Time to take the Blinders off When it Comes to Tooling Up

As technology continues to advance on the machine side, tooling and workholding offer new and different opportunities to bolster an operation.

Posted: August 23, 2022

The world of metalworking performance is one of trade-offs. Every piece of the chain, from a holder setup to process sequencing, affects something else along the way. The trick is to sacrifice as little — or even gain as much — value as possible with the choices you make. Unfortunately, and misguidedly, tools and workholding are often thought of as the “sacrifice” part of that equation, or just plugging a hole.

The truth is, tools and workholding fall into the small category of devices around a shop that have contact with the parts you’re delivering. By no means is either a small link in the chain. As we’ll see, the tooling you choose today can impact everything from manpower to measuring, bolstering the chain instead of serving as “just another” link.

I talk to a lot of customers who are getting ready for a project or trying to integrate a new machine ASAP. Understandably, they either ask for the cheapest holder they know can get the job done, or whatever they know worked on the old machine. In a high-mix, low-volume environment, this process might work, but that’s not every machine shop, by a long shot.

Instead, most should consider what’s happening around the specific task, a few steps before and a few after, and the potential for other positive tradeoffs when selecting tooling and workholding. Could extending cycle time slightly with the right tools eliminate a dangerous manual operation or guarantee precise measuring the first time? The answer is definitely. Yet, most don’t think this way.

Why do we seem stuck in this rut? One of the biggest culprits holding us back is that we often don’t think in terms of the higher technologies that have emerged in the last decade or so. The speeds, feeds and axes that unlock performance. This also means we don’t have to use collet chucks for everything or shrink-fit chucks just because that’s how it’s been done.

It’s past time to start making tooling and workholding decisions that align with the power and versatility of today’s machines. (The tooling and workholding is ready for it.) Start asking what you can do differently than before. Whether you bought a new machine five years ago or a used one five days ago, have you been using the same old tooling or adjusted to its specs and capabilities?

Streamline Your Operations

Moreso than ever, tooling and workholding are capable of fortifying and streamlining operations. Below are just a few examples of how. Put them to practical use, or use them as inspiration, as you consider your next purchase.

In-process, touch probe measuring is coming on strong across the machining world, and for good reason. By sacrificing a little extra spindle time, we all but eliminate the tedious and time-consuming task of manual measurement. If you’re already probing, don’t sacrifice the all-important reliability of the cycle. There’s no reason you should be hoping the workpiece is clean.

Chip blowers and chipfans add a minute or two of cycle time, but they act as an insurance policy. In addition to automatically cleaning a part, they’ll guarantee that manual or automatic offsets are right, ultimately avoiding significant downtime. These convenient tools are loaded directly into a spindle or tool changer and can be programmed seamlessly into a machining process.

While some might consider our first examples non-essential, this next chain-fortifying solution is more fundamental to the machining process. Zero-point workholding allows you to flip/load parts precisely, perform operations and remove them quickly.

Just to get you thinking: If the capability is there to inspect automatically on a machine, there’s no good reason for sluggish unloading, right? Why, then, opt to use vises or common jaws?

Our UNILOCK workholding system, an example of zero-point clamping, uses spring pressure or manual actuation to clamp knobs in fixed locations for rapid unloading, loading and locating of fixtures and workpieces. Standard knobs can be clamped and mounted in a blind location hole from the bottom or fastened from the top of a fixture.

If ever there’s a chance the machine will be handling a lot of changeovers, especially for automation, trying to be efficient is next to impossible without zero-point clamping and sacrifices to productivity. Again, think about what’s happening around your current situation, before and after buying.

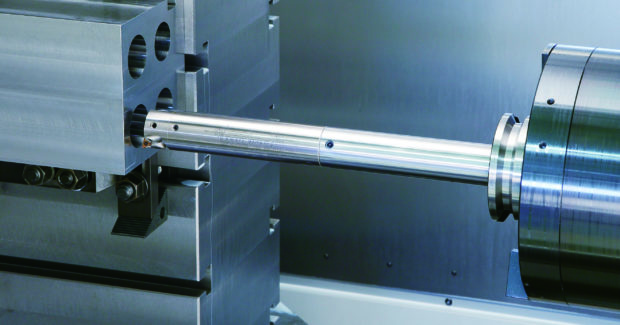

Boring tools and setups offer opportunity for adding value instead of just plugging a hole. Customers are always looking to come up with a universal way for their tools to do more. Their first instinct is to ask for a longer tool, but let’s take a step back with them.

Because we have one of the most versatile modular boring systems at our disposal, the continuously improved CK system, let’s start with the shortest tool and build from there. That way, you have tooling that can do more than one thing and you’re not sacrificing speed every time you use the longer tool.

The same goes for vibration damping in long boring or milling operations. Cobbling together extensions may eventually get the job done the cheapest way possible, but why struggle with it? It’s not worth the trade-off when something like the Smart Damper is available. The integrated design of the Smart Damper system shortens the distance from the damper and the cutting edge, which is the source of vibration and chatter. You can get anything to work if you slow it down enough, but is it worth it?

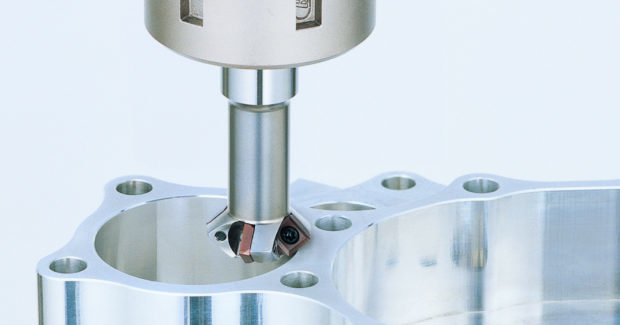

For our final example, let’s turn to a finishing operation. I often hear from customers that they don’t want to chamfer on the machine because it takes up too much cutting time when there are operators that can do it after. It’s a fair argument, but still another example of thinking of cutting tools and holders as conveniences instead of opportunities to add value with the help of today’s machinery.

Hand deburring may seem simple, but it’s not always repeatable. It takes skill and time to hit every single edge with a file or shiv. Even for deburring, better cutting technology is out there. Machines can run around a part much faster than can be done by hand — and then the part’s done.

The C-Cutter Mini is built to the lowest diameter limits in order to optimize chip load and spindle speeds when chamfering small and large features. The cutter can use up to four inserts, and they play a key role. So much so that they are among the only inserts we design in-house: extremely sharp edges with three types of coating reduce cutting resistance to help address speed, finish and force concerns that can arise.

The examples of how tooling and workholding adds more value than ever to the metalworking chain are everywhere. Not each of these may apply directly to something you do, but the approach should apply always — take the blinders off when it comes to tools and workholding. As technology continues to advance on the machine side, tooling and workholding offer new and different opportunities to bolster an operation.

Here are three tips on how to approach tooling and workholding. First, stop thinking of it as just another trade-off or necessary sacrifice for filling a gap or getting one thing done. Two, look at the other technology in the project or job. If everything but the approach to holders or workholding has been adjusted or updated, time to think again. Last, but not least, consider the processes and equipment “around” the task at hand, including future or current work that could be positively impacted.

Subscribe to learn the latest in manufacturing.