IMTS 2022: Fabricating and Lasers

Exhibitors will highlight innovations in fabricating, laser and waterjet-based machining, as well as welding, metal treating and marking equipment.

Posted: July 20, 2022

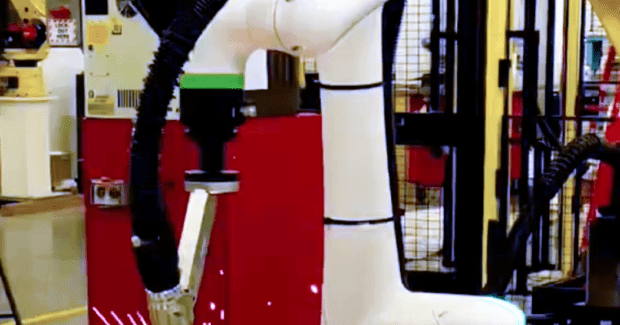

New Welding Cobot, the FastARC CX1000, Alleviates Labor Challenges

Skilled welders are hard to find, so it’s best to assign them to higher return jobs instead of using them for simpler welding tasks. Fabricators and job shops can now give the easy, low-value weld jobs to the new FastARC® CX1000 collaborative robot (cobot) from Acieta (Waukesha, WI). The company will be in Booth N-236270.

“The FastARC CX1000 repeatedly welds accurate and high-quality welds all day, every day,” says Bill Brauer, senior robotic systems engineer at Acieta. “That means less scrap, increased uptime and greater capacity, so shops can take on more work.”

The FastARC CX1000 cobot is cart-mounted and can be moved around the shop wherever it’s needed. Changeover is quick, making the FastARC CX1000 perfect for low-volume, high-mix shops. Hand-guiding the robot makes for simple programming so no advanced programming experience is necessary. An intuitive interface features drag and drop programming.

As a standard, pre-engineered system, the FastARC CX1000 can be available for delivery and installation within just weeks. With many end-of-arm tooling options, the FastARC CX1000 can be uncoupled from the weld cart and repurposed for different applications like machine tending or sanding when not welding.

The FastARC CX1000 cobot is equipped with a FANUC 6-axis, 10 kg capacity collaborative robotic arm that’s maintenance free for up to eight years. The system is compatible with Lincoln Electric® and Miller® welders and is IP67 rated with sealed components to work in industrial environments.

A leader in the robotics industry for nearly 40 years, Acieta provides a wide range of robotically automated solutions and services for the manufacturing industry. With locations in Waukesha, Wis., and Council Bluffs, Iowa, Acieta has integrated more than 5,500 automation systems for customers throughout North America. Acieta is a leading FANUC Authorized System Integrator and member of the RIA Certified Integrator group.

Booth N-236270

Industrial Fiber Laser Solutions for Marking and Traceability

Dapra Marking Solutions (Bloomfield, CT) will showcase the latest industrial-grade fiber laser marking and engraving technology, which provides reliable performance, fast cycle times, and outstanding flexibility to fit any manufacturing environment – from standalone workstations to production line integration. Dapra Marking Solutions will be in Booth N-236246.

Datamark FL Series laser markers from Dapra Marking Solutions offer precise, repeatable, non-contact marking of metals, alloys, and most plastics. Available with Q-switched and MOPA fiber laser sources from 20-to-50 watts, these systems are capable of everything from high-contrast annealed heat marks with no surface disruption to the crisp engraving of both basic text and complex patterns at depths exceeding .004”.

FL Series markers can be mounted in open Class 4 workstations or Class 1 safety enclosures, with a programmable Z-axis, optional rotary D-axis, and integrated barcode reading and verifying technology. They are designed for easy integration into robotic cells, production lines, and other highly engineered solutions to support modern manufacturing environments.

Every system ships with the Datasoft Pro Windows software suite, supporting easy logo import, serialization, date coding, Data Matrix and QR codes, UID and UDI syntax, and much more. With an icon-based, WYSIWYG interface, the software puts all the tools to meet your most challenging marking requirements at your fingertips.

For nearly 40 years, Dapra has supported manufacturers throughout North America in meeting their unique marking and traceability requirements.

Booth N-236246

Innovative Hydraulic Press Solutions Include Automation and Custom Applications

Greenerd Press & Machine Company (Nashua, NH) will highlight the company’s extensive hydraulic press and automation capabilities in Booth N-236402. Application experts and design engineers from Greenerd will be available to discuss specific user applications and press requirements.

Greenerd offers unique hydraulic press application solutions for a range of industries. One example that demonstrates this versatility is a large 2500 Ton Compression Molding Press that Greenerd will discuss at IMTS. Greenerd has designed and engineered this 2,500-ton press and is building it in its main facility as part of a seven-press order involving precisely controlled heated platens measuring 108″ square. The press features an innovative mold transfer system which significantly improves the ergonomic and safety dynamics for operators and reduces the press idle time between cycles.

“To meet the demands of today’s challenging applications we are providing manufacturers with press solutions that are flexible, productive and reliable as well as often being quite large and complex,” commented Greenerd Press & Machine Co.’s CEO Jerry Letendre. “For even greater manufacturing efficiency, we are able to provide our hydraulic press customers with turnkey, state-of-the-art robotic and other product handling solutions.”

