IMTS 2022: Metal Removal

Exhibitors will showcase advances in metal cutting equipment, machining centers, turning centers, drilling, boring, milling, EDM and much more.

Posted: July 20, 2022

Fastems LLC (West Chester, OH) will showcase its CNC automation solutions for milling and turning machines at Booth S-339186. The highlight of the booth will be the world premiere of Flexible Pallet Tower FPT, a compact automation solution for APC and no-APC 4-axis and 5-axis machining centers with 300-to-630 mm pallets. FPT accommodates up to 24 pallets in 113 square feet and its configurable storage allows for different pallet heights, helping to increase machine tool utilization and lights-out production capacity. FPT – like all Fastems automation systems – can be integrated with more than 90 different machine tool brands.

Fastems will also debut the newest version of Manufacturing Management Software (MMS). MMS Version 8 plans, runs and monitors all Fastems automation systems and integrates with various other software and devices to enable flexible and cost optimized production for any batch size. The highlight of MMS Version 8 is the new Insights module that gathers and digests production data and turns it to practical productivity-enhancing tips related to machine, tool and fixture usage. It also offers an easy single-view user interface with drag-and-drop production orders for one-machine pallet systems, EasyRoute feature for introducing new workpieces into production in under 60 seconds, and an automatic Order Generator for recurring orders or maintaining a certain stock level.

Fastems offers a variety of robotic solutions not only for machine tending but to handle other value-adding processes in manufacturing, such as measuring, tool management — even finishing and deburring — which can be done with Fastems’ new modular Robotic Finishing Cell. These solutions are often used together with Fastems flexible manufacturing systems to achieve consistently high quality and lower unit cost.

To improve the customer value of the automation solutions, Fastems is launching a new myFastems portal providing real-time automation status information, alerts, system and maintenance history as well as easy ways to contact support. The portal also provides odometry and usage analyses for service interval optimization, and a spare part and maintenance order tool.

On Wednesday, Sept. 14 attend “CNC Machining Automation – Best Practices for Flexibility, Resilience, and Profitability,” presented by Fastems USA President Nathan Turner, which will be held at 10 a.m. in Room W193-A. He will discuss field-proven ways to produce small, high-mix batches economically by combining the efficiencies of physical movement, process integration, production planning, and employee engagement.

Booth S-339186

GF Machining Solutions Spotlights Precision and Productivity

In Booth S-338329, GF Machining Solutions (Lincolnshire, IL) will highlight advances in EDM technology, service, support, automation and tooling designed to help shops power through their unique manufacturing challenges with complete solutions and holistic support. Additionally, in Booth S-338376, System 3R USA Inc. will highlight tooling solutions to reduce setup time and automation solutions to maximize machining hours.

For customer growth and success, these integrated problem-solving solutions include the new CUT X 500 and CUT P 350 Pro wire cutting EDM machines for precision part generation. To maximize machine-tool value and competitive readiness, the company’s new Success Packs feature comprehensive customer support as well as digital services that add connectivity for remote machine monitoring and troubleshooting from GF Machining Solutions experts. The packs offer subscription-based access to service at four levels designed to maximize uptime and return on investment. Within the packs, rConnect digital services enable manufacturers to monitor machine performance from anywhere via any mobile device through a secure modern platform that also enables GF Machining Solutions experts to provide live remote troubleshooting and support.

Rounding out the lineup of live demonstrations will be an automated cell featuring a MILL 400 U and FORM P 350 with a FANUC Robot. There will also be a System 3R WorkPartner 1+ modular pallet system connected to a GF Machining Solutions LASER P 400 U laser texturing machine.

With Intelligent Power Generator (IPG) technology, the CUT P 350 Pro delivers surface finishes as smooth as Ra 0.08 µm and heightens accuracy with integrated thermal regulation that maintains temperature at ± 0.2°C. To accommodate heavy workpieces, the machine’s QUADRAX® mechanical system keeps the table, work tank and dielectric liquid stable.

