IMTS 2022: Machine Components/Cleaning/Environmental

Exhibits feature the parts to service and monitor your machines, as well as components for safe and environmentally responsible operations.

Posted: July 20, 2022

Modular Fixturing Solutions Deliver Results

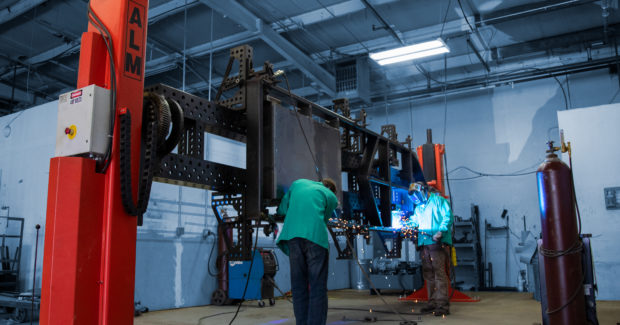

Bluco® Corp. (Naperville, IL), designers and manufacturers of modular workholding solutions, will give IMTS visitors a look at the real-world results being achieved by current Bluco customers, and a roadmap to unlocking similar benefits for themselves.

The Bluco booth, N-236557, will feature stories, case studies, photos and testimonials that show how Bluco modular fixturing systems help deliver shorter production times, better final part quality, and reduced manufacturing costs. In addition, Bluco’s application engineers will be on hand to chat with visitors about the end-to-end welding, positioning and robotics solutions Bluco is best known for.

Modular Fixturing Solutions for Welding – For visitors wondering what separates a workbench from a modular fixturing solution, Bluco’s booth is the place to find answers. Learn how customization and manufacturing expertise combine to create full systems that go well beyond what simple welding tables offer. Among the success stories highlighted in the booth will be:

- Parts finished 28 days faster

- Production doubled, 1/16” tolerance maintained

- Process changed to shave 50% off construction time

Modular Fixturing Solutions for Positioning – Booth visitors will learn how integrating application engineers combine best-in-class positioning technology with Bluco’s modular tooling to greatly enhance safety and comfort while positively impacting overall operations, to achieve results like these:

- 10% cost reduction

- 7x greater accuracy

- Bid won due to modular speed and flexibility

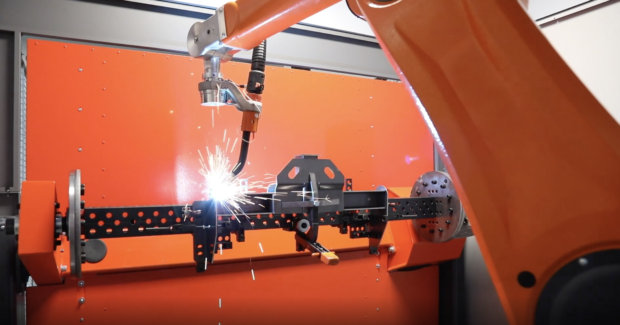

Modular Fixturing Solutions for Robotics – Manufacturers who implemented robotic automation but didn’t get the bump in efficiency and precision they expected, will find out how Bluco modular workholding solutions can often be the missing piece. Application engineers will share how they helped to deliver:

- ROI too high to calculate

- Sluggish automation brought up to speed

- 32 setups from one solution

Bluco will also showcase its modular fixturing solutions for machining in Booth W-432187.

Booth N-236557

Discover the World of Cleaning Solutions with KYZEN

KYZEN Corp. (Nashville, TN), the global leader in innovative environmentally friendly cleaning chemistries, will be in Booth E-121147 to provide the answers to all your manufacturing cleaning challenges. From nuts and bolts to diesel engines, name your process and KYZEN can match the parts cleaning chemistry that will get you the results you need.

KYZEN’s experts will also be present at the Parts Cleaning Conference on September 13, sharing their knowledge about the following topics:

- 3:15-3:45 p.m.: “3D Cleaning – The Future of Part Manufacturing Is Here” presented by Scott Cain, KYZEN’s Western Regional Manager. This presentation will provide a look into the 3D industry and the processes that are being used for cleaning.

- 11-11:30 a.m.: “On-Site Solvent Recycling to Kapture the Savings” presented by Eric Bromley, KYZEN’s Northeastern Regional Manager. This presentation will discuss the importance of maintaining a cleaner fluid to ensure consistently clean parts through recycling the solvents directly from the process chamber.

To keep up with all the latest news regarding KYZEN at IMTS/Parts Cleaning Conference and more, visit www.kyzen.com/about-kyzen/events/. Since its founding in 1990, KYZEN’s innovative cleaning technologies, scientific expertise, and customer support have been repeatedly recognized with the industry’s most prestigious awards.

Booth E-121147

Explore Plug and Play Ultrasonic Parts Cleaning Systems

Take parts cleaning to the next flexible level with Plug and Play systems from Miraclean® Ultrasonics (Ashville, NY) and explore a five-station automated Plug and Play on the floor at Booth E-121015.

Plug and Play systems consist of a series of individual ultrasonic or static tanks in a size appropriate for your cleaning needs that can be organized within a stainless-steel frame. Add, subtract or modify the Plug and Play as your process needs change — these systems are designed to grow with you.

Systems are available with a centralized feed and drain header or chemistry-appropriate drain, and with PLC controlled automation, which advances process loads and controls process actions. Chemistry dosing, rinse quality control, and HEPA filtration are also available, as are other options to meet particular cleaning requirements and throughput goals.

Booth E-121015

Subscribe to learn the latest in manufacturing.