Next Steps in Tool Presetting

Tool presetters are an accurate way to ensure proper tool dimensions, reducing waste and unplanned down time.

Posted: October 19, 2022

By implementing tool presetters, shops ensure they produce the right part the first time. They provide accurate measurements that reduce scrap and automatically detect tool breakage in CNC machine centers, among other advantages. The presetters are connected to machine controls and provide data so your shop can focus on output and efficiencies.

Probe Systems for Fast and Automatic Tactile Tool Setting

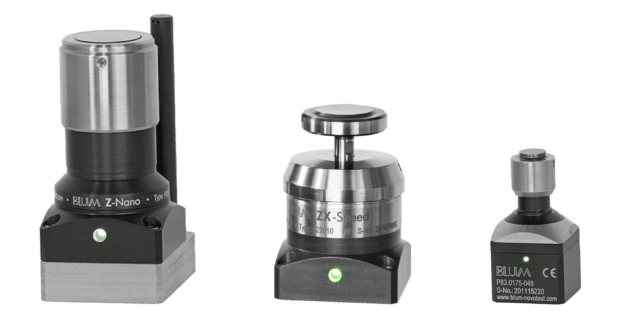

Blum-Novotest, Inc.’s tool setting probes are an accurate, economical way to reduce scrap, down time, ensure proper tool dimensions, and correct tool offset in your CNC machines. The company offers a variety of options to fit most production needs, from simple tool breakage detection to length and radius measurement, and even thermal compensation for milling and turning machines.

Product lines include the Z-Nano, a tool setting probe for tool length measurement and breakage detection. Features include thermal compensation and a wear-free solution with long-term reliability.

The Z-Pico is a compact tool setting probe for small machining centers. It is hard-wired for drill bit breakage detection and tool length measurement. Features include measurement of sensitive and very small tools and thermal compensation.

The ZX-Speed is a universal multi-directional (3D) tool setting probe for tool setting and tool breakage monitoring. Features also include tool length measurement, tool radius measurement and a wear-free solution with long-term reliability.

Other tool setting products include the TC53-20 | TC63-20, a modular tool setting probe for turning machines and turning/milling centers for adaptation to customer-specific tasks. The TC76 is a hard-wired tool setting probe for grinding and turning centers.

Fully Automatic High-end Tool Presetting with Customizable Options

In manufacturing, time is the most expensive component of the process. Microset tool presetting equipment streamlines tool setting processes by reducing setup times, thereby minimizing idle time and increasing machine utilization. Designed for absolute ease of use with uncomplicated software and a stable cast iron base, HAIMER’s (Villa Park, IL) Microset gives machinists the highest degree of accuracy and process reliability. From entry-level machines to fully automated presetting, HAIMER offers a wide range of tool presetting equipment through Microset that will fit every application and budget. The HAIMER Microset VIO Linear is an automatic presetting machine made for precision measurement without errors. It features quick, efficient and easy-to-use operation that allows machinists of all skill levels to produce accurate results. HAIMER’s Microset VIO Linear Presetting Machine reduces setup times by as much as 70%, allowing machinists to increase machine utilization while also streamlining tool-setting processes.

Subscribe to learn the latest in manufacturing.