#HandsOnMetrologyFair Organized by Exact Metrology

The fair featured discussions, presentations and demonstrations on several 3D scanning solutions available in the GOM #HandsOnMetrology tool kit.

Posted: December 29, 2022

Exact Metrology: A Division of In-Place Machining Company, a comprehensive 3D metrology service provider and hardware sales company, hosted their #HandsOnMetrologyFair in Brookfield, Wisconsin, Cincinnati, Ohio and Moline, Illinois. The fair featured discussions, presentations and demonstrations on several 3D scanning solutions available in the GOM #HandsOnMetrology tool kit including ATOS Q, T-SCAN hawk and Scan 1.

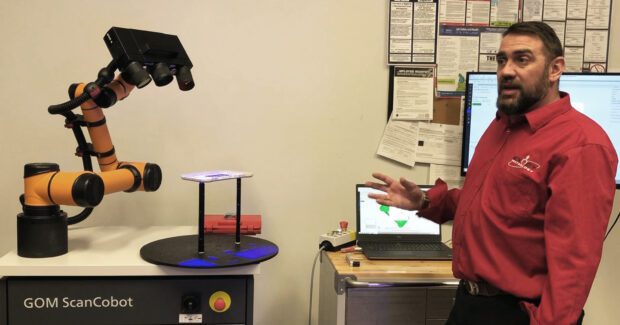

One of the demonstrations involved a GOM ATOS Q structured light scanner on a cobot mounted to a portable cart that can be taken wherever it’s needed. ATOS Q is a flexible 3D scanner for complex measurement and inspection tasks in different industries. The scanner delivers fully traceable measurement results, especially in harsh conditions. It captures quality information quickly and with a high degree of detail, providing a reliable basis to easily interpret the information. ScanCobot, a mobile automated 3D scanning system, easily integrates with ATOS Q. Combined with an automated robotic arm, the GOM ScanCobot is cost-effective and easy to use. Ideal for a machine shop looking to automate their metrology lab, it doesn’t require a robot programmer to run the unit.

GOM T-SCAN hawk is a compact hand-held scanner that’s designed to capture data whenever needed. It includes technical features such as: photogrammetry of large objects, multiple laser sources and three scanning models. This makes it the perfect solution for fine detail. Thanks to the GOM Inspect onboard, the T-SCAN hawk offers a complete solution to simplify your entire workflow from scanning to evaluation and reporting.

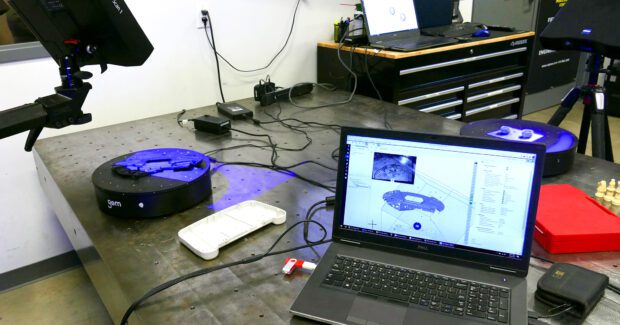

The GOM Scan 1 is a low-cost high-quality scanner with rotary table. It allows users to have some level of automation at an affordable cost. The sensor is built to deliver 3D data with high precision. Easy to operate, the scanner is ideal for simple and fast measurements of small to medium-sized parts, even in confined spaces. With pre-installed GOM Inspect software, users can generate precise meshes and obtain 3D data easily and quickly.

Dean Solberg, Vice President of Metrology at Exact Metrology: A Division of In-Place Machining, believes there are many options for shops, regardless of budget. “We have a full spectrum of high quality scanners at affordable prices. Automated 3D scanning is within reach of the smaller shop reducing labor costs and the need for the skilled inspector.”

In-Place Machining Company: On-Site Machining Solutions In-Place, Any Place in the World.

In-Place Machining Company, with facilities in Wisconsin, Washington, Virginia, Ohio, and Ontario, Canada, is the premier provider of high-precision engineered on-site machining, metrology, and large scale cutting & drilling services for a wide range of renewable energy, aerospace, industrial, and military customers throughout the world.

Exact Metrology: A Division of In-Place Machining Company, is ISO9001, AS9100 Certified as well as ITAR Registered.

Exact Metrology: A Division of In-Place Machining Company, with facilities in Cincinnati, Ohio, Moline, Illinois and Milwaukee, Wisconsin, plus affiliated offices throughout the country, is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements.

Subscribe to learn the latest in manufacturing.