Capitalizing on more than a century of EDM technology, the CUT P 350 Pro and CUT X 500’s new Uniqua human/machine interface (HMI) delivers optimal functionality and ergonomics in a 19″ vertical touchscreen, full keyboard and mouse. Abundant automation options add to the machine’s scalable flexibility, with optimized production for electronics, automotive, medical and mold and die manufacturers through more than 600 pre-programmed cutting processes.

The AgieCharmilles CUT X series holds extreme accuracies in machining positioning and pitch. Developed to provide high precision and thermal stability in large runs of complex components, including stamping tools, multi-cavity molds and micro components, the CUT X 500 and all other CUT X machines feature adapted mechanical structures, dedicated machine calibration and testing to deliver pitch accuracy as low as 1.0 µm. High-precision axes, short measurement loops, dual measurement on all axes, consistent isolation of the EDM area from heat sources and submerged working areas optimize conditions for micro applications. Two-spool Automatic Wire Changer technology and an onboard Job Management System help further reduce processing time and simplify job prioritization.

From System 3R, GF Machining Solutions’ source for can-do tooling, automation and software solutions, the WorkPartner 1+ (WPT 1+) scalable modular automation system maximizes magazine capacity for loading and unloading parts and electrodes, while conserving valuable shop floor space. With flexible one, two or three-magazine capacities and fully integrated pneumatic control for gripping devices and table chucks, the WPT 1+ easily serves one or two machines. At IMTS, the WPT 1+ will be spotlighted in in booths S-338329 and S-338376.

Booth S-338376

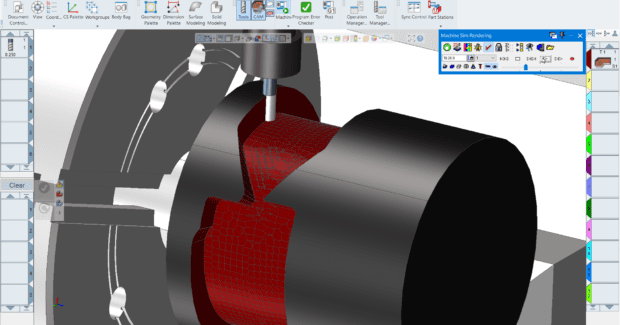

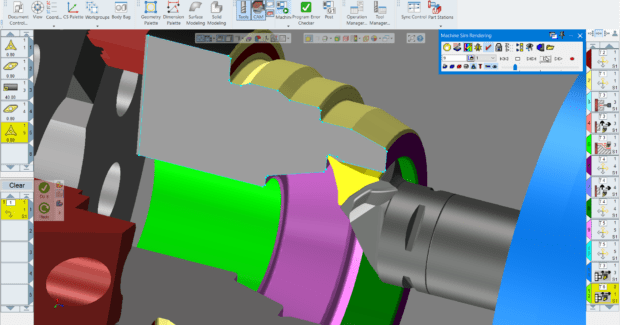

GibbsCAM to Showcase GibbsCAM 2023’s Newest Features

GibbsCAM (Cincinnati, OH) will showcase its latest Simply Powerful CAM software at IMTS. GibbsCAM’s product experts will be in Booth S-338880 to explain powerful new features of version 2023, which will be released just weeks after the show.

GibbsCAM Vice President Nick Spurrett asserted: “We are truly excited to showcase our latest GibbsCAM release. It is packed with features and receiving really positive reviews from customers.”

Cylindrical milling in GibbsCAM 2023 is easier with direct selection of a “slice” in the CS depth axis — select a closed profile to machine a cylindrical boss or pocket or select two loops to machine a groove or ring. New Spiral Boring cuts a spiral out to the full diameter at each Z step, which increases cutting feed rate and depth due to a more consistent tool load.

