New Tool-changing Options Deliver Accuracy and Safety for Users

Versatile and robust robotic tool-changing applications optimize your shop’s processes.

Posted: August 24, 2022

TOOLING & WORKHOLDING

Robotic tool changers make operators’ lives easier by creating lightweight and durable products that maximize efficiencies within your operation.

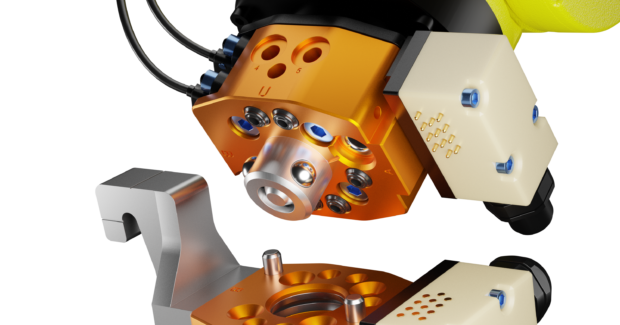

Compact Robotic Tool Changer and Safety and Control Module from ATI

ATI Industrial Automation offers the QC-7, a feature-packed solution for automatic exchange of end-effectors, as well as the CV14 Safety and Control Module. The QC-7 Robotic Tool Changer is a new standard robotic tool changing and storage solution. It is a lightweight yet durable tool changer that offers a variety of configuration options with ATI’s Pass-Through Utility Modules and Tool Stand systems. An optional ML12 Electrical Module attaches easily to the QC-7 Tool Changer body, which also includes five pass-through air ports and lock/unlock air fittings. The tool changer features a low stack height and mounts directly to ISO 9409-1-31.5-4-M5 robot wrists. It is compatible with ATI’s modular Tool Stands and has an optional tool storage hook to make robot programming easy.

The pneumatically actuated QC-7 features no-touch locking technology and a patented fail-safe locking mechanism for a secure connection between the master and tool. The design integrates lock/unlock sensors without the need for an additional interface plate. This tool changer handles payloads up to 35 pounds (16 kg) and is compatible with variety of industrial and collaborative robot models.

ATI has also developed the CV14 Safety and Control Module to provide signal control and communication to tool changing applications. Control modules are a safe efficient way to pass controls signals through the tool changer to the end-of-arm tools and allow users to verify processes and monitor an end-effector’s status without entering the work cell. The CV14 also includes a variety of additional features like built-in safety, tool identification, connections for lock and unlock sensors, and an integrated pneumatic valve that can help streamline equipment needs and make the implementation process easier. It is ideal for robotic applications with payloads of 165 kg or less and is compatible with ATI’s Tool Changers and Tool Stand products, for models ranging from QC-29 to QC-110. Like many ATI Control Modules, the CV14 includes Tool Stand Interlock capability, which helps to prevents accidental tool release by ensuring that the robot does not uncouple end-of-arm tools unless they are supported in the Tool Stand. The compact CV14 promotes safety and increased uptime of smaller robot applications by minimizing hazards from released tools.

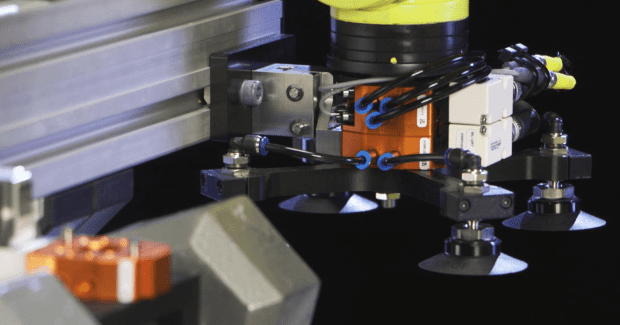

Destaco Introduces Quick-Install Tool Changer for Cobots

As the use of cobots in part-locating applications continues to expand, new tool-changing options offer improved versatility, accuracy and safety for users. Destaco has expanded its diverse robotic-tooling portfolio with the development of the ultra-compact and lightweight TC1 Series manual tool changer. Weighing only 330 grams (11.6 ounces) with a low-profile height of 25 mm (1”), the TC1 tool changer has minimal impact on cobot payload capacity. The TC1 ultra-light, rugged tool changer with push-button release allows a tool change in less than three seconds with no physical strain placed on the operator. Positional coupling repeatability of 0.025 mm (0.001”) helps to ensure that established cobot part placement programming accuracy remains intact after a tool change. Integrated safety features include a visible red indicator when the tool is not properly coupled or locked into place. Each tool changer has its own mounting hardware and tools to bolt directly to a cobot without additional adapter plates or mounting hardware.

The TC1 is usable as either a tool changer or as a test-station coupler and benefits from having three robot/tool-plate mounting options. These solutions include: 1) an ISO 9409 mounting pattern that mounts to any third-party cobot tool with the same ISO pattern, 2) a DirectConnect option for mounting Destaco’s Robohand family of products, and 3) a blank tool plate for users who wish to machine their own custom mounting patterns for both cobot or tool-side operation.

The TC1 also has four integrated pass-through air ports plus optional electrical pass-through modules that connect directly to the UR robot arm or tool with the same connector for pass-through electrical operation. When using multiple tool plates, an optional tool holder is available for easy tool-plate storage when the tools are not in use.

New Automatic Tool Changer for 24R CNC Router

Tormach Inc., the industry’s leading supplier of affordable and compact CNC machines, offers a new Automatic Tool Changer (ATC) for its 24R CNC Router. The ATC features an ISO20 ATC Spindle with a 10-tool rack and automatic lifting dust shoe. It is a valuable addition to the 24R CNC router and is integrated into Tormach’s award-winning PathPilot CNC controller. The 24R is designed to accurately cut a wide variety of materials. With an advanced control, rigid cast-iron bed, welded steel stand, water-cooled chiller, integrated vacuum table, and more than a 2’ x 4’ work envelope, it is the perfect choice for 2D and 3D cutting needs.

The ATC also features repeatable tool lengths, which provides faster tool changes. The new lifting dust shoe feature allows users to check the router’s cutting action while the machine is running and leading into a cut.

Subscribe to learn the latest in manufacturing.