IMTS 2022: Abrasive Machining, Sawing, Finishing

Exhibitors will showcase the latest in grinding technologies, sawing and cutoff machines, as well as a variety of finishing technologies.

Posted: July 19, 2022

AMADA Machinery America, Inc. (Brea, CA) has more than 70 years of industry experience. AMADA Machinery America (formerly known as Amada Machine Tools America) is committed to helping customers deliver dependable service and top-quality work with exceptional grinding and sawing solutions.

While AMADA Machinery America takes great pride in its legacy, it is its drive and commitment to continuous improvement that sets them apart. AMADA Machinery works to achieve the market-leading quality with reliable productivity. Stop by Booth N-237200 to see what its latest and greatest products are.

One of the newest additions to AMADA’s product line is the industry leading Fabricating Marvel Series Vertical Tilt-Frame Saws. The saws feature cutting capacities from 15” x 20” all the way up to 31.25” x 37.5” and mitering up to 60 degrees left and right. The Marvel Series Vertical Tilt-Frame line is backed by more than 110 years of unsurpassed performance and support.

Come see the world’s fastest cutting saw in action. Introducing the HPSAW310. This saw is specifically designed for high-performance cutting. This CNC Hyper Saw redefines high performance cutting with its innovating speed, accuracy, environment and tool features. The HPSAW310 has a zero-twist blade frame, CNC control, a round diameter cutting capacity of 1.97”-to-12.2” and features a 2-5/8” blade.

Along with the band saws, AMADA Machinery will also feature two grinders and a Spartan Ironworker. The SSR-5 is a rotary surface grinder that provides enhanced usability and exceptional efficiency while the enhanced feed axis speed shortens setup time. The Meister G3 UP is a high precision forming grinder, which provides single operation, five-face grinding. This new and improved Meister series is the next level of automated griding. The Spartan Ironworker MSIW60D has five workstations, with LED lighting, and the strongest stripper in the industry.

Stop by Booth N-237200 at the front entrance of the convention center and see why AMADA Machinery’s products outperform the competition. AMADA’s team has shown commitment and improvements in pushing the product lines to become its best version.

Band saws, ironworker, and grinders on display:

- Hyper Saw HPSAW310

- Carbide Circular Saw CMII75DG

- Vertical Tilt-Frame Band Saw VT4555M-Marvel Classic

- Vertical Tilt-Frame Band Saw VT5063SW-Marvel Classic

- Horizontal Post Stye Saw HFA360P

- Ironworker MSIW60D

- Grinder MSG3UP

- Grinder SSR-5

ANCA Showcases Smart Automation for Whole Factory Connectivity

Once again ANCA (Wixom, MI) is on the forefront of innovation with AIMS – ANCA Integrated Manufacturing System. An Industry 4.0 factory wide integration, AIMS is ANCA’s solution for considering the factory as a single machine. Rather than separating workflow into many different elements of design, blank preparation, grinding, laser marking, washing, packing and shipment – AIMS streamlines the entire tool manufacturing process and complementary technologies.

An interactive and fully operating AIMS cell will be on display in Booth N-237406. The demo showcases the main modules of the AIMS system — an AutoSet job preparation station; an AutoLine for pallet and tool transfer; and the AutoFetch, which is a robot responsible for material transfer between processes — pallet and individual tools between job preparation, grinding and tool measurement on ZOLLER measuring machine.

With AIMS, ANCA is responding to common challenges in the tool manufacturing sector of labor cost and availability, as well as safety and production efficiencies. Access to skilled staff and the need for elimination of simple, repeatable tasks which could be easily automated – AIMS maximizes grinders’ productivity, and, in general, improves Overall Equipment Effectiveness. Integration with ERP systems to streamline workflows is also one of the important AIMS features.

The principles of the AIMS system are flexibility and modularity. This means each system can be tailored to an individual customer’s needs using the right building blocks – or modules. It can scale from a purely software-based monitoring solution to a fully automated manufacturing cell.

AIMS is not a single product but rather a suite or ecosystem of interconnected building blocks which can be configured to satisfy an individual customer’s requirements. Manufacturers can build their AIMS system gradually using standalone AIMS ready components, which can be easily upgraded to fully automatic when required. Customers can tackle their most pressing issues first and stagger implementation over a period of time. This staggered option makes AIMS a feasible solution for customers as they invest in this revolutionary technology and realize the potential for their business.

Jan Irzyk, AIMS Product Manager, said: “We are delighted to present a physical, working model of AIMS for customers to understand the powerful potential of truly integrated manufacturing.

