Spindle Speeder an ‘Eye Opener’ for Fishing Lure Maker

By using BIG DAISHOWA’s RBX7 Air Power Spindle for its primary machining process, the operations decreased from 75 to 15 hours, which was transformational.

Posted: July 5, 2022

Fish aren’t as dumb as they look. They won’t just bite on any lure. The shapes, colors, sizes and sounds lures make have to be just right — and ultimately worth the fisherman’s money and trust. That’s where American Baitworks comes in. In addition to rods, apparel and tackle for fishermen, the Mississippi company distributes a family of well-recognized lure brands across the world.

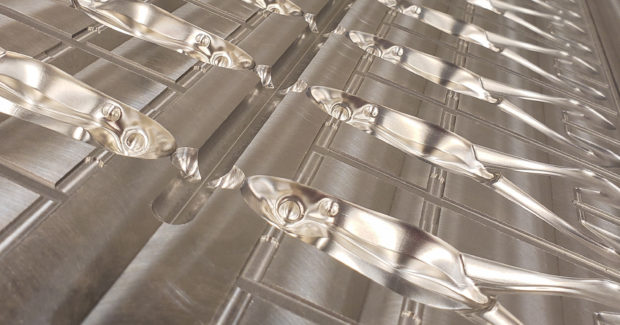

American Baitworks uses a soft-plastic injection molding process to create a large portion of its offering. Two large blanks of standardized 6061 aluminum are machined using a delicate .031″ ball mill, each with one half of a flat mold. The two machined plates are then put together and the opposing cavities, typically somewhere between .375″ and .625″ deep, form the full mold where soft plastic is injected to achieve the near-complete bait.

While this would be considered production work by many, there is nothing simple or all that repetitive about the machining leg of the process. With such tiny detail, hundreds of cavities in each mold, more than 20 million lines of G-code and spindle speeds limited to around 12,000 RPM and feed rates of 36 IPM, some single plates were taking up to 75 hours to complete.

While reliable, the process had proven very time consuming. The team set out to find a way to increase speeds and feeds without sacrificing the precision and reliability needed. With a single machine tool on the floor, one of the best options appeared to be a spindle speeder. Once that was decided, the decision had to be narrowed down just a bit further: air- or coolant-driven speeder?

“Everything in our facility is run off of air,” American Baitworks Warehouse Lead Manager, Ladd Flurry, said. “We have two 70-CFM compressors that keep up very well. I was leery of air-driven speeders. I didn’t want to take any CFMs away from the manufacturing area during the regular workday.”

Coolant was the call and initial results were promising. RPMs exceeded 40,000, feed rates reached 60 IPM and instead of 75 hours, plates were being machined in 20-to-25 hours. Mission accomplished, right? Not quite.

“We had certain troubles with it,” Flurry said about the coolant-driven speeder. “The coolant had to be filtered very well. Coolant pumps wouldn’t always cooperate, and it wasn’t equipped with a full duty-cycle motor. If we were running lights out, I felt obligated to come back several times throughout the night. I was uneasy about it. We needed something more reliable.”

Enter recently hired machinist, Justin Saegert. He suggested using an air-driven speeder instead of the coolant-driven style. In this scenario, the machine spindle does not rotate at all, the machine is merely moving the tool from one position to another. The drive is within the tool itself. The air enters the stop block through the position pin, and into a turbine drive. The turbine drive then transfers the torque and speed to the cutting tool.

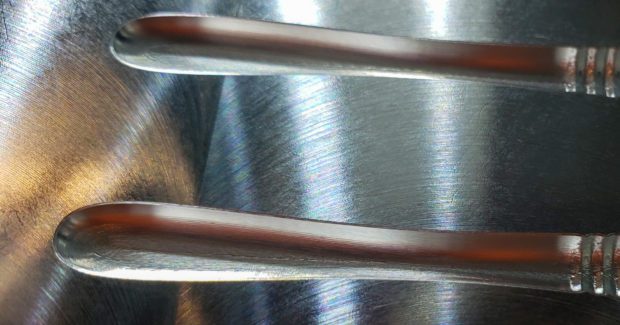

New to both Flurry and Saegert, they invited BIG DAISHOWA representative Neal Wilson to demonstrate the RBX7 Air Power Spindle on their machine. Spindle speeds easily reached 60,000 and approached 80,000 without losing control or breaking the small cutters. The difference in surface finish made a major first impression. “The difference was clear, an astronomical difference,” Flurry stated. “When compared to parts coming off the coolant speeder, one was a mirror, one was a foggy mirror.”

The visit also put the team at ease when it came to CFM consumption. Where other air-driven products needed upwards of 20 CFM, the RBX7 only needed six. “I was not comfortable taking 20 CFMs away from my manufacturing area to put on a small speeder,” Flurry explained. “But six or seven, that’s nothing. We can do that all day long.”

Flurry agreed, the RBX7 was the call. While reliable throughput was the ultimate goal of the change, Saegart experienced other exciting improvements as a result of the air-powered spindle firsthand at the machine.

“With the RBX, you don’t have the atomization of the coolant escaping from the machine shell itself and fogging up the workspace,” Saegar said. “There’s a big noise difference too. Since we aren’t running the high-pressure pumps for the speeder, the decibel level is a lot lower.”

It’s undeniable that the coolant-driven speeder delivered much-improved efficiency when it was fully engaged, but even those results were improved upon. With RPMs up to 80,000, feed rates almost double to 110 IPM without any increase in tool wear. The same sets of molds that took 25-to-30 hours, now take 12-to-16. When the primary machining process of an operation is reduced from 75 hours down to 15, it can be transformational.

“It’s a huge savings in man hours and we’re able to produce more molds each year than before,” Flurry said. “It’s been a big eyeopener for our company. If you can increase reliability, something as impactful as the RBX7 is a no brainer for a production facility.”

The midnight checkups have become a thing of the past. “The uneasiness has faded,” Flurry said. “With the RBX7 consuming so few CFMs, I can tailor my machines to kick on and off at different set points. I can leave here whenever, lock the building up and not have to come back until the next morning. We turn on the machine and run it for 20-plus hours with no hiccups.”

Subscribe to learn the latest in manufacturing.