Manufacturing Challenges Spur Ongoing Machining Advancements

Shops rely on the latest technologies to make it faster, better, cheaper.

Posted: August 23, 2022

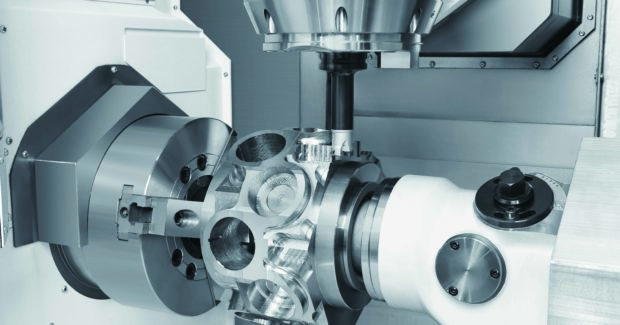

Competitive challenges within the manufacturing industry have traditionally driven the evolution of machining technology. That evolution continues today on a wide variety of fronts. Those include full simultaneous 5-axis machining, conventional and hybrid multitasking technologies, machine control functions, software, automation and advanced service and support programs.

As parts increased in complexity, the development of full simultaneous 5-axis machining boosted production speed and accuracy, and in some cases was the only way to produce especially complex parts. On a machine tool, 5-axis technology improves on basic X-Y-Z tool positioning by adding A-axis and B- (or C-) axis movement, allowing the cutting tool to approach the workpiece from multiple directions without refixturing the work.

Early 5-axis machines were expensive and required advanced programming and operator skills, limiting their use to facilities with esoteric capabilities and resources. Recently, machine tool builders have developed 5-axis machines that are easier to program and represent a reasonable investment for smaller shops, especially in terms of the value the machines provide.

Initially, a machine tool was engineered to perform a specific operation such as turning, milling or drilling. Today, multitasking machine tools perform a variety of operations in one fixturing on a single machine platform, saving the time and effort otherwise spent moving parts among machines and refixturing them between operations. Multitasking eliminates inaccuracies that occur during the refixturing process. Optimal use of multitasking machines also minimizes work-in-process that otherwise accumulates while parts are moved among standalone machine tools.

Multitasking machine configurations have progressed from systems that combined simple milling and turning operations to those incorporating advanced components and capabilities including twin turning spindles, multiple tool turrets with rotary tool stations and Y-axis off-centerline machining capabilities. Some machines also offer tilt/rotary B-axis milling spindles, rotary/tilt tables, large capacity tool magazines and full simultaneous 5-axis part processing.

Multitasking technology continues to add capabilities as today’s machine tool builders work to refine and improve upon machine designs and capabilities. Increased processing versatility further enhances the core benefits of multitasking, allowing manufacturers to accomplish more with less and boost competitiveness.

As a pioneer in multitasking technology, machine tool builder Mazak has further broadened the concept with developments like its HYBRID Multi-Tasking that combines additive processes such as direct metal laser sintering and hot wire weld deposition with conventional subtractive manufacturing operations. Another innovative approach combines conventional machining with the Friction Stir Welding (FSW) material joining process. Such HYBRID systems advance Mazak’s Multi-Tasking DONE IN ONEÒ part processing concept to another level of single-machine part processing.

Customizing Production Flow

In many manufacturing scenarios, machining strategies have shifted from mass production of identical parts over long periods of time (high-product volume, low-product mix) to flexible output of a variety of smaller batches. The goal is to minimize inventory costs and speed engineering modifications, thereby enabling production to be customized to meet specific market demands. The advent of digital technology in programming, machine controls and automation systems now permit efficient handling of cost-effective high-mix/low-volume production.

Machine Control Development

Machine control technology development trends reflect the needs of differing end users. For example, Mazak’s MAZATROL programming system provides versatility and user-friendly operation by allowing both G-code and conversational programming capabilities, permitting off-machine programming in addition to conversational programming by an operator on the shop floor.

