Sneak Preview: FABTECH 2022

At FABTECH, the metal fabrication industry can tap into the power of this in-person event to discover new innovations and become inspired.

Posted: August 23, 2022

FABTECH 2022 heads to the Georgia World Congress Center in Atlanta, November 8-10! FABTECH is North America’s largest metal forming, fabricating, welding and finishing event. At this all-encompassing gathering, attendees can meet face-to-face with world-class suppliers, view demonstrations of the latest industry machinery, products and services, discover new ways to increase productivity, and so much more.

In addition to an extensive exhibition hall, FABTECH also features conference programming that offers targeted technical, operational, economic and managerial sessions, as well as continuing education credits. Expand your skills and knowledge, learn from experts, discover new tips, network with industry peers and gain tools to maximize production within your shop.

Bluco® Modular Fixturing Systems Solve Manufacturing Challenges

Explore modular solutions and real-world results in Booth C12417 where Bluco Corp. (Naperville, IL) designers and manufacturers of modular workholding solutions, will give visitors a look at the results being achieved by customers, and a roadmap to unlocking similar benefits for themselves.

Bluco will illustrate how its modular fixturing systems help deliver shorter production times, better final part quality, and reduced manufacturing costs. In addition, Bluco’s application engineers will be on hand to chat with visitors about the end-to-end welding, positioning and robotics solutions Bluco is best known for.

Bluco Modular Fixturing Solutions for Welding

For visitors wondering what separates a workbench from a modular fixturing solution, Bluco’s booth is the place to find answers. Learn how customization and manufacturing expertise combine to create full systems that go well beyond what simple welding tables offer. Among the success stories highlighted in the booth will be:

- Parts finished 28 days faster

- Production doubled, 1/16” tolerance maintained

- Process changed to shave 50% off construction time

Bluco Modular Fixturing Solutions for Positioning

Booth visitors will learn how application engineers combine best-in-class positioning technology with Bluco’s modular tooling to greatly enhance safety and comfort while positively impacting overall operations, to achieve results like these:

- 10% cost reduction

- 7 times greater accuracy

- Bid won due to modular speed and flexibility

Bluco Modular Fixturing Solutions for Robotics

For manufacturers who implemented robotic automation but didn’t get the bump in efficiency and precision they expected, Bluco modular workholding solutions can often be the missing piece. Application engineers will share how they helped to deliver:

- ROI too high to calculate

- Sluggish automation brought up to speed

- 32 setups from one solution

Booth C12417

Cloud-based ERP Platform Streamlines Operations and Boosts Profitability

Epicor will showcase its cloud-based Epicor Kinetic ERP platform for manufacturers in Booth BC15325. As manufacturers contend with an array of challenges including operational efficiency, supply chain disruption, workforce complexities, and changing customer expectations for digital connectedness, the need for flexible, insights-driven industry productivity solutions has never been greater.

Epicor Kinetic addresses these challenges head on, offering an intuitive user experience that empowers customers with deep industry-specific capabilities, integrations, and business process automations manufacturers require to grow their businesses and boost profitability. That includes optimizing manufacturing operations; gaining greater control, insight, and visibility into global supply chains; and leveraging low-code/no-code business intelligence capabilities to make better decisions across the enterprise.

Earlier this year, Epicor introduced Epicor Automation Studio, an integration Platform as a Service solution embedded within Epicor Kinetic that empowers citizen integrators to connect data and automate workflows both within Kinetic as well as with more than 1,000 applications and databases.

Additional Kinetic updates include:

- Epicor CPQ which streamlines production through visual product configuration, dynamic pricing, document generation and more. Updates also provide richer integration points across Epicor CPQ for quoting, sales orders, and jobs allowing businesses to improve operational efficiency.

- Epicor Commerce Connect is a cloud-based, fully integrated, omnichannel digital commerce system that seamlessly integrates your online store with Kinetic. www.epicor.com

Booth BC15325

All New Hypertherm Plasma, OMAX Waterjet, and Software Products

Hypertherm Associates (Hanover, NH), a U.S.-based manufacturer of industrial cutting products and software, will showcase the company’s Hypertherm and OMAX technology brands, offering a comprehensive array of plasma and waterjet products. Visitors to Booth B8309 will have an opportunity to see the world’s only X-Definition plasma and a new HPR cartridge for HPRXD plasma systems. In addition, they can see the OptiMAX, considered the world’s most accurate waterjet, along with the ProtoMAX, a compact, self-contained cutting system perfect for prototyping and low volume cutting. Hypertherm Associates will also feature its ProNest CAD/CAM nesting software, providing show visitors with live demonstrations of its recently released ProNest 2023.

Powermax air plasma products, including the innovative Powermax SYNC plasma with built-in intelligence and a single-piece consumable cartridge, will be available in Booth B11237. Attendees will have the opportunity to try the Powermax SYNC and its SmartSYNC torch. They can also meet Metal Artist, TV Personality, and Author Rae Ripple, who plans to unveil her newest creation, an intricately cut vintage car hood that she made with her Powermax65 SYNC.