“AIMS can be configured in many ways, the IMTS cell demonstrates an unattended manufacturing workflow of two varieties of endmills on one ANCA MX7 machine,” Irzyk continued. “An important part of this workflow is closed loop measurement and compensation process using ZOLLER Genius as a measurement station. Depending on an individual customer’s requirements, our system can automatically transfer a tool from the ground batch, clean it, measure required geometries and transfer the results to the respective grinder where grinding parameter compensation is taking place to achieve required dimensional tolerance of the batch.”

Visitors to ANCA’s booth can see:

- Management of data flow for the AIMS cell with the AIMS Server, which is a software suite developed by ANCA.

- How to start building AIMS capability with a simplified and ergonomic solution for pallet transfer between processes or automated laser marking with AutoMarkX.

Irzyk concluded: “In the not-too-distant future we will be able to demonstrate the AIMS capability in a production environment, which is very exciting — so watch this space, there’s much more to come.”

Booth N-237406

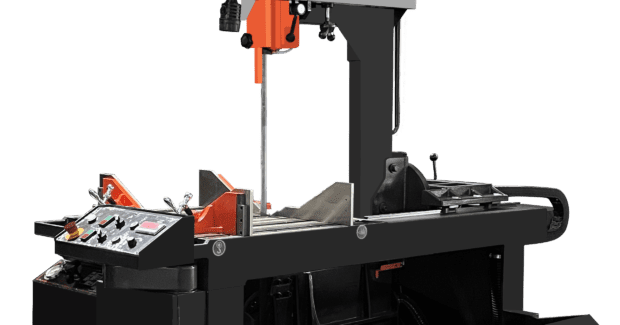

Cosen’s V-1822 is a Manual, Vertical Tilt-Frame Band Saw

Cosen Saws North America (Charlotte, NC) is proud to introduce the all-new V-1822 Vertical Tilt-Frame Band Saw to our extensive product line. In an ever changing and growing fabrication market, the need for cost effective cuttings solutions at different capacities and price points is evident. With vertical saw designs becoming more popular amongst fabricators, the V-1822 takes Cosen’s popular tilt-frame design and applies to a rigid, yet small, footprint with a 18″ x 22″ capacity. The company will be in Booth N-236931.

Developed to be a more affordable option for those in non-production settings, the saw is a manual design and allows for miter cuts ranging from 0-to-60°, both left to right. The saw comes equipped with a 1-1/4″ blade, a 5 hp blade motor, and comes standard with an adjustable 0-to-5° blade cant to help increase blade life and provide efficient cuts.

Other features include:

- Gearbox designed to accept high lateral pressure

- Adjustable flood coolant system

- Powered wire blade brush

- Carbide blade guides and guide bearings provide additional blade support

- Rigid cast-iron guide arm and bed design

- Manual blade tension device with pressure gauge

- Retractable coolant tray for easy access

- Built in table t-slots

- Wash down hose for easy cleaning

- Quick clamp and release movable and fixed vises for optimum workholding and operation efficiency

- Easy one-person blade change

Booth N-236931

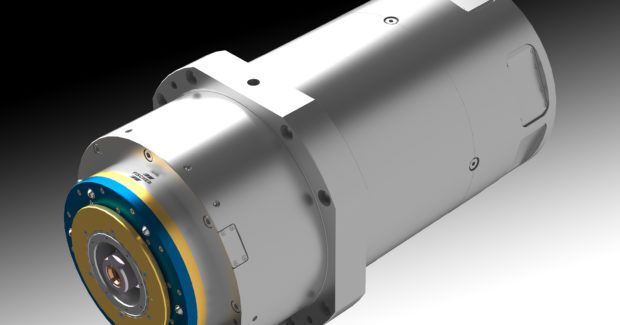

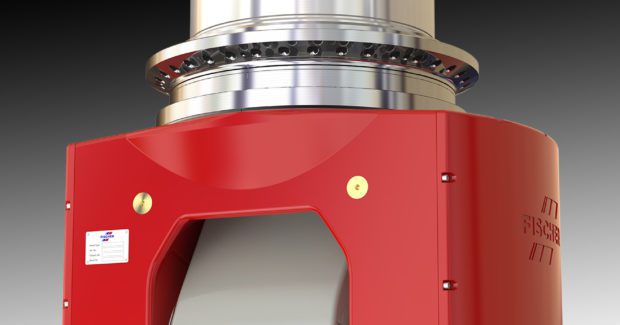

New Milling Head Spindle Combination

Under the theme of “Technology Leader with Perfect Rotation,” FISCHER USA Inc. (Racine, WI) will showcase its D27 milling head paired with its newest technology for high-volume material removal in its MFW-2714/20 HSK-100. With 80 years of experience in high-performance machine tool spindle design, in-house manufacturing and best-in-class repair services, the company will present this new design, a combination milling head-milling spindle that provides maximum stability and precision for aerospace and other 5-axis machining operations. FISCHER USA will be in Booth N-237470.