Greenerd is a Tier 1 Industrial Authorized Robot System Integrator of FANUC, the industry’s leader in automated manufacturing equipment. The partnership gives Greenerd full access to the comprehensive offerings of FANUC’s robots including all models, training and support, providing state-of-the-art automation solutions in short time frames.

Complete, fully integrated production systems can be provided including simple raw material feeding systems, and robotic solutions including loading/unloading the press, the ability to perform an optional secondary part manipulation or process, automated inspection of parts, and stacking finished products for downstream processes. The scope of automation can also encompass part inspection systems, ranging from small sensors to complex camera inspections, and temperature monitoring/control of press and non-press related systems. Streaming critical production data to and from the press is also offered.

Greenerd’s extensive line of hydraulic presses are available in a variety of styles ranging from gap frame and straight-side to die-spotting and forging presses, with unlimited size and tonnage capabilities. Greenerd has a long tradition of designing, engineering and manufacturing customized hydraulic presses with product handling solutions. Designed to meet challenging application needs, Greenerd presses are made to withstand the rigors of around-the-clock production and deliver many decades of service.

Booth N-236402

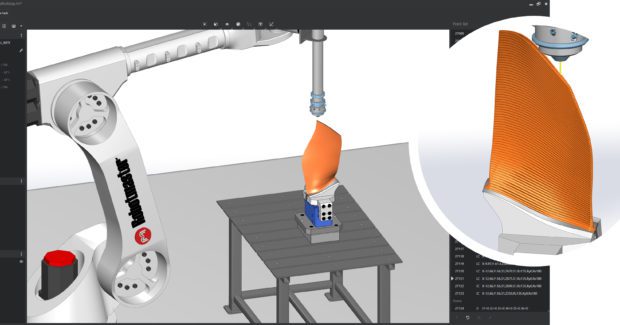

Cutting Systems and Software Streamline Precision Machining Operations

Hypertherm Associates (formerly Hypertherm) a Hanover, N.H.-based manufacturer of industrial cutting systems and software, will showcase OMAX waterjet products from Booth N-236222. Products on display will include the all new OptiMAX, a new generation of waterjet providing faster and more accurate print to part cutting, while reducing downtime. Attendees visiting the booth can see how OMAX waterjet systems make it easy for anyone to create high-precision, complex 3D parts while enjoying live demonstrations and special show promotions.

Just across the aisle in Booth N-236311, Hypertherm Associates’ Robotmaster team will demonstrate the latest version of its offline programming software for robots. Robotmaster software decreases robot programming time from hours to minutes with an intuitive programming workflow and powerfully integrated CAD/CAM functionality.

“We are excited to return to IMTS following the COVID necessitated cancellation of the 2020 show,” said Kristy Gerwig, who is managing the show for Hypertherm Associates. “We believe show attendees will enjoy seeing the products we’ve introduced during the past two years and gain a better understanding of how our products can help them streamline their precision machining operations.”

Hypertherm plasma and OMAX waterjet cutting products are engineered and manufactured for use by companies around the world to build ships, airplanes, and railcars, construct steel buildings, fabricate heavy equipment and more. Its products include industrial cutting systems, CNCs, and software trusted for performance and reliability that result in increased productivity and profitability for hundreds of thousands of businesses.

Booth N-236222 {Omax}

Booth N-236311 {Robotmaster}

Carbide Application Equipment Prolongs Machine Life

Rocklin Manufacturing Co. (Sioux City, IA) will be exhibiting portable marking and coating solutions to inefficiency at Booth N-236304, which includes the Rocklinizer® Carbide Application Equipment. The Rocklinizer deposits extremely hard tungsten carbide, titanium carbide, and rock-hard electrode material ranging from ~60-80 Rockwell C onto and underneath the surfaces of metals, tools and dies. This low heat hard surfacing process reduces metal-on-metal wear, boosts grip, restores dimensions, and ultimately extends the useful life of machinery to delay or even avoid new equipment purchases.

The newest Rocklinizer deposits a coating ranging from as little as .0001” to .010” and higher onto the base material, all controllable within .0001” by digital machine setting for a precise application. The higher power settings produce a rough surface well suited for gripping applications, specifically tube bending dies, collets, clamps, feed fingers, and even forklifts and non-slip flooring. Medium deposits are best for restoring tolerances on bearings and shafts and for die casters seeking to prevent heat checking, soldering, and seizing of cores. The lower deposits are ideal for preventing slug pull in punching and stamping operations and extending the life of cutting edges and tooling.

As the electrode is deposited over the same area via the rotary applicator, the Rocklinizer is merely filling in gaps but not adding more materials to existing deposits. Only by changing the machine setting or the electrode type is additional wear-resistant material added. This feature results in a truly uniform coating. Unlike welding, no appreciable heat is generated, and the electrode material will not separate or flake off the workpiece. Once the process is completed, no heat treating, grinding, or other surface treatment is necessary.