For lesser experienced shop personnel, conversational programming time can be 75 percent faster when compared to machines using EIA/ISO systems. This makes controls offering conversational programming especially effective when processing workpieces that require only simple turning, milling, drilling and tapping operations.

In a most recent trend, machine tool builders like Mazak are offering CAD/CAM software that can be more easily integrated with machine tool controls. This allows shops to generate accurate part program simulations to reduce prove out times and greatly improve the probability of producing a good part the first time. Benefits extend to highly complex applications requiring multitasking operations, full simultaneous 5-axis machining and the incorporation of automation.

When CAD/CAM software works together with machine tool controls, shops gain the ability to generate a variety of programming options, streamline data entry and reduce their programming time. For example, Mazak is developing an Application Programming Interface (API) that allows CAM software providers to seamlessly access data from Mazak machine controls. The CAM software can utilize that machine data to generate extremely accurate part program simulations. Because the simulations are based on the machine’s native data, simulated operations can reflect exactly what will occur in the actual machining scenario. Such virtual machining simulations provide convenient program error detection and machine component interference checks.

To make the interface effective, Mazak provides the same information used by its machines to the CAD/CAM suppliers. Software provider engineers then use the data to make their simulation graphics much sharper and precise and tie them directly into their CAM systems. Equally important, the common interface keeps machine controls affordable and cost effective.

The connection between the CAM software and the machine control allows shops to produce programs that take into consideration the specifics of the machine being used and how it operates regarding capabilities, kinematics, tooling and range limits. Without this exact machine data, software designers can only estimate a machine’s true capabilities.

Automation Alternatives

Machine tool builders and independent suppliers have developed automation systems to streamline production and maximize machine utilization by expediting delivery of raw material to the machine tool and handling finished parts. Automation system complexity and expense typically varies in line with the complexity and expense of the parts being machined. At its most basic, automation for a turning center can consist of a bar feeder and a parts catcher. On the other hand, a large automated production system can effectively be a factory in itself, comprised of a flexible manufacturing system linking a variety of machine tools, robotic or palletized loading and unloading systems, and material handling and storage systems with conveyors, automated guided vehicles and digitally managed storage systems.

Gaining maximum benefit from machining automation requires full integration with a facility’s operations. For many simple, single-machine situations, the addition of separate off-the-shelf components can be successful. Initiating a larger system, however, is usually preceded by a thorough examination of a company’s manufacturing operations and business as a whole, taking into consideration current market conditions as well as alternate possibilities for the future. It is not a do-it-yourself operation. Working with an automation integrator or large machine tool builder who can specify pre-engineered or custom automation system designs will produce the best outcomes in both the present and the future.

Beyond Metal Cutting

Advances in machine tool technology are not confined to actual cutting operations. An example of in-process technology is probing capability that permits part identification and accurate part loading and can provide real-time gaging for ongoing quality assessment. In essence, on-machine probing can provide inspection data similar to that from a Coordinate Measuring Machine (CMM).

With today’s scanning probes, for instance, shops can “sweep” a surface or bore much faster than with older-style touch probes and collect huge amounts of data while doing so. This results in increased measurement accuracy because the probe contacts thousands of additional points on the workpiece. For some shops, on-machine scanning probes offer an alternative to purchasing a CMM or having to send parts out for inspection.

Today’s machine control technology improvements extend to process monitoring and other advanced functions, such as those incorporating Artificial Intelligence (AI). One example is Mazak’s Ai Thermal Shield function. The system uses machine learning and modeling to immediately compensate for changes in machine and ambient temperature over the course of operation to maintain accuracy even over long machining cycles.

Upgraded Support

In parallel with boosting machine tool accuracy and productivity, machine builders increasingly provide enhanced customer service and support programs that enable users to maximize utilization of advanced machining technologies. For example, Mazak’s MPower program provides direct, real-time access to a multitude of support options including expedited replacement part ordering and service scheduling. Assistive programs include expert technical service through remote assist services, on-demand training with a learning management system, cost-effective spindle rebuild services and local support from a network of technology and technical centers.

Subscribe to learn the latest in manufacturing.