PrimeTurningTM high performance turning strategy for Sandvik Coromant, and CoroTurn Prime Type A and Type B inserts allows optimum feed rate adjustment for gentle and accurate cutting in either direction. A new tool type, Multifunction Insert Drill, has been added as a periphery insert that can seamlessly switch between turning, lathe drilling, and mill drilling without retraction or tool change motions.

GibbsCAM GO Turning can now specify Rake and Back Relief for tool inserts to more accurately define the 3D geometry of the tool inserts. A new option for Lathe Drilling with counter-rotating tools commands the live tooling spindle to turn in the opposite direction at a specified RPM to increase spindle speed and material removal rates.

The Elliptical Contour process may now be used with elliptical bores inside of solid parts. Thread Turning operations are expanded with Face Threading, Variable Pitch Threading, Multi-pitch, and Position Tool Front options.

Organizing parts is easier than ever to match the way you work. The ability to earmark parts by work group or coordinate system, create operation groups, and specify active and inactive operations, helps users to track part information throughout the CAM process.

GibbsCAM will exhibit alongside Cimatron in Booth S-338880 as key partners in the Sandvik Design and Planning Automation Division. “Sandvik’s investment in this business segment represents a commitment toward a greater total solution for manufacturers,” Spurrett stated.

GibbsCAM software programs, simulates, and controls any CNC machine — from 2D to 5-axis milling, turning, multitask machining, and wire EDM. Additionally, GibbsCAM in-process probing reduces handling for total accuracy, and a comprehensive CNC solution.

Booth S-338880

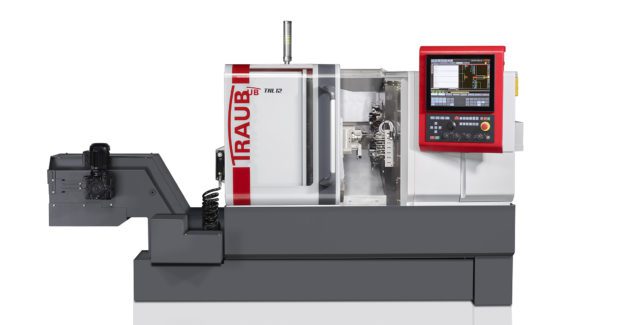

Three Machines to Make North American Debut at IMTS

At IMTS, INDEX (Noblesville, IN) will host the North American debut of its next generations of its G220 turn mill center, MS32-6 CNC multi-spindle and TNL12 sliding headstock lathe. The company will also present information on the latest additions to its iX4.0 Industry 4.0 platform that monitors machine performance, as well as provide space for the demonstration of a metal 3D printer by its subsidiary, One Click Metal. INDEX will be in Booth S-339119.

The G220 incorporates and refines the design principles introduced via the larger G320, G420 and G520 machines. With twin spindles, dual tool turrets, a 5-axis milling spindle and high-capacity tool magazine, the machine produces a variety of parts in a single setup.

The G220’s milling spindle offers a hydrodynamically mounted Y/B axis arranged above the axis of rotation. Each of the machine’s turrets provides movement along the X, Y and Z axes and each of the turrets’ stations can be equipped with live tooling.

The MS32-6 CNC multi-spindle features a modular design that achieves flexibility and fast, user-friendly setups, bringing the benefits to a broader range of applications. Accommodating up to 32-mm bar stock, the MS32-6 easily handles a variety of complex parts as the machine is equipped with two V-shaped cross slides at each spindle position. Each cross slide offers X and Z axes as standard; C and Y axes, together with live tools, can also be implemented to allow for a broad range of machining processes, including off-center drilling, threading, contouring, hobbing and polygonal turning. Each of the machines’ slides can also be alternatively configured with a single NC axis for grooving or drilling.

Each cross slide in the MS32-6 now incorporates INDEX’s patented W-serration locating system that provides μm-accurate alignment of the tool holder. Coupled with the company’s newly developed quick clamping device, tools can be setup off the machine and then quickly installed, reducing tool change times by 50%. Additionally, the machine incorporates the same W-serration system on its live units for drilling, milling and polygonal turning. By presetting tooling for these operations off the machine, setup times can be reduced by up to 92%.

