The HYDMECH Difference Centers on Reliable Saws and Reliable People

From its worldwide leadership in metal band saw and cold saw technology to its long-term, driven employees, HYDMECH’s machines offer users a competitive edge.

Posted: October 1, 2022

SUPPLIER PROFILE

For job shops involved in functions such as welding and fabrication, and general metal processing, doing more with less is an all-too-common theme. In the short term, concerns have to do with the uncertainties of the U.S. (and global) economy, among other issues. And in the long term, finding skilled employees continues to be a leading challenge. As job shops increasingly implement automation and new technologies as the solutions to overcome obstacles, they are constantly working together with their supplier partners to gain a competitive advantage in the market.

The expertise and experience of suppliers makes all the difference when it comes to metal band saw and cold saw technologies. “When you start talking about changes in machines and philosophies in the band saw market, the machines continue to get better and better with technology because the blades continue to get better,” said Rick Arcaro, vice president of sales and marketing for HYDMECH. “Without a good blade your machinery is really useless.” HYDMECH supplies metal band saw and cold saw technologies, and additional metal sawing solutions including a variety of material handling systems to end users.

Arcaro pointed out that when it comes to the circular sawing market, circular saws have evolved into high speed carbide circular machines. As the machines gained momentum, they began taking business away from the band saw machine market due to functions such as automation and features such as the ability to load and unload equipment without an operator. “Then, band saw machines started catching up because of higher technology blades and machines that were able to utilize material handling,” Arcaro added. “Both industries run parallel, and they run together. They compete. We are fortunate enough that we make both.”

HYDMECH, which is part of The MEP Group, is experiencing the largest backlog in the company’s nearly 45-year history. “We are ramping up our manufacturing, improving our processes, and we are growing our businesses,” Arcaro said. “We are doing this at the same time we are dealing with componentry shortages and labor shortages. We have found a way to do more with less — and that seems to be the industry standard. Everyone you talk to — no one can hire people. And everyone is fighting to get ahold of components at every level of every type of product.”

Arcaro said HYDMECH is fortunate that as part of The MEP Group, a division of Groupe Legris Industries, the company’s procurement department can assist each other globally. “Where we could rely on North American suppliers in the past, we are bringing in things globally through other divisions, through other supply chain methods,” Arcaro said.

Arcaro also pointed out the significant changes taking place in the supply chain. It used to be a manufacturer found a vendor it liked, set up an account and the process continued to move forward. Today, companies are on the internet searching for the components (and people) they need.

There are also other changes, including the difference in the level of importance the marketplace places on brands regarding the componentry in machinery. For example, where machine builders would lean toward certain componentry or controllers as an important part of their market strategies, end users aren’t as focused on the brands inside the machinery as they once were. “They need it now and they expect it to work,” Arcaro said. “They’re not going to buy a machine from you because you buy a specific brand; they are relying on the hydmech brand to support [their needs].”

HYDMECH’s World Leading Solutions

HYDMECH is a worldwide leader in metal band saw and cold saw technology, as well as metal sawing solutions. The manufacturer is also a leader in the design and manufacture of metal cutting band saws. Its product lines include double miter band saws; horizontal band saws; horizontal pivot band saws; vertical tilt-frame band saws; vertical contour band saws; circular cold saws; and material handling equipment.

Among the industries that benefit from HYDMECH’s products are aerospace, automotive, steel service centers, metal fab shops and racing. HYDMECH’s customers include GE, the Ford Motor Co., The Boeing Co., and Harley-Davidson Motorcycles.

“Hydmech has always done extremely well in welding and fabrication,” Arcaro said. “Our machines cut structural steel, cutting shapes and angles. We service the welding and manufacturing industry.” He pointed out that both band sawing and circular sawing are extremely fast, for example, serving the chip industries and those that are using machining centers, drills and mills. “We also have horizontal miter machines or verticals that can do whatever a factory needs,” Arcaro said.

One of HYDMECH’s newer machines is the V-2126-APC automatic vertical band saw, with the ability to miter 60° left to 60° right. Arcaro said it is fully programmable with long stroke bar feeds, and it is designed for heavy fabrication activities. The band saw efficiently cuts both solid and structural material and performs different types of sawing applications. “It’s a machine that filled a gap,” Arcaro said. “We had a small capacity and a large and we needed a middle range machine. We introduced it a year-and-a-half ago and it has taken off.”

Another automatic vertical band saw is HYDMECH’s V-18APC-60, which also offers the ability to miter from 60° left to 60° right. It features a left- or right-side infeed, and a 3° fixed canted head allows for more efficient cutting and improved blade life when cutting larger beams, structural steel, and bundles of square tubing. “We had such a good experience with the V-18, a smaller automatic shuttle compound mitering saw that HYDMECH made, we were really dead set on getting another HYDMECH,” said Dee Roskelly of Richards Sheet Metal Works. “What we liked about the V25 is the multiple options for clamping and shuttling, gear box location, its 25-inch capacity throat and how far it could miter both directions.”

