Streamlining Metal Additive Manufacturing with Better Build Plate Resurfacing

Advanced rotary surface grinders enable efficient, precise resurfacing of the build plate, improving productivity and quality.

Posted: August 23, 2022

Industries like aerospace and automotive are increasingly relying on metal additive manufacturing (AM) to expeditiously create weight-saving components with complex geometries, different material properties and minimal setup times. To construct each part, advanced 3D printers melt, or partially melt, ultra-fine layers of metal powder on build plates. After each metal part is finished, it is cut from the build plate.

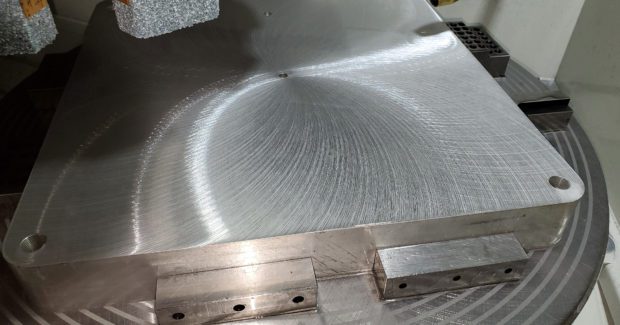

However, one production bottleneck in AM is that any residual metal must be entirely removed before the build plate can be re-used. This requires precisely resurfacing the build plate so that is completely flat, level, and correctly textured prior to printing the next part. Unfortunately, traditional methods of accomplishing this task have significant drawbacks and have become a production bottleneck.

Enter advanced precision rotary surface grinders, which have long been used in metalworking and glass grinding to create perfectly flat, parallel surfaces. The equipment is ideally suited to the AM process and quickly and accurately removes any residual metal from the build plate surface, restoring it to precise dimensions.

The most advanced units even offer automation that allows minimally experienced operators to set them up and then attend to other tasks. This comprehensive approach is helping to exponentially speed build plate resurfacing, boost AM production and improve quality.

“With advanced rotary surface grinders, our AM build plate resurfacing process is significantly more efficient, precise and flexible,” said Doug Hedges, chief technology officer of Beehive3D, Inc. “Incorporating the units in our process will help us handle high expected growth in the AM market.” Beehive3D is an additive manufacturing provider for industries such as aerospace, defense and turbine technologies. The AM contract manufacturer currently has five U.S. locations and is expanding nationally.

Hedges said it is critical in Beehive3D’s laser powder bed fusion process to resurface the build plate to precise process tolerances prior to re-use. “Not only do you have remnants of metal on the build plate, but also portions of the build plate can become bowed or distorted so it needs to be resurfaced after each use to keep it flat and parallel,” Hedges said.

Because the metal part is essentially “welded” to the build plate, it is typically cut off with electrical discharge machining (EDM) wire or a bandsaw. However, both approaches involve removing a thin layer of the build plate surface, gradually reducing its thickness until it is no longer usable. Most of the cuts are not entirely flat or level, either.

The alternative is to cut close to the part, but this leaves material that must be removed later. With EDM and bandsaws, the process can take hours and hard materials like Inconel tend to strain-harden, increasing the difficulty further. Some shops even address the issue with a CNC milling machine, but this can also take hours and limit the availability of the equipment for actual production. Exceptionally hard AM materials like Inconel and titanium further lengthen the required milling time.

Precision Rotary Surface Grinders Improve Productivity

A more efficient alternative utilizes advanced precision rotary surface grinders to remove unwanted residual material with a large rotary grinding wheel surface.

“The goal is to remove just the residual AM part material and as little of the building plate as possible while providing necessary resurfacing of the build plate,” said Erik Lawson, engineering manager at DCM Tech, a designer and builder of industrial rotary surface grinders.

Surface grinders are designed with advanced sensors and controls that automatically maintain very tight tolerances, removing material down to within one ten-thousandth of an inch of the final thickness. The equipment can achieve tighter dimensional tolerances, flatness, parallelism, and surface finish on build plates in much less time than other methods. The process eliminates variability among resurfaced build plates in addition to increasing production and quality, batch after batch.

More advanced units such as DCM Tech’s IG series offer variable speed grinding with automation and controls that allow virtually any operator to successfully manage a unit. These units can control the initial contact between the abrasive wheel and the build plate, which in the past had to be finessed by the operator. Advanced sensor technology detects vibration and can automatically fine-tune not only the pressure of the spindle motor but how quickly it moves the wheel down onto the build plate. When the machine senses the abrasive wheel has contacted the build plate, it automatically begins the grind cycle.

The most advanced units offer simple controls including a touchscreen Human Machine Interface (HMI) that even unsophisticated operators can use to make any necessary adjustments without programming. The HMI controls allow operators to enter virtually any requirement into a touch screen. This capability enhances processing flexibility, so it is easy to adjust any grinding factor to prevent an issue from reoccurring.

For routine processes, the use of a variety of grind “recipes” with sets of parameters for different AM construction builds can further speed production, enhance quality, and aid in quick changeover.

“Different grind recipes can be set for different customers, material types, or construction builds so complex programming or data does not need to be entered at the start of each job,” Lawson said. “A new recipe can be created for job variations, such as a different finish for a specific AM material.”

One aspect that expedites production is the operator’s ability to accommodate grinding of extremely hard residual material like Inconel or titanium from build plates. This typically involves working with an expert vendor that can tailor the surface grinder’s abrasives to accommodate different types of metals and alloys, as well as the materials used for the build plate.

Also important is the ability to alter the parameters through the grind cycle to handle both the printed metal or alloy and the material used for the build plate. The material characteristics of the printed part residue and the build plate are very different, so the rotary grinder must appropriately adjust to each on contact. Once the grinder cuts through the residual part material and reaches the actual plate, the grinding abrasive must work completely differently. The rotary grinders automatically make that transition.

The advanced unit’s grind recipes can also be set to accommodate required build plate textures. This eliminates the need to “roughen up” a build plate in a separate process so the AM part will properly adhere to the surface during buildout.

“Instead of trying to tailor a build plate finish by running it through a mill or an abrasive blaster, after grinding with an [DCM Tech] IG machine there is no reason to take it to a secondary operation,” Hedges said. “An operator can simply clean it with alcohol or a solvent, let it dry, and it is ready to use again in the AM process.”

Hedges said the automation provided by advanced rotary grinders allows operators to setup the machine and then attend to other tasks. The machine does not need to be constantly monitored because it has built-in load monitoring.

“Unlike older style machines, the advanced rotary grinders do not need constant operator input or oversight,” Hedges said. “This allows the operator to multitask and minimizes the risk of error.”

Automation also eliminates the need for operators to manually dress abrasives on the grinding wheel to renew a good abrasive surface. Without automation, over time the wheel can become clogged with residue from the AM material.

When operators manually dress abrasives, on most machines they hold a tool under the grinding wheel abrasive. The tool applies abrasion and knocks off all used or clogged abrasives until the grinding wheel has a nice new abrasive surface. Operators frequently need to repeat the process, sometimes as often as every 10 minutes depending on the materials ground, which can be labor intensive and decrease productivity.

“Advanced rotary grinders with an auto dress option free operators from needing to do it manually, making operation easier and less time consuming,” Hedges said. “The option can be particularly helpful with hard materials like Inconel, which can require more frequent dressing of abrasives.”

As metal AM production ramps up, manufacturers that take advantage of sophisticated, automated rotary surface grinders to efficiently remove excess part materials and resurface build plates will outperform those using slower, less precise conventional methods.

Subscribe to learn the latest in manufacturing.