Durr’s EcoSealJet Pro Sets Gold Standard for Automated Sealing Processes

The EcoSealJet Pro increases the level of automation and reduces the need for manual intervention during the automotive painting process.

Posted: September 9, 2022

Upstream sealing stations in the car manufacturing painting process are already highly automated. However, sealing is still performed manually for hard-to-reach car body parts. Dürr recently developed a solution to further increase the level of automation and significantly reduce the need for manual intervention. With the new EcoSealJet Pro applicator and improvements in the manufacturing process, maximum precision and consistent quality go hand-in-hand with material savings good for both budgets and the environment.

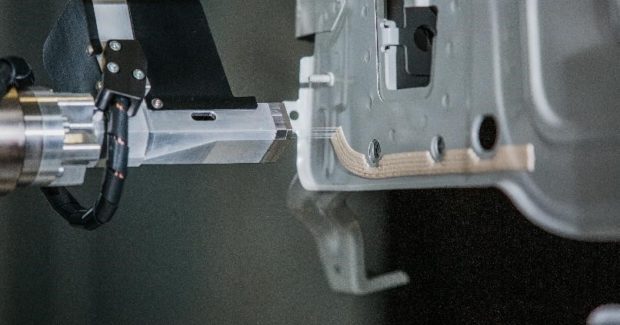

The new EcoSealJet Pro applicator is designed for use wherever automation previously reached the limits of its capabilities. It’s ideal not only for hard-to-access areas, such as in the engine compartment or headlight housings, but also for those areas where automatic PVC application must contend with unusual contours, holes, studs, and other obstacles.

Precise application guarantees results with millimetric accuracy

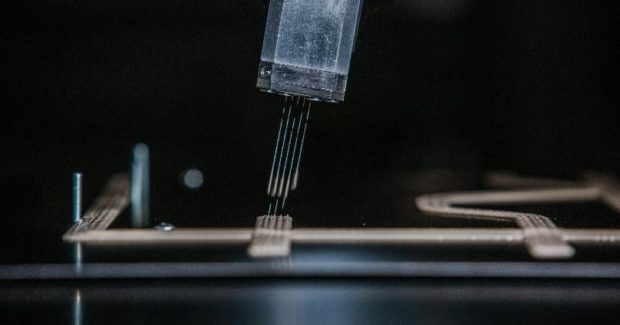

The clearance and work angle of the robot-guided applicator can be variably adjusted to easily access difficult body parts. Its needles are activated individually so that the applicator can apply sealant to the body with consistent precision and quality. Each needle can apply the material in jets or individual drops through the application nozzles – the robot speed and the amount of material determine the variable, high-frequency needle activation making the applicator extremely flexible. It can be used for seam geometries of different densities and widths that – without exception – exhibit a border with high edge definition and no overspray.

Precise application and the ability to adjust material thickness as required ensure no sealant waste. Individual needle activation also prevents material doubling where the seams join. The resulting reduction in material use is an advantage that should not be underestimated, and not only for cost reasons: reduced material thickness leads to lower overall vehicle weight. Since the new applicator can work around add-on parts, studs, and holes, masking and cleaning become obsolete, saving you both time and material. These downstream processes can therefore be reduced or eliminated entirely.

Learning algorithms for overall equipment effectiveness (OEE)

An increased level of automation in sealing is a real benefit, not only for workstation ergonomics but for cost efficiency and environmental protection. Process optimization also plays an important role here. On the one hand, permanent monitoring of individual components such as pumps, temperature controls, dosing units, or valves support optimization. On the other hand, Dürr relies on AI to improve manufacturing processes. The DXQequipment.analytics software package analyzes machine data, detects quality problems in real-time, and optimizes maintenance requirements. This means that future predictions, for example, about a product fault or a plant component needing maintenance, will become more and more precise over time. Intelligent machine learning algorithms support maintenance, resulting in the highest possible plant availability.

Subscribe to learn the latest in manufacturing.