The Rocklinizer Model 950 offers an extremely fast application speed, a feature that is ideal for coating larger parts and dies. A 5-square inch coating takes about one minute via high-speed settings, while the process can be slowed for more delicate operations. A continuous duty air pump is embedded inside the unit to deliver cooling at higher settings and ensure full portability of the 35-pound unit.

Booth N-236304

TRUMPF Showcases Automated Arc Welding, and 3D Laser Welding and Marking

In Booth N-236217, TRUMPF Inc. (Farmington, CT) will show the latest in automated arc welding, 3D laser welding, and 3D laser marking. TRUMPF will highlight the TruArc Weld 1000, an automated arc welding system designed for easy and affordable high-mix, low-volume production. The company will also showcase laser technology for 3D processing, including the TruLaser Station 7000 fiber, a versatile, compact and fully equipped, low-investment 3D laser welding system, and a TruMarkStation 7000 with a TruMark 6030 marking laser for high-performance 3D laser marking.

The TruArc Weld 1000 makes it easy for fabricators to get started in automated welding. For affordable high-mix, low-volume production, the machine is the perfect solution. A collaborative robot, or “cobot,” makes it easy to program and weld in just minutes. Even first-time operators can program by simply guiding the cobot by hand. Programming is greatly simplified by the operating unit on the welding torch and factory settings for different materials and sheet thicknesses. Thanks to the rapid programming, fabricators have a cost-effective means of tackling short production and single part runs. Overall, the TruArc Weld 1000 creates a process that is more efficient than manual welding and produces a high-quality weld seam.

Cost-effective and versatile 3D laser welding is achieved with the TruLaser Station 7000, a versatile, compact, and fully equipped low-investment 3D laser welding system. The higher power laser enables a broad range of applications. The station facilitates efficient and ergonomic 3D laser welding of small assemblies such as sensors, rotationally symmetrical components and medical devices. The large work area also makes it possible to integrate fixtures and process larger components in a small installation area. Fully integrated image processing ensures reliable weld seam positioning.

TRUMPF will also demonstrate laser marking of 3D metal printed parts with a TruMark Station 7000 laser marking station that features a TruMark 6030 marking laser and VisionLine 3 feature recognition capability. The TruMark 6030 is a high-performance marking laser with 3D functionality. The laser’s outstanding beam quality and high-power densities ensure clean material removal and high contrast

markings. The TruMark 6030 can be integrated into production systems quickly and easily.

Booth N-236217

Compact ArcWorld® RS Workcell Replaces or Supplements Manual Welding

The newest model of Yaskawa Motoman’s (Dayton, OH) ArcWorld family of pre-engineered robotic arc welding workcells, the ArcWorld RS, delivers a highly flexible, compact and cost-effective option for integrating robotics into current weld processes. Ideal for replacing or supplementing manual welding, such as pre-assembly before welding in larger robotic workcells, this solution is designed for optimizing small- to medium-size part production for medium volume fabrication. Yaskawa Motoman will be in Booth N-236601.

Requiring only 2.3 square meters (25 sq. ft.) of floorspace, the ArcWorld RS utilizes a rotating station (RS) design, manually indexed by the operator, featuring two fixture tables with a 100 kg payload capacity per side. This facilitates quick changeover, allowing parts to be safely loaded and unloaded while the opposite station part is welded. Parts up to 425 x 700 x 990 mm can be processed.

The ArcWorld RS features a single high-speed, 6-axis AR900 arc welding robot with YRC1000 controller. An intuitive digital weld interface for all power source brands is included. An integrated weld package includes either a Miller® Auto-Continuum™ 350 or Lincoln Electric Power Wave® R450 power source, wire feeder, wire spool holder and a variety of available torch options. Processes from the power supply are accessed by Yaskawa’s easy-to-use digital Universal Weldcom Interface, giving full control of welding parameters and settings from the robot programming pendant.

This solution offers overhead LED lighting and is enclosed with sheet metal and light-reducing polycarbonate for arc and spatter protection. A built-in extraction hood for fume filtration and four-button operator panel with E-stop also come as standard.

The ArcWorld RS is safeguarded and has a completed risk assessment compliant with ANSI/RIA R15.06-2012, and other relevant ISO and CSA standards. The robot controller’s Functional Safety Unit uses “stand still” monitoring for the robot and safety signals. All workcell doors are safety monitored.

The workstation, including the robot and safety fencing, comes attached on a common base with integrated cable management for easy shipping and installation. Easy open, safety-interlocked side panels allow for easier robot programming and equipment access.

Additional optional features are available, including a light beacon (3 color), Digital TouchSense, gas flow rate meter (CWT) gas flow sensor (SMC) and a torch cleaning station (with or without wire cutter).

Founded in 1989, the Motoman Robotics Division of Yaskawa America, Inc. is a leading robotics company in the Americas. With over 500,000 Motoman robots installed globally, Yaskawa provides automation products and solutions for virtually every industry and robotic application, including arc welding, assembly, coating, dispensing, material handling, material cutting and more.

Booth N-236601

Subscribe to learn the latest in manufacturing.