Finally, from Booth C10827, Hypertherm Associates will exhibit its Robotmaster offline programming software for robots. The Robotmaster team will demonstrate new software that bridges the gap between CAD/CAM and robotics by enabling seamless integration between a user’s chosen CAD/CAM software and Robotmaster.

Booths B11237, B8309 and C10827

Eliminate Laborious Bin Picking Tasks with Kawasaki’s New Robot

Bin picking processes are known to be laborious, tiring, and even dangerous in some situations. These tasks are suited for automation but can be challenging to automate because of the random orientation of parts.

In Booth C11337, Kawasaki Robotics (Wixom, MI) will display an automated bin picking solution that can save users both time and money while streamlining their operations. The solution combines Canon’s leading optical processing technology and Kawasaki’s new RS013N general-purpose robot for picking and sorting random parts from a bin to a conveyor.

Kawasaki Robotics’ dedication to product quality is evident in its next generation of R series general-purpose robots. The industry-leading RS013N builds on the momentum started by the RS007N/L models in 2017 by offering a 13 kg payload capacity, a small footprint and a lightweight IP67-classified design.

The RS013N robot’s design includes a new arm structure and lighter main unit, which enables high speeds and a large working area. Its 1,460 mm reach is the largest in its class, allowing for installation flexibility and use in a wider variety of applications. The RS013N robot also leads its class in speed, resulting in reduced cycle times and increased productivity.

Kawasaki’s new R series robots are also designed with ease of use and longevity in mind. The motor has been moved and covered to protect it from harsh environments and workplace wear, and the new motor location on the base allows for enhanced protection and easier serviceability.

Booth C11337

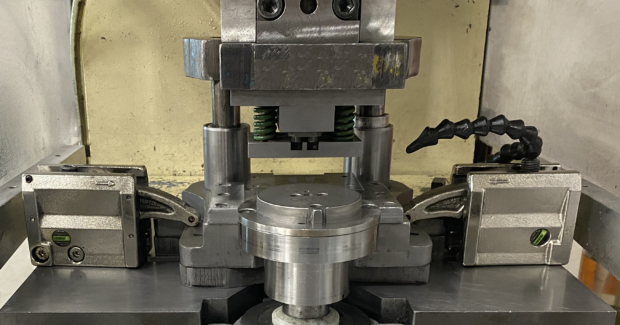

Quick Setup Tools Save You Time

With more than 45 years of experience and more than 100,000 satisfied customers worldwide, Lenzkes Clamping Tools (Christiansburg, VA), located in Booth B5647, is known for its high-quality workholding solutions. We assist companies involved in the metal and plastics industries review working principles, safety issues and reduce downtime in their facilities. With a vast

variety of tooling available, we believe we can fit your company with a product that will be

beneficial for your company’s individual needs.

The Lenzkes Difference:

- Clamping solutions for all types of machines

- Strong clamping pressure for small clamping torque

- Fast clamping, short setup time, quick release action

- Stepless adjustability horizontal and vertical

- Upon request available free of charge on a trial basis

Multi Quick 200

- Belongs to Lenzkes wide variety of Multi-Quick Tools designed for respective applications.

- Large stepless horizontally and vertically adjustment.

- Strong clamping pressure for small clamping torque.

- Quick setup equals time savings.

- Suitable to be used for metal forming, metal cutting and injection molding.

Clamping Frame S33

- Clamping Frames made from hardened alloy steel, drop forged.

- Stepless vertically and horizontally adjustable due to the unique grooved frame design (S33/45).

- Suitable to be used for metal forming, metal cutting and injection molding.

Booth B5647

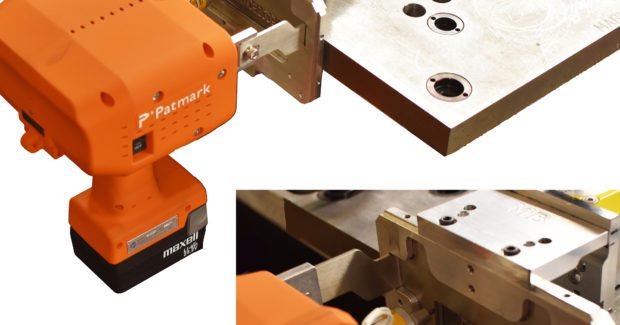

New: Quick Change Fixture for Side of Plate Marking

New for 2022, MB Metal Technologies, LLC (Milwaukee, WI) introduces the Quick Change Fixture for Side of Plate Marking, for both MarkinBOX and Patmark Dot Pin Marking Machines. See a live demo in Booth BC15318. The new equipment is available in two Marking Window Sizes; 15 mm x 33 mm, and 20 mm x 80 mm. Quickly and easily position your MarkinBOX or Patmark Dot Pin Marker, and securely fix your marker in position to mark the side of your Tool Steel Plate (up to 62 HRC). Includes both a machined aluminum quick change plate for mounting your Pin Marker, as well as a 450 pound on/off magnet, for easy and strong mounting to the tool steel. The fixture is fully adjustable, and easy to use.

