4D_Additive Software with New Nesting Functions is Faster and More Precise

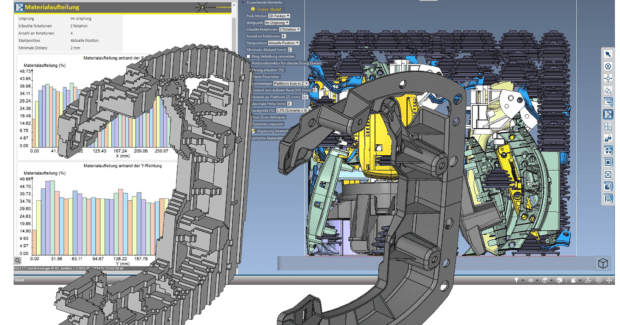

The highlight of the CoreTechnologie software’s new and optimized functions are the revised nesting functions. The current version 1.4 SP0 is equipped with many new and optimized functions.

Posted: July 8, 2022

The German-French software manufacturer CoreTechnologie has updated the renowned 4D_Additive manufacturing software. The current version 1.4 SP0 is equipped with many new and optimized functions. The highlight of the software are the revised nesting functions. Compared to the previous version, the software now has higher speed, accuracy and packing density as well as optimized packing distribution. In addition, the software has a new nesting strategy. The new powercopy nesting function allows for an extremely fast packing of identical parts with a maximum packing density.

Integration of FDM Technology

In the new 4D_Additive software version, the entire FDM process can now be mapped and enables the creation of FDM specific supports as well as the hollowing of models and special FDM hatching and slicing strategies. In addition, the realistic display of the individual layers and the resulting model is possible with a high-resolution 3D player. In addition to the STL format, the slicing data is exported in a special G-code file for Volumic and Ultimaker printers for output to the machine.

Data Optimisation and Process Management for Eos Machines

By integrating the Eosprint 2.0 interface, print data from 4D_Additive can be sent directly to Eos machines without detours via other software tools. The 3D printing software thus makes it possible to read native CAD data, prepare it for common 3D printing processes, control and optimize process parameters and send the data to Eos systems with a single tool. The Eosprint API integrated in 4D_Additive calculates the exact path of the laser during the production process and optimises factors such as build speed and surface quality. The new version 4D_Additive 1.4 supports popular Eos machines such as the M 290, M 400, M 400-4, M 300-4, P 500, M 100 and, from November 2022, the Formiga P 110 Velocis.

Automatic Scan Data Repair and STL Reduction

The highly effective “Marching Cube” function enables the repair of low-quality scan data and STL models with numerous holes, knife edges and misaligned triangles and automatically creates closed solids. In addition, the new mesh reduction function helps to reduce elements or triangles on STL models, effectively reducing the amount of data at the touch of a button. The user can set the percentage reduction, the maximum number of triangles or the permitted chord deviation

Further information is available at https://www.coretechnologie.com/products/4d-additive.html.

Subscribe to learn the latest in manufacturing.