Features on this advanced milling head and spindle combination include:

Perfect Rotation – Powerful, heavy milling while maintaining accuracy and repeatability requires perfect rotation in not only the spindle but also the milling head. This is achieved by precisely calculated mono-block structures made of high-grade cast iron paired with two cross-roller bearings for A-axis and YRT for C-axis provide the highest load capacity to handle the cutting forces in all directions during power milling.

Technology Leader – Always developing and implementing industry leading technology with customer focus is a FISCHER operating principle. Highest power, highest speed, highest precision to provide customers with the leading edge.

New Milling Head – The FISCHER D27 milling head is specifically designed for the most powerful, as well as long-tooled, milling applications. With the high power and torque output, the D27 milling head still maintains its sleek symmetric outline while being dynamic and robust. To ensure accuracy and repeatability, the unit incorporates direct optical encoders, dual motors and dual clamps on the A-axis. The D27 milling head is intentionally designed to utilize the maximum power and torque capacity of the FISCHER 275 mm spindles for the highest chip removal rate.

New Spindle Design – Paired with the D27 is the spindle type MFW-2714/20 HSK-100. FISCHER is raising the bar for highest volume chip removal. The unit offers machine builders and end users a robust HSK-100 interface, max speed of 20,000 rpm and an S1 continuous power rating of 200kW.

Booth N-237470

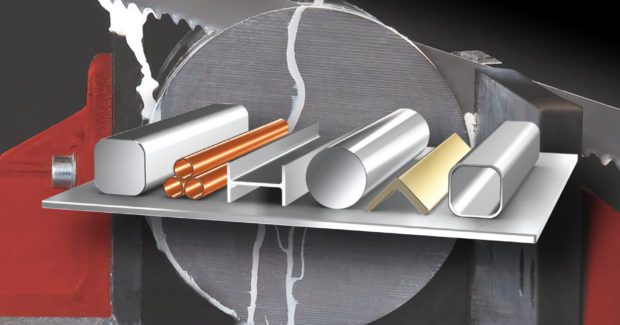

Newly Positioned IntenssTM Multi-purpose Band Saw Blades Will be Showcased

L.S. Starrett Co. (Athol, MA) a global manufacturer of precision hand tools and gages, power tool accessories, saw blades and more, will showcase its newly positioned Intenss Bi-Metal Band Saw Blades for general purpose metal sawing of a wide range of materials and shapes at Booth E-135044.

Featuring a patented process developed by Starrett called bi-metal unique® technology, which provides 170% more weld contact with the teeth, Intenss blades exhibit superior resistance to tooth strippage, significantly reducing fracture and breakage, which enables exceptionally long blade life. Performance is further enhanced by M-42 teeth with a multi-edge tooth design that produces split chips for faster cutting.

Starrett Intenss is an ideal affordable workhorse blade for general sawing in tool rooms, maintenance shops and fabricating or machine shop applications where one blade cutting a wide range of common materials with different shapes is a good sawing solution. In addition, bi-metal unique promotes long blade life so fewer blade changes are required.

Starrett Intenss Bi-Metal Blades are available in 1/2″, 3/4″ and 1″ widths and .025″ and .035″ thicknesses, featuring bi-metal unique. Blades in 1-1/4″ or 1-1/2″ widths and .035″ and .042″ thicknesses are also available, without the bi-metal unique feature. Intenss blades are offered in pitches of 10, 14 or 18, and 2-3, 3-4, 4-6 and 5-8 variable pitches. Coil lengths are available in 100′ (30 m), 150′ (45 m) or 250′ (75 m), depending on blade widths. Starrett Intenss blades are available in stock at Starrett industrial distributors or can be ordered online.

Booth E-135044

New Abrasives Process Solutions Program Solves Wide Range of Challenges

Saint-Gobain Abrasives (Worcester, MA), one of the world’s largest abrasives manufacturers, has introduced its new Norton Abrasive Process Solutions (APS) Program. The program was established to help customers determine the optimal grinding or finishing solution for the application at hand, ranging from simple to complex, off-hand or automated, and for metal fabrication, production grinding and virtually any abrasives operation. IMTS attendees can discuss the new program with Norton in Booth N-237042.

The APS Program draws upon the vast knowledge of the Norton team along with access to 30 different machines, and a new state-of-the-art APS Robotic Automation Cell, which is at the core of the APS Program located at the Higgins Grinding Technology Center in Northborough, Mass. The APS team provides abrasive process development, optimization, automation and in-house testing. Services encompass the testing and optimization of new abrasives, improving quality and/or throughput, and trying entirely new and customized processes.

