IMTS 2022: Quality Assurance

Check out the metrology equipment and systems that keep your processes on track, as well as equipment that checks the accuracy of your machines.

Posted: July 20, 2022

New Smart Technology for Lights-Out Machining

In Booth E-135736, Caron Engineering (Wells, ME) will feature its latest technologies for automation, cycle time reduction, unmanned operations, and total process monitoring and control for tool loading, offset adjustment and more. The company’s technology outfitted on a Tsugami TMA8 live-cutting demo will showcase a fully automated (lights out) manufacturing process.

The highlighted Caron Engineering technology will include:

- ToolConnect: Before cutting, Caron Engineering’s tool data management system, ToolConnect, will automate the process of loading tools into the machine. It reads and processes presetter written RFID tags, and 2D printed barcode tags to automatically update tool information directly to the CNC control, and further prevents a wrong tool from being loaded into the machine.

- TMAC: During cutting, the adaptive tool monitoring system, TMAC, optimizes the cutting by measuring tool wear and detecting breakage in real time, while simultaneously monitoring tool and spindle vibration. Using the live cutting data, adaptive control will adjust feed rates in real time to reduce cycle time up to 60%.

- MiConnect Technology: Caron Engineering’s latest innovation, by way of its flowchart style programming, will control the interaction between the CNC control, a Universal Robot and a Sylvac Scan25 vision gauge.

Caron Engineering’s products are unique in the fact they can interface with nearly any CNC machine tool on the market, be customized for almost any application, and its high precision sensors are infinitely scalable to accommodate all types of cutting.

Booth E-135736

Full Range of Metrology and Automated Wireless Data Collection Solutions

The L.S. Starrett Co. (Athol, MA), a leading global manufacturer of precision measuring tools and gages, metrology systems and more, will be demonstrating the latest in quality control inspection technology in Booth E-135044. Supporting Industry 4.0, IoT and the Digital Factory, attendees can see for the first time at a live major event, demonstrations of automated wireless measurement data capture and transmission from handheld wireless/electronic gages via the new DataSure® 4.0 Wireless Data Collection System, or from vision systems and optical comparators via integrated software.

Among the wide range of Starrett solutions highlighted at the show will be the latest optical comparators, multi-sensor vision systems and video-based inspection and measurement systems, DataSure® 4.0 which substantially increases the accuracy and speed of data collection, and the latest precision wireless/electronic tools and gages.

Metrology Systems Solutions – Among a full range of products and solutions that Starrett will feature is the new customizable AVX, featuring an innovative dual optical system, combining the best features of vision and touch-probe inspection, and designed to measure parts with a diverse range of features, sizes and geometries. Also, the recently enhanced AVR300 Multi-Sensor Vision System, featuring the largest field of view to date for Starrett and ideal for repetitive measurements and automatic comparison to CAD files, will be demonstrated. The industry leader in rugged, accurate and reliable optical comparators, Starrett will highlight its latest benchtop models with new MetLogix Mx200 Digital Readouts, which combine an intuitive user experience with current touchscreen conventions and a wide range of functionality.

Precision Tool Gaging Solutions – Starrett will display a broad range of wireless, electronic and mechanical precision measuring tools, and will be debuting its new, enhanced highly accurate, full-featured 2900 Series Digital Indicators, which are now available in wireless models, rechargeable battery and a new 4″ range. Models feature true absolute sensor technology that minimizes data loss, glass scales, +/- .00005″ accuracy and IP67 protection.

Measurement Standards, Custom Gaging and More – The Starrett Tru-Stone engineered granite metrology bases feature the new Superior Red air bearing/solid machine foundation base, gage blocks, surface roughness testers and special gaging capabilities. Attendees are invited to bring their gaging and metrology challenges to the booth where engineers can provide technical support.

