New Weld Monitoring Software Offers More User-friendly Interface

Xiris Automation’s Xiris WeldStudio™ 3 and WeldStudio™ 3 Pro offer solutions such as permissions system and recipe management.

Posted: June 27, 2022

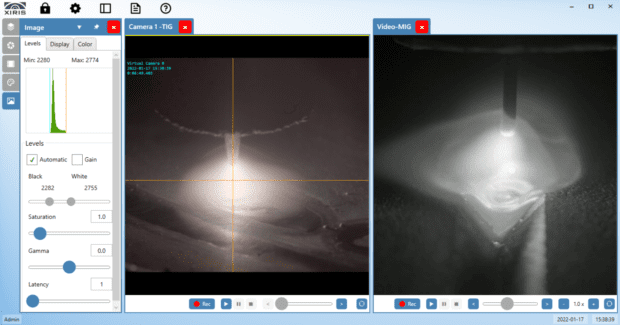

Weld monitoring of a process using a weld camera system can help verify that the best quality welds are being achieved. An important part of effective monitoring of a weld process is to use software that controls the cameras, enables recording and playback, and provides the ability to extract information about the weld image for analysis.

We are excited to announce the release of a new generation of software from Xiris Automation: Xiris WeldStudio™ 3 and WeldStudio™ 3 Pro. This software generation has several features that contribute to an even easier solution for weld monitoring such as a Permissions System, Recipe Management, and a more user-friendly interface with touchscreen controls.

Xiris Automation product manager Greg Cooke comments, “a large benefit of the recipe management and permission system is that it enables the weld camera system to start up or be put in a validated state, making it simple and easy to use, especially for industrial users and educators.” With all the same features as Xiris WeldStudio™ 3, the pro version presents additional key measurement tools, machine vision tools and compatibility with several add-ons.

Xiris Automation Inc. specializes in developing weld monitoring and inspection equipment used for process and quality control across several specialty industries. With an extensive product line of welding cameras, thermal cameras, and laser inspection systems, Xiris provides some of the world’s most dynamic manufacturers with the ability to detect, recognize, and interpret quality defects in their manufactured goods.

Subscribe to learn the latest in manufacturing.