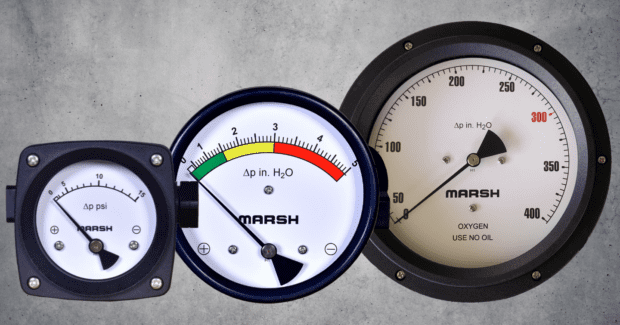

Marsh Instruments Introduces new Line of Differential Pressure Gauges

Differential pressure gauges measure the difference between two inlet pressures in a system using just one instrument, extending equipment life.

Posted: October 26, 2022

Marsh Instruments is introducing a new line of differential pressure gauges, devices that measure the difference between two inlet pressures in a system using just one instrument. They can help extend equipment life and prevent malfunction. These are the first differential pressure gauges backed by Marsh Instruments’ century-and-a-half reputation as the standard of accuracy.

Diaphragm-type and piston-type differential pressure gauges are in stock and available to ship now through authorized distributors. Other configurations will be rolled out soon and can also be manufactured to specific customer demand.

“For the first time, customers in need of differential pressure gauges can get them from the trusted Marsh name,” said Barrett Wall, vice president, sales and marketing, Marsh Instruments. “They can expect a high-quality gauge that is durable, accurate – and in stock. We look forward to continuing to expand our offering to meet the needs of customers throughout our core markets.”

Options include aluminum or 316SS wetted parts, multiple dial sizes of 2.5″, 4″, 4.5″, and 6″, static pressures up to 6000 PSI, inline, bottom, or back connections/ports, and direct, front flange, 2″ pipe, and surface mounting. Maximum/minimum pointer and integrated pressure switches are also available.

Differential pressure gauges from Marsh Instruments can detect clogs, flow abnormalities, and help determine proper system functioning in diverse applications such as oil and gas, irrigation, HVAC, and filtration, as well as measuring liquid levels in cryogenic tanks. Large dial versions are available for use on backflow prevention and test applications in municipal water systems.

Subscribe to learn the latest in manufacturing.