Booth E-135044

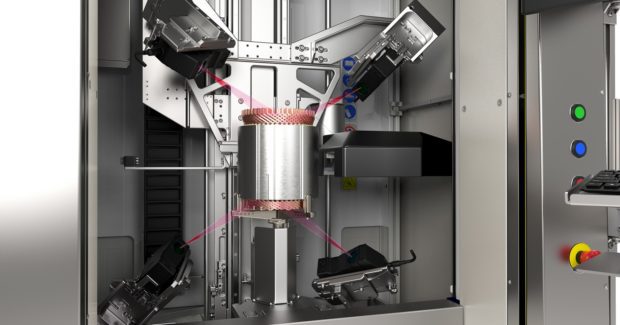

OptoCloud EDU Provides Very Fast Inspection of EV Components

In Booth E-135621, Marposs Corp. (Auburn Hills, MI) will demonstrate OptoCloud EDU (Electric Drive Unit), its latest generation of 3D precision inspection solutions designed for the electrical vehicle industry. Using multiple laser heads in tandem with contact sensors for measurement and vision inspection, OptoCloud EDU reconstructs the 3D model of complex and articulated workpieces in less than a minute to ensure accuracy of the produced component. For example, it can validate 240 electrical contacts of a motor stator in only 30 seconds, which is 100 times faster than a traditional contact system.

The laser heads are integrated over a moving axis designed to position the lasers for the 3D acquisition.

To generate a point cloud of the workpiece, the part is quickly rotated 360° while the different laser heads each acquire spatial data that is then combined into a single 3D reconstruction and graphical representation made possible through the software. The system then executes the requested measurement and vision inspection tasks. Line operators can easily review images and navigate to the desired level of detail to identify any anomalies.

In addition to quality control capability, the multiple laser heads create a point cloud with such a high level of spatial resolution that the details provide a reliable dataset that can also be used for design reviews and final project validation.

Part handling is fast and easy with the OptoCloud EDU. Its design features a Z-axis that allows the laser heads to automatically move out of the handling area, leaving a large space for workpiece handling and removing risk of sensor damage due to handling error.

Marposs OptoCloud EDU can handle components up to 300 mm x 300 mm (12” x 12”) and weights of 60 kg (132 lbs.). The system measures 1200 mm x 1304 mm x 2304 mm (47” wide x 51” deep x 91” tall).

Booth E-135621

Fixture Systems Make Production Faster Than Ever

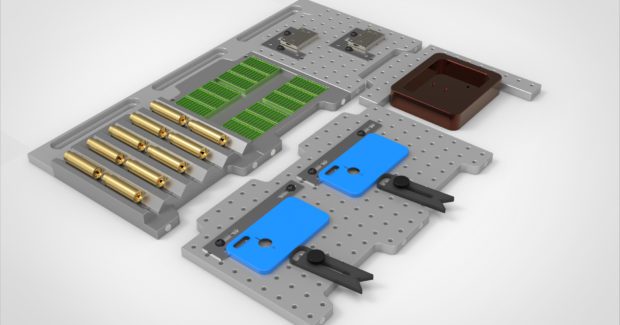

In Booth E-135408, Phillips Precision, Inc. (Boylston, MA), will showcase its products and services that provide improvements across many areas of the manufacturing industry, which includes breaking bottlenecks in inspection and laser marking as well as relieving the complexity and cost commonly associated with valuable inspection data. Fixture up with Inspection Arsenal® and Laser Arsenal® Loc-N-Load™ fixture system and make production faster than ever before.

Inspection Arsenal – From the spindle to the shipping dock, the ability to get inspection data back to the shop floor quickly and accurately, improves the entire production pipeline — and your profits. Quality inspection no longer needs to be complex, costly and time consuming. Modular fixturing reduces downtime, running at risk and overproduction.

Laser Arsenal – The same unique design of Loc-N-Load provides the only dedicated, modular fixture system for laser marking and welding processes. Operators can quickly and easily fixture parts in V-groove or pocketed trays or create custom and semi-custom setups on standard plates using a variety of workholding components.

Booth E-135408

Subscribe to learn the latest in manufacturing.