Are you Ready to Succeed in 2023?

The manufacturing sector is conquering challenging headwinds by embracing innovation and collaboration on the road to success.

Posted: December 20, 2022

Bolstered by the quality of solutions-based information and products on display at recent trade shows to support their expansions and overcome their labor woes, the metalworking industry is investing to ensure future success.

Despite ongoing issues such as finding qualified and skilled workers, and with an improving though still challenging supply chain situation, the manufacturing sector continues to perform well, prepared to overcome hiccups.

In the fall of 2022, fabricators and machinists were back in full force meeting face-to-face with suppliers from across the globe and attending trade shows and educational sessions to stay informed of emerging trends, innovations and the challenges ahead.

Trends include opportunities such as the increase in electric vehicles and how it will change the mix and volumes in automotive manufacturing, where more motors and better batteries will be required, as examples. There is also an uptick in sustainability-related initiatives. This month’s cover story, “State of the Industry: Creating a Sustainable Future,” shares a telling figure from a December 2022 report published by the Manufacturing Leadership Council, the digital transformation arm of the National Association of Manufacturing. An overwhelming 90% of survey respondents believed the manufacturing sector has a special responsibility to become more sustainable in the future.

“And this is a sentiment of senior executives already in place,” said Paul Tate, MLC’s Co-Founding Executive Editor and Senior Content Director. “This is not just next generation, green attitudes. Today’s executives recognize there is a great deal of both opportunity and a few challenges along the way.”

Positive Results Shape the Future

The optimism regarding manufacturing is infectious as companies continue to embrace automation and robotics, digital manufacturing (Industry 4.0), and initiatives such as bringing manufacturing back (or plans to research a return) to the United States to prevent supply chain constraints.

Fabricators and machinists continue to share with their suppliers their day-to-day challenges on the shop floor in order to collaborate and ensure products meet their needs. Areas of collaboration include automation, robotics and digitalization of processes.

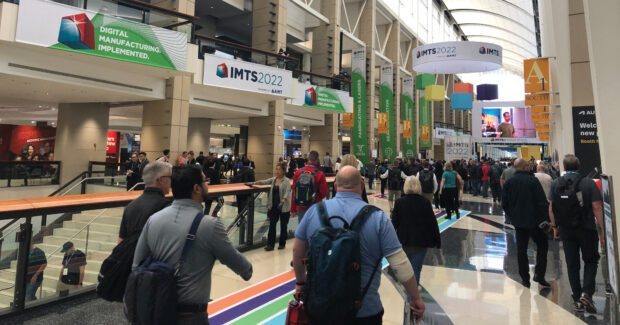

At IMTS 2022, held in September in Chicago, a prevailing topic was that everything is connected. In fact, the show’s theme was “Digital Manufacturing. Implemented.” IMTS offered eight takeaways from the show; and regarding digitalization shared: “You had a hard time finding equipment that isn’t digitally enabled, and many suppliers can help provide integrated solutions that span from designed to finished quality parts.”

FABTECH 2022, held in Atlanta in November, offered more than 150 educational courses. The program spanned 16 technology tracks with sessions focused on automation, smart manufacturing, welding, cutting, lasers, workforce development and more. Nearly 1,200 exhibitors showcased and demonstrated their products; 150 of these exhibitors made their first FABTECH appearances.

In 2023, the manufacturing industry will continue to experience steady growth and overcome challenges thanks to their efforts to innovate and collaborate to achieve success.

www.fabricatingandmetalworking.com

Subscribe to learn the latest in manufacturing.