Comprehensively redesigned from its previous iteration, the TNL12 sliding headstock lathe offers an exceptional value proposition to manufacturers of small parts. Like its predecessor, the TNL12 features four tool carriers that can be applied to a workpiece simultaneously, albeit with significant changes to the machine’s kinematics. While the front-working attachment and counter spindle were previously arranged on a single slide, they are now housed on separate slides, which allows for greater flexibility in programming.

The features enabling rear-end machining also have undergone substantial changes. While the former model of the machine offered X-axis machining on the counter spindle, the TNL12 provides full 3-axis machining in this position. A new back-working attachment offers six tool stations, with up to four allowing live tooling, as well as a flushing unit.

Booth S-339119

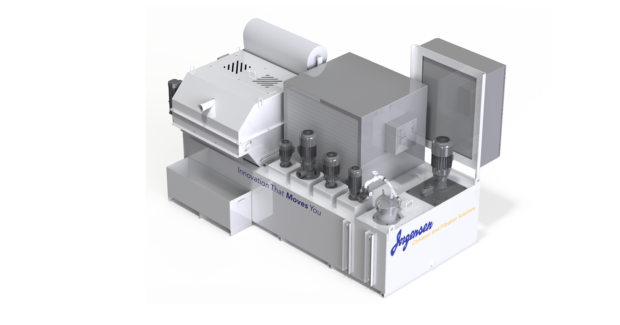

Jorgensen to Highlight New Machining Filtration Line at IMTS

Jorgensen Conveyor and Filtration Solutions (Mequon, WI) will spotlight its new FlexFiltration line, including the company’s new Flex G Series of modular filtration systems, in Booth S-338164. The cost-effective systems feature pre-engineered modules that ensure fast, easy, flexible filtration configurations and add value for virtually any application.

FlexFiltration systems efficiently remove fine chips and grinding sludge to achieve coolant clarity down to 10 microns or less. They are especially well suited for challenging applications with materials that range from cast iron, steel and aluminum to composites and plastics.

Pre-engineered base configurations and numerous options enable quick construction of FlexFiltration systems to meet specific coolant-flow requirements. Standard, low-profile and stainless-steel tanks make these systems ideal for machine tool OEMs and regular end users. Other modular options that complete a system include high-pressure pumps, auxiliary pumps, tramp oil skimmers, coolant chillers, heat exchangers, liquid level sensors, temperature sensors and the ability to control/interface with existing pumps and other equipment.

Jorgensen’s Flex G Series systems feature gravity media filters. The gravity media filtration option is the first one available in the FlexFiltration product line. Gravity filters are offered in 30, 60 and 90 gpm options and come standard with low media roll detection, no media alarm sensor and automatic roll advance. A variety of different disposable cloth medias are also available based on specific applications. Additional primary filtration options including bag filtration, cyclonic, and permanent media types will soon be offered.

With more than 70 years of experience in designing and manufacturing advanced conveyor, coolant filtration and material handling solutions for the machine tool, fluid filtration, metalworking, unit handling and recycling industries, Jorgensen Conveyor & Filtration Solutions offers a wide range of standard and customized systems to companies across North America and globally.

Booth S-338164

MC Machinery to Showcase Latest EDM and Precision Milling Technology

MC Machinery Systems (Elk Grove, IL), a subsidiary of the Mitsubishi Corp., is a premier supplier and servicer of fabrication and milling equipment, including Mitsubishi lasers, EDMs and automation systems. The company will be in Booth S-338129. MC Machinery’s featured machines at IMTS will include:

New Sinker EDMs-With artificial intelligence (AI) adaptive control technology, the new Mitsubishi SV12P and SG12 sinker EDMs optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time. The proprietary AI technology makes logical use of condition-monitoring data. For example, these new machines can diagnose real-time problems within the burn and directly modify specific parameters for a stable and accurate output. This allows machine operators of all experience levels to produce quality results in complex cavities and shapes. Because the AI technology analyzes current sensor data to determine optimal conditions, it reduces overall electrode wear and costs. By monitoring these parameters, the machine operates more efficiently and can more accurately predict machining times. The SV12P will be outfitted with Erowa Robot Compact 80 milling and sinker automation.

