Smart Connections = Smarter Shops

Whatever size your shop might be, the road to digitalization is a trip worth taking.

Posted: June 16, 2022

Everyone hears about digitalization today and most wonder if it has value for their factory. The simple answer is a resounding “yes” and the reasons are many. Through the available products, software, connection devices and cloud-based data management on the market today, a manufacturer of any size can experience ease of implementation and integration of a digital environment.

The best starting point is to find the people in your organization who have two essential talents, namely, a deep understanding of your operation coupled with a good grasp of the available technology on the market today. If such people can’t be found inside your operation, consult the growing ranks of integrators in your area. You’ll quickly locate a few with the right knowledge to help.

Digital Twin

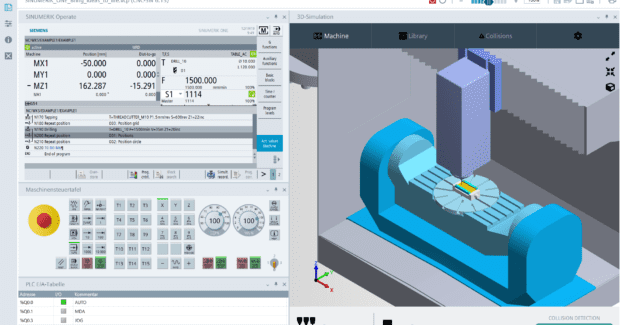

The digital twin of a machine or production process refers to the ability to accurately simulate the machine behavior in its entirety AND its kinematics under actual operating conditions. When it first arrived on the market, the achievement of a digital twin required some actual hardware such as a PLC to accomplish the goal. That is no longer the case, as the CNC can reproduce all values and movements quite accurately. Furthermore, the digital twin actually takes operating conditions into account when producing the simulation, thus the results are more accurate and representative of what real working conditions will be. Remember this is all being done before the first piece of sheetmetal is formed to make the machine.

A digital twin doesn’t act like the real machine, in fact, it IS the real machine, working under the same conditions as it will on your shop floor. Machine builders can use this technology to try out new ideas in motion, size and ancillary equipment add-ons, while the end-user community can significantly improve its operation by simulating workflow, tool changes, part handling and staging.

This notion has been in the industrial manufacturing conversation for some time. Today, it means three things. You can simulate the design of equipment in the virtual world, you can simulate the full lifecycle of a part from concept to CAD to CAM to run-time and machine kinematics in real time with in-process adjustment, plus you can now simulate the movement of people and parts through your factory to maximize production efficiencies. And, best of all, this can be done in a totally virtual environment, with no impact on your present operation. It has great benefit in the training process for current and new machine operators, programmers and maintenance personnel, too.

You can partner with your machine builder, CNC supplier or an integrator who brings the expertise and experience to guide you to the best solution for your shop. These partners will make your journey a lot easier.

A Quick Example:

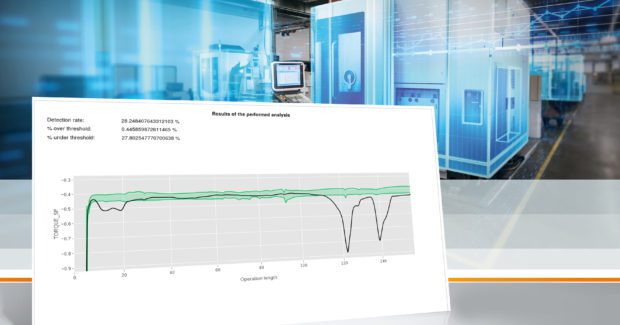

We worked with an end-user who had a known cycle time for a part. The process involved a robot and gantry movement, both of which significantly impacted the cycle time. By capturing low frequency data such as spindle and tool life, the part quality and improvement in that cycle time, running in a lights-out environment, were significantly bettered in just two months, while the overall machine condition improved over a six-month period, with the cost of the service being quickly recouped in the savings on the shop floor.

This happened as a result of a digital twin being created as a virtual representation of the CNC, HMI, total machine envelope with all the ancillary equipment simulated plus the actual part production, factoring tool wear and the full machine mechatronics. Simply put, this process is NOT an estimate of prevailing factors in the production cycle, it is the “real thing” simulated in a virtual world, with all the values being representative of the working conditions throughout a part run or workday.

Data Made Smart

There are three major processes in play, whether your operation involves chip cutting or fabrication.

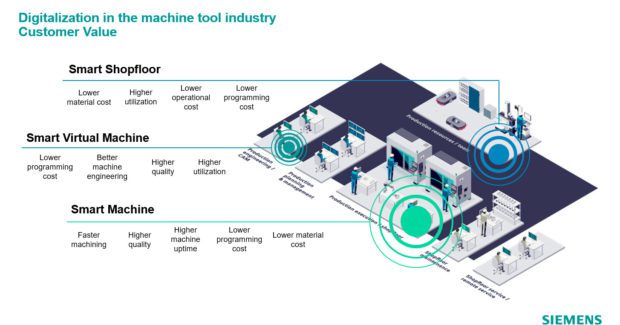

First, the smart virtual machine uses software solutions to check production in all aspects, from surface quality to machine crashes.

Next, the smart shop floor concept gathers data from your entire shop, including machine networking via control and tool monitoring to efficiently determine OEE parameters and machine uptime goals to be targeted.

Finally, the truly smart machine uses high frequency data to reduce cycle time, avoid collisions, and monitor the machining process for anomalies. This high-quality data is used in real-time at the machine and sent to upper-level systems, even the cloud, for aggregate analytics. Here’s where an additional factor becomes critical.

The controller’s ability to gather and transmit the data is NOT the same as establishing key priorities among all that data, so your machine operators and especially maintenance personnel can more quickly identify off-normal conditions, whether those be in the mechanical, electrical or electronic hardware on the machine or even in the controller itself. Advancements in the CNC memory, for example, are making it possible for machine builders and end-users alike to better capture, prioritize and resolve issues much faster and more effectively. The key here is determining which process data or alarms are most critical and how to establish reliable, real-time response protocols to address them.

A last bit of advice here is to get your team involved in the process of gathering the necessary data to feed the system and to keep them informed of the progress, with target dates and reports provided to them. It’s essential the team be onboard with the success of the smart factory and not simply to view it as added paperwork.

On the Horizon

The “next big thing” in smart controls will be the integration of the CAD/CAM and MES to the shop floor. Think of a two-way street, with the data flowing simultaneously between your machines and the cloud-based or networked control system. The result will be truly closed-loop manufacturing, that is, the transition to optimal conditions on the shop floor made possible through the gathering of more data from the machines. An exciting current example is the flow of information being developed by the MT Connect and OPC Unified Architecture organizations to achieve a companion set of specifications for a standardized language between all the machine tools, fabrication equipment, manufacturing technology devices and software platforms in industry.

Complementing this development will be the emergence of machine learning and true AI, where the machines will themselves, as our mothers taught us, “learn from our mistakes” and instantly correct the cutting tool position, stamping force, laser intensity or robotic articulation to keep the production on track to achieve the optimum conditions.

Subscribe to learn the latest in manufacturing.