Workholding Innovations Boost Productivity and Save Money

Take your production to the next level with products that are easy to use, adjust and change.

Posted: June 17, 2022

New and updated versions of clamping and workholding products and shrink-fit technology provide flexibility in processes and speed up changeovers. Minimal changeover results in less downtime, increases in safety and the manufacture of quality and high-precision workpieces.

Achieve Maximum Machining Stability with a Modular Stabilizer System

Part stability across the metalworking industry impacts everything from profitability to employee safety. BIG DAISHOWA Inc.’s (Hoffman Estates, IL) modular UNILOCK Stabilizer System provides lateral support for tall parts during machining, welding or assembly processes and allows for the transfer of loads down to the table or base.

In place of modifying parts by moving them from machine to machine — introducing the chance for error — this stabilizer system can easily adjust to each new part. The system attaches to the worktable and the side of the workpiece to provide lateral support. This is important because as the workpiece gets taller and further away from the table, there are cutting forces pushing against it and the stabilizer helps to offset them.

The UNILOCK Stabilizer System also can be used for mobile parts of odd shapes and sizes. No matter the part, they are easy to adjust within one job, or in the case that jobs are changing in and out rapidly. What’s more, integrating it into existing setups is quick. The system stacks easily and uses a wide variety of gripping forms.

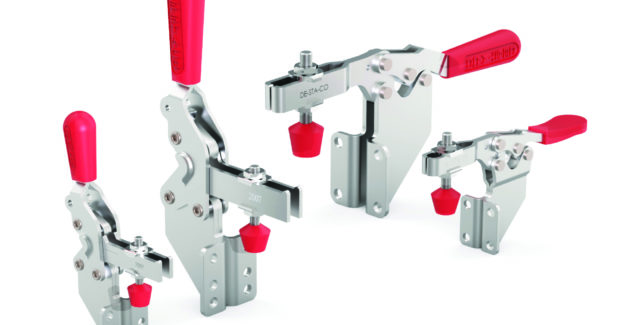

Front-Mount-Base Manual Clamps

DESTACO (Auburn Hills, MI) has expanded the range of its horizontal and vertical toggle-lock manual clamp product line with the introduction of a front-mount-base model. The compact, space-saving front-mount-base is designed to offer users additional flexibility in their workholding applications.

The front-mount option is available for inclusion on a total of four manual clamps that can be used with both vertical and horizontal handle action. The two vertical operating models — 2002-UF and 2007-UF — provide enlarged space for manual operations and increased safety. The horizontal versions – models 225-UF and 235-UF — have a flat design that creates space for larger hand clearance, which improves operational safety. The new models use the same connection-hole pattern as existing models, along with the same spindles, pin holders and bolt retainers. All models have hardened bushings at key pivot points and the design does not interfere with the mounting connections.

HAIMER Shrink Fit Power Clamp Air i4.0 Technology

HAIMER USA LLC’s (Villa Park, IL) new Power Clamp Industry 4.0 Series is setting new digital communication standards between tools and machines. The Comfort Power Clamp Air i4.0 and Economic Power Clamp Air i4.0 are integrated with a new intuitive software, a workshop 7″ touch display, and a pneumatic brake for the Air Cooling System — easily activated with release-by-touch. Keep your workplace clean and reduce the shrinking and cooling cycle to a minimum with the optional length presetting and hand scanner for scanning the shrinking parameters. Get a smooth and uncomplicated cooling of all kinds of shrink fit chucks and shrink fit collets, and for all cutting tools (solid carbide and HSS) by air — without dirt and water residue. Regardless of the outside contour, adjustable to all types of tool holders, manually turn around the coil to select the required size of the chuck with HAIMER’s Intelligent New Generation coil. No disks are necessary. HAIMER’s special procedure for temperature control assures that the frequency and the current are exactly coordinated with one another to supply electric power to the coil within seconds, without overheating the chuck, independent of the main voltage.

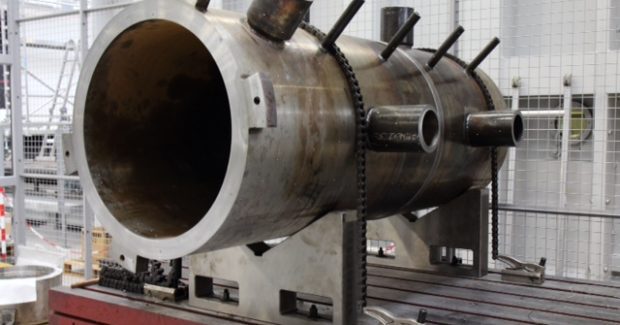

Tools for Quick Setups Save You Time and Money

Lenzkes Clamping Tools (Christiansburg, VA) is known for its high-quality workholding solutions for all types of machines. Products are applicable for machine tables/platen with t-slot and/or tapped holes and feature high clamping forces ensuring quicker and safer changes. Lenzkes’ chain clamps provide the fastest and safest way to hold round and bulky workpieces securely in place by low torque settings. The chain clamp product is very easy to adjust, which increases productivity by reducing setup time. The MQ150 and MQ160 quick release tools offer exceptional stepless, vertical and horizontal adjustment. The unique arch shaped clamping arm provides multiple options regarding clamping position. The MQ 160 provides a greater stepless horizontal adjustment due to an elongated slot in the clamping rail.

A Complete and Powerful Clamping Performance

With the WILA (Hanover, MD) AirPower Series you can boost your press brake productivity, while using a full pneumatic clamping system. Through a patented Self-Locking® mechanism, the WILA AirPower Series ensures superior clamping performance. Tools are clamped and unclamped extremely fast and tight, using only regular workshop air pressure of 6-8 bar — without the need for expensive pressure boosters.

Tools are clamped using a pneumatically controlled pair of self-adjusting wedges. When the wedges are engaged (clamped), they become an integral part of the tool. The Self-Locking principle is suitable for clamping WILA’s New Standard top and bottom tools (BIU and OZU). The Premium clamping is also released pneumatically.

The series features the V-Lock® groove at the back of the tool tang, which is used to automatically align bottom tools along the X axis and Y axis, and to firmly clamp them in place. What’s more, easier to maintain, oil-free machines are cleaner and more sustainable, using less energy as they are only running when operating. The unique innovation of the series means setup is faster, easier and more efficient.

Subscribe to learn the latest in manufacturing.