Embrace Digitization and Automation in the Welding Process

Take your welding operation to the next level by undertaking the first steps toward incorporating the automation journey in your shop.

Posted: July 19, 2022

Automated robotic welding in and of itself suggests a whole new level of welding. While manual welding is still necessary for a bevy of applications, automating the process, while daunting, can save fabricators considerable time and costs, and reallocate the knowledge and skills of an experienced workforce to keep production going when the lack of skilled workers is still high. Taking welding processes to a new level isn’t as complicated as one might imagine and partnering with the right welding technology supplier is key to a successful transition.

The first step in the journey starts with the Welding Procedure Specification (WPS), which is defined by the part manufacturer but can be adapted to fit into different welding systems. A good approach when advising potential customers is to take a customer’s WPS and utilize it in your processes. Don’t try to redefine the existing procedures but work within them to create a usable mechanization/automation system to achieve the same or better results.

The WPS defines heat inputs, weld strength requirements and more. It takes into consideration customer quality needs which can be dependent upon the weight of the structure, material being fused and end use. Heavy structures up the ante and specifications become more particular. For example, weld joints must be stronger than the base material itself so that if there is a part failure it will never be because of the weld joint, it would be the fault of the base material. The WPS is the base upon which the entire system is built.

Next Steps

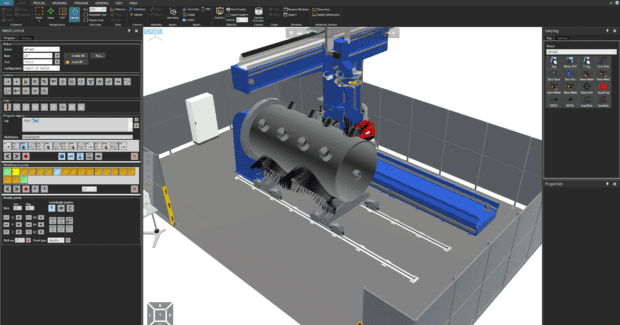

The next step begins with adopting 3D weld part drawings as part of the operation. Automating the welding process is dependent upon this. Pemamek has made the creation of 3D weld part drawings easy on customers with its Pema WeldControl 300 software. Available in three modules – OLP for offline programming, CREATE for entering measurements and features parametrically, and SCAN, which creates the 3D models using data captured via laser scan, WeldControl 300 generates weld paths that self-correct based on the specifications already entered into the system. Once the commitment to digitizing drawings is made, the manufacturer must ascertain what type of cell base should be installed: robotic welding or tubular welding? Then, using the 3D drawings as a guide, a flexible modular production cell tailored toward welding the part is built. This approach is ideal for welders working with one-off and/or large-scale projects such as ships or offshore wind platforms. Another factor to consider when building these large cells is the weld time. Weld time analysis yields a conservative estimate of what the weld time will be in the cell and the resulting time and labor savings by automating the process during a 24-hour/7-day-per-week cycle.

The longer the weld time on the piece, the longer the arc time and the less interaction you need to get a weld done. Before the cell goes into production a Factory Acceptance Test (FAT) is performed using a mock weld piece that mimics the real part to make sure everything runs smoothly and according to the WPS, and that any consumables are in good enough shape to last during the unaccompanied automated welding process. Conversely, it also detects potential problems.

Automation also reduces the dependency on consumables such as flux and/or simple wires because the feeds, speeds and heat input are being controlled simultaneously. Pemamek has thought of that, too, with its WeldControl 100 and 500 panel management systems, which are specially designed to control robotic movement from a workstation located virtually anywhere on the shop floor. With worker safety top of mind, this is just another advantage of adopting an automated system.

Automating the welding process also addresses the big elephant in every shop: the worker shortage. Automation allows shops to use their existing employees and empowers them to learn new skills, if they desire. A digital database supports younger workers regarding operating welding cells. By working within 3D drawings, everything becomes much simpler. With a digital blueprint, all workers can do more.

As with everything that is automated, it takes a leap of faith and investment to do it right. Partnering with a welding solutions expert with many years in the business helps make this daunting process a little easier. Companies realize the financial incentive to automate when they see the reduction in expenses and increase in generating higher-quality products as experienced by their peers.

Each company’s journey to that next level will be uniquely their own but each one that decides to take the first step will need to embrace digitization and automation before lifting the other foot.

Subscribe to learn the latest in manufacturing.