The Gantry EAGLE 800 sinker EDM is best in class for large-part and molding applications, featuring low electrode wear and fast cycle times. Combining the latest in technological innovation with a unique human-centric design, the Gantry Eagle series has on-board components designed to reduce wear and tear, which in turn decreases maintenance and costly downtime. The Gantry Eagle 800 has a large, easy-to-access working area that requires less floor space than other sinker EDM models.

Wire EDMs-The MV1200-R Mitsubishi wire EDM features the latest machine construction, submerged threading, fiber optic machine communication and power supply technology. As MC Machinery’s best-selling wire EDM, the MV-R series is known to be dependable and easy to use, spurring increased productivity and efficiency.

The MV2400-R Mitsubishi wire EDM is the perfect solution for a wide range of applications, featuring a larger tank capacity and low operational costs. The innovative MV-R series features improvements in machine construction, auto threading, internal machine communication and power supply technology. It also highlights Mitsubishi’s dedication to high precision, with innovations including the highly reliable non-contact cylindrical drive system on the X, Y, U, and V axis drives.

The MV4800-S Mitsubishi wire EDM is ideal for large part applications up to 20-inches high (standard), and 32-inches high (optional) and can perform submerged cutting up to 20-inches deep. With an annealing length of more than 27 inches, this system is capable of threading through the workpiece both at the start point and through the gap.

The MX600 Oil Advance Plus wire EDM combines the ultimate in machine accuracy and surface finish, with wire capability down to .0008″ (.02mm) Dia. The MX600 features a Nano-pulse power supply and DMX-S Super Digital Control sensor, specifically shaping each spark producing surface finishes down to 1.6µ “Ra. This machine provides the perfect opportunity to advance micro-machining capabilities.

Precision Milling-The Roku HC658II is the gold standard for hard milling and electrode manufacturing. This machine is a full-bridge style design for supreme accuracy and each way surface is meticulously hand scraped. The highly dependable 32,000 rpm spindle, combined with the best graphite protection in the industry, makes the Roku HC658II the perfect solution for high-precision manufacturing and mold industry customers.

The ANDROID II linear drive milling machine is a machining center designed from the ground up for extremely precise, hard steel and carbide machining with accuracies within ±1µm. With a 60,000-rpm spindle, it boosts productivity on high-precision jobs, simultaneously delivering accuracy, quality, precision and speed.

The Ingersoll Eagle V550 graphite machining center has an innovative compact design and features high-speed, high-precision 5-axis machining for small graphite electrodes and mold/die components.

Booth S-338129

Five-axis and Vertical Machining Centers Offer High Precision and Accuracy

Mitsui Seiki (Franklin Lakes, NJ) will highlight the PJ303X 5-axis machining center and its popular PJ812 vertical machining center at Booth S-338700. The PJ303X 5-axis provides maximum precision and versatility in processing of smaller workpieces up to 230 mm tall and 280 mm in diameter (9″ x 11″), and 20 kg (44 lbs.) in weight. Typical applications cover an extensive range of critical parts such as lens molds, medical products, EDM electrodes and fuel cell components.

Its X-, Y-, and Z-axis travels are 300 mm, 325 mm, and 200 mm (11.8″, 12.8″, 7.9″) respectively. A-axis rotation is +40˚ to -100˚, and the C-axis rotates a full 360˚. High-speed linear motors move the X-, Y- and Z-axes, while the rotary axes employ direct-drive motors. Rapid traverse speed for the X-, Y-, and Z-axes is 20 m/min (66 ft/min).