Booth BC15318

New Levels of Tube Bending

Unison Tube LLC (Danville, VA) will present several innovative tube manipulation technologies in Booth C10217. Unison machines on display will include an all-electric Breeze Twin Head tube bending machine and one of the company’s all-new Synergy hybrid, multi-stack tube benders. Unison will also use FABTECH to launch the most advanced version ever of its industry leading Opt2Sim tube bending simulation software, with several free software licenses up for grabs.

Unison’s Breeze Twin Head is equipped with the company’s recently upgraded Unibend control — an operating system offering speed enhancements of up to 25% — all-electric Unison Twin Head 1-½” (maximum tube diameter) machines will precision bend two ends of a tube simultaneously. This capability makes them well suited to the high-speed manufacture of symmetrical tubular shapes typically found in automotive, agricultural and furniture applications.

Unison also offers the new Synergy machines, which combine electric and hydraulic operation with exceptional levels of control. Developed for organizations that aspire to Unison quality but carry out repetitive tube bending tasks, Synergy models provide a highly accessible entry point into the Unison range. Available in 2” (50 mm) and 3” (80 mm) versions, Synergy machines feature a servo-driven bend arm, carriage, plane of bend and carriage side shift, with a hydraulically controlled mandrel, pressure die and clamping system. This is a combination that Unison believes make its Synergy range perfect for high volume, repetitive tube manipulation operations.

Continuous innovation has ensured that Unison’s Opt2Sim remains a favorite tube manipulation software program among users of Unison and other brands of tube bending machines. The latest iteration of Opt2Sim makes it easier than ever to import and extract tube data and includes software versions that take simulating the bending process, creating batch files and scanning tube coordinates to the next level. Opt2Sim provides users with a complete end-to-end solution, from taking 3D STEP files to bending tube within a single software suite.

Booth C10217

Redefining How Companies Share Knowledge with the Workforce

It’s time we enhance the knowledge-sharing capabilities of the workforce. As the manufacturing sector is becoming smarter and more diversified, workers need the tools to evolve with it. Visual Knowledge Share Ltd.’s (VKS) (Châteauguay, Québec) work instruction software is pursuing this goal by enabling companies to centralize their tribal knowledge and easily share it with their employees. VKS will be in Booth B9615.

“Digital work instructions are changing the way people share knowledge with the next generation of workers,” said Ryan Zimmermann, VKS director of business development. “By capturing the knowledge and experience of senior operators and talented engineers, VKS allows companies to isolate their best processes and guarantee they are followed every time. This technology is a tool for companies to ensure ongoing success in the future.”

Through work instruction software, companies can capture the best practices of their most experienced employees. As a result, every employee has access to the greatest level of expertise and experience, making every worker your best worker. By utilizing interactive and visual step-by-step work instructions that guide workers through their daily tasks, inexperience is virtually a thing of the past.

Modern manufacturers using this technology have improved productivity by more than 20%, enhanced visual standardization, and decreased their training times by 75 percent. “Our orientation process has been cut down to a quarter of the time it used to take,” said Adrian Riojas, an engineer for KONE Coal Valley Manufacturing. “VKS helps us give new operators a point of reference first so they know and get familiarized with the terminology on the floor. It’s been a godsend to get a uniform language going.”

Digital work instructions are crucial for high-mix, low-volume manufacturers as well as companies that are vertically integrated. Through pictures, annotations, production alerts, and smart forms, every worker receives access to the right knowledge every step of the way.

Booth B9615

The Next Step in Press Brake Productivity

In Booth B6346, WILA (Hanover, MD) will showcase the WILA AirPower Series, among other products. The AirPower Series offers a complete range on WILA’s pneumatic locking tool holders, top and bottom. The products speed up operations and tool changes, which maximizes productivity. Thanks to the patented Self-Locking mechanism, the WILA AirPower Series ensures superior clamping performance. Tools are clamped and unclamped extremely fast and tight, using only regular workshop air pressure of 6-8 bar — without the need for expensive pressure boosters. Tools are clamped and locked using a pneumatically controlled pair of self-adjusting wedges. When the wedges are engaged (clamped), they become an integral part of the tool. The Self-Locking principle is suitable for clamping WILA’s new Standard top and bottom tools (BIU and OZU). The Premium clamping is also released pneumatically.

Benefits of pneumatic clamping with the WILA AirPower Series:

- No oil, no hydraulics

- For top and bottom tooling

- No pressure booster needed (87-116 PSI will do)

- Ultrafast clamping for more productivity

- Lower operating costs

- Cleaner, more sustainable

- For new and existing press brakes

For more than 85 years, WILA has been developing and manufacturing high-end press brake clamping systems and tools for press brake manufacturers and users.

Booth B6346

Subscribe to learn the latest in manufacturing.