The APS Program is positioned to be an extension of the customer, where tests can be conducted so that customers do not have to re-assign limited in-house resources and pause their own production. “At a time when North American manufacturers need to deliver high-quality products faster, while stressed with labor shortages, we are thrilled to announce the new APS Program which can relieve some of their burden,” said Tony Landes, APS lead for Norton | Saint-Gobain Abrasives. “The APS Program is uniquely setup to deliver a comprehensive array of services, including a quick response and short turnaround. The APS team can provide the broadest array of grinding and finishing process development solutions for any type of abrasive.”

The APS Automation Cell can deliver abrasive-to-part and part-to-abrasive applications, wet/dry processing and uses a full range of abrasives such as coated, non-woven, thin wheel, bonded and super abrasives. Equipped with a verified turnkey solution, manufacturers can then contact an automation system integrator to implement the solution. This avoids costly trial and error at the integrator level.

Regarding the robotic technology, the automation cell features an industrial robot with a 210-kg load capacity that allows the APS team to perform processes using nearly any size part or tool. The force sensor-capable robot performs in a multi-capacity role, meaning it is fitted with an end-of-arm gripper to allow for part-to-media processing, as well as tool changers that use traditional hand tools to perform abrasive-to-part processing.

An integrated robotic-centered process development system includes a programmable pivot table, 6-inch-deep coolant pans, abrasive tools, toolholders and radial compliant devices. Spindle motors and compliance slides as well as two heavy-duty grinding heads which have a 15 hp and 40 hp motor, respectively, are also in the mix. A programmable pivot head with dual belt and wheel is also offered. Belts, cut-off wheels, and grinding wheels for example, can all be accommodated on the stacked head for part-to-media applications that require heavy pressure such as casting cut-off and gate grinding. A side-by-side spindle head can use two belts and up to four radial wheels, which can produce high surface finishes by buffing or using filament brushes.

Booth N-237042

Versatile 5-axis Tool Grinder Features a Small Footprint, Large Grind Zone

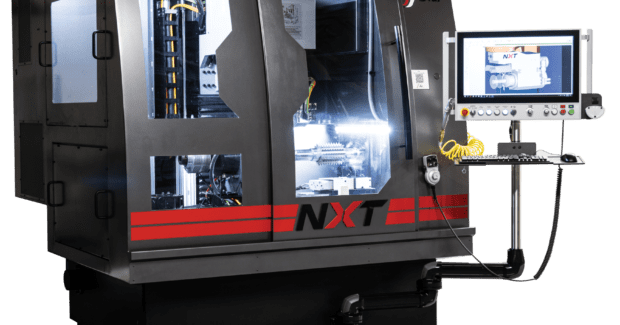

Star Cutter Co. (Farmington Hills, MI) will be displaying its newest generation automated NXT 5-axis tool grinder in Booth N-237013 featuring detailed graphics that enable visitors to take a self-guided tour of the machine, which will be shadow grinding during the show. The display system will feature the 28kW spindle option and four-station wheel change capability. It will be equipped with a robot loader and flat blade/insert clamping fixture for live demonstration of automated production. Videos to showcase tooling for form cutters, boring bars and medical hip rasps will also be on display.

The NXT is a versatile tool grinder that offers a small footprint with a large grind zone, providing the ability to run both small and large diameter wheels. Featuring a modular design, it can be easily configured to meet specific customer grinding and resharpening applications while maintaining a competitive price point.

The NXT wheel pack and coolant manifold is configurable per application with up to five stations, offering the flexibility to handle everything from high mix/low volume production through low mix/high volume applications. It also has two spindle options — a 28kW, 20,000 rpm Auto HSK for general manufacturing or a 15kW, 24,000 rpm Auto HSK for manufacturing, regrinding and high rpm applications. In addition to the automation solution, other options for process enhancement include a clearance-optimized flip-up, air-actuated tailstock and other various workholding solutions.

With the NXT, preventative maintenance is improved through real-time tracking of temperatures, spindle hours and bearing travel distances. Key to the system’s functionality is the control software, featuring the latest Flexium Tools with NUMROTO 4.3.0, as well as an ESPRIT CAD/CAM for freeform grinding with 3D simulation and special capability for medical components.

The NXT 5-axis tool grinder has a 6.5’ W by 7.5’ L footprint with a 30.2” x 19.9” x 25.6” (LWH) grinding zone and ability to run tools up to 10” (250 mm) in diameter. It has FANUC robotics automation with 0.196”-to-1.250” (5-to-32 mm) gripper assembly.

www.starcutter.com/tool-grinders/

Booth N-237013

Subscribe to learn the latest in manufacturing.