A 50,000-rpm, HSK-E25 taper spindle offers high-speed machining capability. An automatic tool changer engineered to store up to 24 tools as large as 40 mm (1.57″) in diameter and 100 mm (3.9”) in length provides tooling versatility.

The “J” in the PJ812 represents “jig,” which is ideal to machine critical medical, optical, electric vehicle, mold and die, and aerospace parts. The model at the show will be equipped with a Renishaw spindle probe and a Dynavision system.

The PJ812 offers X-1200 mm, Y-800 mm, Z-500 mm. Max work size is 1200 mm x 800 mm x 450 mm. Table load accommodates 1,500 kg. The VMC provides positioning accuracy and repeatability of +/- 1µm. A thermal compensation system employs sensors on the machine faceplate and inside the spindle to minimize the effects of temperature changes on part accuracy and cut temperature-generated displacement by 60 percent. This system also reduces Z-axis thermal growth and deflection by 30 percent. Cooling systems for slide way lubrication and ball screw cores stabilize axis feed precision.

This ultra-precision machine allows for more complete machining of precision components including precision boring, milling, drilling and tapping. Machining center technology and jig borer precision in one machine. The machine features a full enclosure and various coolant system options. The model at the show will have a 690-liter cooling tank, a 40-tool ATC, and the advanced FANUC F31i-B5 control with the i-H Pro panel.

Booth S-338700

Large Diameter BTA Drilling Machine with 3-Axis Capability

The TechniDrill TBTA-3A-6 is a deep-hole drilling machine using the BTA process (Boring & Trepanning Association). The TechniDrill deep-hole drilling machines are designed and manufactured by Kays Engineering (Marshall, MO). The company will be in Booth S-338373. The TBTA-3A-6 can drill a 6-inch diameter hole from solid in a single pass and has 3-axis capability. The machine has applications in the aerospace, mold, and oil and gas industries.

The machine has 6 inches (152 mm) of BTA drilling capacity and 48 inches (1,219 mm) of drilling depth. The worktable moves horizontally back and forth to provide the X-axis travel, and the drill slide moves vertically on a column to provide Y-axis travel. The spindle motor is available with up to 75 hp. The high-pressure coolant system is rated at 200 gallons/minute of coolant flow and 1,500 psi of coolant pressure.

Booth S-338373

UNISIG to Spotlight Gundrilling Flexibility for Medical Applications

In Booth S-339159, UNISIG Deep Hole Drilling Systems (Menomonee Falls, WI) will showcase the technologies that make it an industry leader in extreme depth-to-diameter hole drilling, including the ability to create holes with outstanding precision. The company’s UNE6 Series small-diameter gundrilling machines excel at drilling deep holes in demanding materials, including high-strength titanium and surgical-grade stainless steel, and achieve superior concentricity through tool and workpiece counter rotation.

At the show, UNISIG will highlight medical production on the UNE6-2i that features two independent high-speed spindles for production of 10″ or 30″ maximum part lengths and available integrated automation onboard. The machine’s high accuracy allows it to drill hole diameters from 0.03-0.25″ (0.8 mm-6 mm) and depth-to-diameter ratios from 20:1 to more than 100:1 in workpieces up to 11 lbs. (5 kg). With 28,000 rpm total drilling speed and a 3,000 psi (207 bar) flow-based coolant system, the UNE6-2i combines exceptional process control with an intuitive smart control interface.

Customers in industries that include aerospace, automotive, energy, firearms, hydraulics, defense, and oil and gas, as well as medical and moldmaking, can consult with application engineers and technical sales staff at IMTS to discuss optimization of applications including drilling and beyond.

A world leader in the manufacture of deep-hole drilling systems, UNISIG provides comprehensive machine, tooling and automation solutions for customers around the world from its state-of-the-art production facility and headquarters in Menomonee Falls, Wis.

S-339159

Subscribe to learn the latest in manufacturing.