Using Modern Technology to Drive Efficiency in Job Shop Manufacturing

The necessity of adopting software bridges the office and shop floor into a single digital thread your buyers can see.

Posted: June 15, 2022

American manufacturing is becoming increasingly more digital as new technologies surface and buyers become younger and more tech-savvy. Many manufacturers are starting to think about how they can leverage modern software to digitize, automate, and streamline their processes that are currently managed by brute force. Not only is software important to increase efficiencies in the shop, but it is becoming increasingly more pertinent to stay competitive against enterprising manufacturing-as-a-service companies in the industry like Xometry, ProtoLabs, and Fictiv, which utilize more than a billion dollars in software combined to automate the manufacturing process.

Paperless Parts did a survey in 2020, and 93 percent of part buyers have sent, requested, and received quotes from one of these three companies. These companies offer quotes in hours, parts in days, and 24/7 live customer support to their buyers. This is changing buyer expectations in the industry, as part buyers are trained to expect a fast digital quoting and buying experience. Now the expectations have shifted, and the questions become: “Why does my local job shop take a week to turn around a quote? Why can’t they quickly communicate the status of a job exactly where it is in the shop? Why don’t they have that level of visibility?”

Sixty-seven percent of buyers expect a quote in less than 24 hours. This poses the question: If you are quoting something and it has been three days, is there even a job to win?

And what’s more, when the buyer places that order, they want to be able to know the status of the job instantly when they call. Anyone in the shop should know the status of where the quote is. People need access to the information that is pertinent to them. This is where software plays a critical role.

Software becomes a tool to help job shops sell their capabilities to the industry. Adopting software shows that the shop is investing in the areas of its business that make it more efficient.

How to choose where to invest?

There has been this great divide between the office and the shop in the past which needs to be broken down. Many manufacturers have sophisticated and modern CNC machines, but they are still pushing paper around the office. This is not an aligned approach, and it is important to invest in software across your entire organization. Steve Jobs used to say that the computer is the bicycle of the mind. Well, software is the key to this castle. To take advantage of all the automation and power of computing, you need to be able to access this through software.

Changing buyer expectations can only be filled by investments in digitizing the front office and the shop floor and bridging these technologies into a single digital thread.

The digital thread is a common communication framework, a connected data flow that can only be enabled with modern software, because modern software can talk to other modern software. Let’s define modern software. The key benefits of modern software are that it is cloud-based, secure, and flexible. Modern software has application programming interfaces (APIs) that allow it to integrate with other modern software to create one central place of truth for all your data.

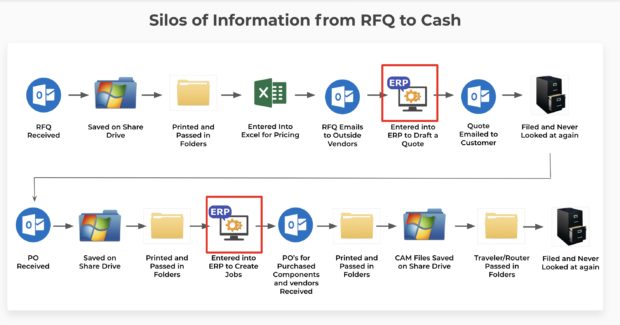

Most traditional manufacturing enterprise resource planning (ERP) systems are not genuinely designed for the machine shop industry, and they cannot be effectively used to manage tribal knowledge, or to manage things like cutting tools and inspection processes. All these things are managed outside of the ERP on spreadsheets, on paper and in other databases. Every shop has multiple silos of information, and it is all very disconnected.

Each time you break the digital thread with silos of information you are creating unnecessary risk and inefficiency in your shop. For example, losing track of an important quote because files are printed and prioritized by stacks of paper, or missing an engineering revision because it was communicated in a silo, and you lack a system that stores data in the same place. The challenge is manufacturers are losing track of important pieces of information in these silos. Double data entry into more than one system is manual and error-prone, causing huge waste.

The goal is to break down these silos of information, so manufacturers are not jumping from their email to share drive, to printed papers, to going into an excel spreadsheet, to then going to outside vendors for request for quotes (RFQs), to then entering all the data again into the ERP system, and then sending the quote out via email to customers.

This is why technology integrations between modern estimating and quoting software such as Paperless Parts, and modern ERP software such as ProShop, offer significant advantages to manufacturers.

Paperless Parts is a company that focuses on automating the estimating, quoting, sales, customer communication processes that are all managed in the front office. ProShop is a shop management ERP that focuses on execution of jobs, order management and inventory, everything that happens after the estimating and quoting process. This partnership of modern software systems provides a seamless end-to-end process that integrates quoting, design and manufacturing, and distribution data into a single digital thread for all manufacturing data within a shop.

The Challenge

The manufacturing industry is a product of legacy ERP systems that never had modern APIs to allow for software to communicate effectively. This meant these ERP systems had to be all things to everyone, which is unrealistic, and in turn, makes the systems very rigid and inflexible. Look for an ERP software that sets itself apart because it easily and intuitively helps manufacturers manage their business processes and is designed for the needs of each unique manufacturer.

For example, the seamless integration with Paperless Parts improves ProShop’s valuable underlying components, making the system even more robust and user-friendly for manufacturing sales teams. This integration offers users the automation they need to drive efficiency and speed in their quote-to-cash process, reduce mistakes by eliminating manual double-data entry, and securely collaborate and share files with customers and vendors.

Modern software that can connect to other software enables manufacturers to use the right tools for the right jobs. Adopting leading technologies with these capabilities provides manufacturers with the benefits of automation and digitization while managing risk and ensuring that their data remains secure.

The ROI

There is often a fear that software is not approachable or that the software will be too expensive. It is actually the opposite. With software enabling people to be more proactive and connected into the office and the shop, they are saving more money. For instance, our customers are quoting six times faster with software than without it, allowing them to win more business and increase their revenue. ProShop’s clients are, on average, pushing through 25 percent more product and more revenue with the same amount of people and machines.

The question to ask is, what is your capacity? Are you operating at your full capacity? Putting the right systems in place that allow you to truly access your efficiency and capacity can have a much bigger impact than adding a single machine.

Justin Quinn, president of Focused on Machining, a Denver-based CNC machine shop, did not feel like he could add a second shift because there was so much tribal knowledge that he didn’t think they would be successful off hours. Once he had the software in place to capture that tribal knowledge and disperse it across the team, he was comfortable adding that second shift and started running spindle hours more than he had before. This is a great example of free capacity that hadn’t been used before that can now be leveraged because of the benefits of modern software.

“ProShop and Paperless Parts are what software companies should be,” Quinn said. With this integration, gone are the days of paper travelers, long lead times for quotes, and internal tribal knowledge of how to successfully make parts.”

Subscribe to learn the latest in manufacturing.