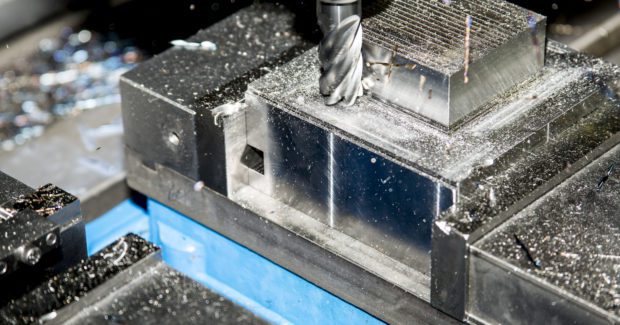

Greenleaf Corp. Introduces Greenleaf-360 High-Performance Solid Carbide End Mills

Greenleaf-360 end mills combine a proprietary flute design with a high-performance carbide substrate.

Posted: October 17, 2022

Greenleaf Corporation has announced Greenleaf-360, a new line of high-performance solid carbide end mills to complement the XSYTIN®-360 line of solid ceramic end mills. Greenleaf-360 end mills combine a proprietary flute design with a high-performance carbide substrate, which allows for fast and efficient material removal with less stress induced into the part. An excellent combination of strength, toughness, and heat resistance enables machining capabilities from roughing to finishing with extended tool life and predictability. Greenleaf-360 high-performance end mills have shown speed and feed performance 25-50% higher than the competition with extended tool life.

Greenleaf-360 end mills use a substrate that has proven capability in a wide variety of materials, from low carbon steel alloys to heat-resistant alloys. The sub-micron grade provides great toughness and wear resistance that offers customers one grade that can be applied in many different applications.

The unique PVD coating that is standard on all Greenleaf-360 end mills provides added productivity and performance. The coating offers a very low coefficient of friction with an extremely high service temperature range. This combination results in high wear resistance and allows for higher speed capabilities, especially in heat-resistant alloys.

“I am extremely excited about the introduction of Greenleaf-360 to our solid round tool offering. This high-performance carbide end mill line provides increased tool life and productivity for our customers, which ultimately leads to increased value. As a world leader in material science and tooling innovation, we worked hard to make sure that our carbide end mill introduction was one of true high performance,” says Bernie McConnell, Executive Vice President – Commercial at Greenleaf Corporation. “The high-performance carbide end mill market opens up a whole new opportunity for Greenleaf to expand our presence and market share in new and existing customers.”

Unique features and benefits of Greenleaf-360 end mills include:

- A proprietary flute design that reduces cutting forces and provides maximum material removal

- Full line of 4, 5, and 7 flute configurations provides solutions from full slotting to high-speed machining

- Extended shank length options allow for effective completion of long-reach applications

- High-performance substrate and coating combination offers versatility in machining various workpiece materials

- Regrind capabilities to like-new condition for added cost savings and value

Ideally suited for machining materials in the aerospace, automotive, die & mold, medical, and power generation industries, Greenleaf-360 inch and metric end mills are available now.

www.greenleafcorporation.com/Greenleaf-360

Subscribe to learn the latest in manufacturing.