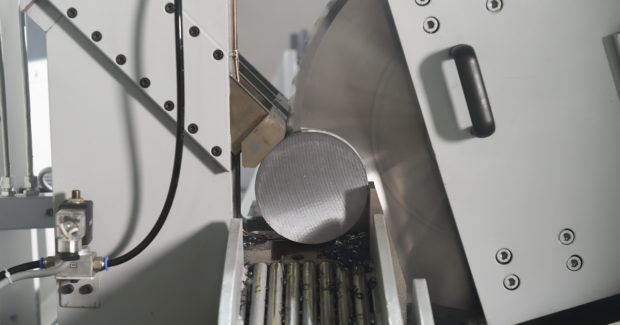

Arcaro pointed out HYDMECH has also introduced a “carbide circular saw line, which are high speed, high end cut off machines that are designed to run around the clock operator unattended.” The CSNC-Series is a high production circular saw that features an automatic bar loading magazine with adjustable incline, programmable part and trim cut lengths, and automatic sorting of trims cuts, remnants and cut parts, among other features. The CSNC-Series cuts four to five times faster than a conventional band saw, with a clean result that rarely requires a secondary operation.

Regarding HYDMECH’s horizontal band saw line, one customer was able to realize faster production times, and an improved capacity to enable scaling up business for its global customer base. This leading U.S. manufacturer of steel products found the HYDMECH H-32A horizontal band saw was the solution that allowed it to cut through the global competition. “We can get extra bundles in there, which can cut production time in half compared with the old machines,” said Art Villafana, warehouse manager, Industrial Metal Supply Co.

The performance and productivity of a HYDMECH saw lead Roadmaster to purchase another machine. “We’ve definitely seen increased productivity of material coming off those saws and in our business,” said Ken Milosevich, plant manager for Roadmaster. “That’s the key thing. The first HYDMECH bandsaw we had performed well, so we decided to get another one.”

Also of note is the performance of the HYDMECH team after the sale. When speaking of parts and service, Arcaro said that for HYDMECH, it is all about ensuring the customer is up and running with the least amount of downtime when it needs parts to repair a machine. “We do sell and stock a fair number of parts to repair our machines but a lot of them [parts in the machines] are industry standard components,” he said. “If someone needs an inexpensive cooling pump, they can go to the local supply house and buy one and not necessarily have to come back to HYDMECH.” It is what separates HYDMECH from the competition, Arcaro noted.

Regarding the delivery of machinery, HYDMECH’s machines are sold through distributors that act as the company’s front line of support. These dealers are geographically and strategically located, and the distributors are factory trained to fix HYDMECH’s machines. Mark Mullen, president of Griggs Steel said that HYDMECH stands behind its equipment. “If there are any problems, they get taken care of immediately,” he noted. “The uptime is very good on HYDMECH saws and that’s good for our business.”

In it for the Long Haul

Another differentiator for HYDMECH beyond its lineup of innovative machinery and trustworthy customer service is what happens behind the scenes regarding its dependable and reliable workforce. The company’s workforce includes several long-term employees who provide an additional level of dependability and consistency in the manufacturing and service process. Arcaro said HYDMECH is approaching 45 years in business and that there are employees who have been with the company since its inception. “I am the youngest salesperson and I have been in the industry since 1985,” Arcaro said. “They love what they do. Their experiences are second to none. Our parts department is second to none. The reactionary time and customer first philosophy is amazing.”

HYDMECH also employs service technicians at its Woodstock, Ontario, Canada and Conway, Ark. operations. Every year these technicians conduct advanced service seminars in mechanical, hydraulic, and electrical systems for HYDMECH’s dealers to ensure the ultimate performance of its saws and material handling equipment.

Arcaro added that when Groupe Legris Industries purchased The MEP Group three years ago it didn’t conduct any downsizing of HYDMECH’s employee roster. “What is refreshing is they came in and bought an extremely profitable organization and let us do what we do, and that is giving them a return on their investment,” Arcaro said. “They made the purchase contingent upon key employees staying. So, they were buying people and the brand.”

HYDMECH’s Unparalleled Network of Sawing Specialists

HYDMECH services the North American market from two centrally located facilities. The Woodstock, Ontario, Canada location is an advanced facility with 200,000 square feet of manufacturing and office space, and the Conway, Ark. facility features 105,000 square feet of manufacturing space. Both locations operate within an integrated network of sawing application specialists and dealers serving North America, Europe, and the Pacific Rim.

“We fall under the umbrella of The MEP Group so we have manufacturing in Italy, China, Brazil and a partnership in Indore, India,” noted Rick Arcaro, vice president of sales and marketing for HYDMECH Group. Groupe Legris Industries, who recently purchased The MEP Group, were so impressed with HYDMECH’s brand and employee base that they purchased the company contingent on key employees remaining with the company.

HYDMECH is a solid and long-running company founded in 1978 in Woodstock by Stan Jasinski. He engineered a better mitering saw; the company continues to pioneer innovations in the industry such as swing-head versatility on its scissors-style saws. The company also continues to deliver a wide range of saws to a variety of industry sectors.

HYDMECH’s innovative solutions and machines have earned a solid reputation in overcoming the sawing challenges of its customers. For Carrell Custom Welding, its HYDMECH band saws enable the company to be the most productive it can be due to cutting speed (torque on the cut). For this company, which owns two HYDMECH saws, one of the saws “saved the day” by enabling the company to bundle cut a large amount of tubing at once.

And while price is the number one driver in a purchasing decision, companies also look at other factors such as reliability. “There’s also the benefit of interoperability, when it comes to teaching the saw operators,” pointed out Edwin Schubrick, operations manager of Howco.

Subscribe to learn the latest in manufacturing.