Philadelphia, Pa., enabled the high school to purchase an OMAX abrasive waterjet cutting machine in order to fabricate complex parts in steel, such as a protective plate for a robot. With their own machine on site students no longer needed to outsource projects to a machine shop.

The SLA purchased the ProtoMAX, the compact, self-contained system with the 1’-x-1’ cutting envelop. The machine’s size, 39.5”-x-56.6”-x-41.5”, allowed the school to place the waterjet in the classroom as opposed to the shop. After about a month of retrofits to the school’s power and plumbing infrastructure, and about a day to install the waterjet, the SLA was up and running. In fact, 90% of what the students need to cut for their projects can be cut on the ProtoMAX’s cutting envelop.

A recent project was done in partnership with Philadelphia-based Tiny WPA, which is named after Franklin D. Roosevelt’s Work Progress Administration and supports community design improvement projects. The project involved waterjetting frames for four reproduced prints by printmaker Dox Thrash. One option for creating the frames was to cut steel parts and weld them together, which would be too time consuming. Tiny WPA reached out to the SLA.

“Each frame took about 45 minutes to an hour to cut,” said John Kamal, an engineering teacher at the school, noting that all the needed frames were cut in two days. With its 30,000-psi, direct-drive, 5-hp pump, “it’s not a fast machine,” he said.

Like Big Blue Saw’s Arthur, Kamal appreciated that the waterjet doesn’t create a heat-affected zone on the workpiece material, which is beneficial when producing a robotic gusset plate, as an example. “The last thing I want to do is have a bearing hole with additional hardness or less tensile strength,” Kamal said. A bonus is that the waterjet can cut more materials than the shop’s laser or CNC mills and lathes.

Bright Future

The leadership of Hypertherm Associates is positioned for whatever the future may bring. Ulmer said one issue on everyone’s mind right now is if 2023 will bring a recession. “I don’t think that question will be answered until we are in it,” he said. “But right now, things are looking positive. We are going into 2023 with a positive outlook on how businesses are running. We are moving forward as fast as we can and trying to answer customer concerns as fast as we can.”

Ulmer noted that exhibiting at recent trade shows, FABTECH and IMTS, were positive experiences for Hypertherm Associates. “It was a really good showing in both places,” Ulmer stated. “Waterjet is still a relatively new technology and if a customer is looking for a waterjet, I think you need to look at a company that is putting out new things and looking to the future and putting money into R&D, so they are developing the machine for today, and 10 years down the road.”

Ulmer also pointed out that end users should research waterjets that have the software and an operating system that will continue to ensure productivity and competitiveness years down the road as well. He noted that as part of Hypertherm Associates, customers of OMAX brand systems benefit from the experiences of two successful brands. Although they offer different cutting technologies (Hypertherm is a plasma cutting brand) the brands are complementary and supportive of each other. “It is a mutually beneficial relationship for both of us,” Ulmer said. “It is starting to pan out to be beneficial to us and the customers.”

“We are going into 2023 with a positive outlook on how businesses are running. We are moving forward as fast as we can and trying to answer customer concerns as fast as we can.” — Steve Ulmer, director of sales, OMAX brand.

“One thing that sets us apart is all of our products are designed, built and shaped from here at the factory at Kent. That is unique in the field.” — Steve Ulmer, director of sales, OMAX brand.

Subscribe to learn the latest in manufacturing.