Revolutionary Machine Vision Training with Artificial Intelligence

With the Siemens Digital Industries Software’s SynthAI™ service, machine vision specialists do not need to use complex processes to generate data.

Posted: May 2, 2022

Siemens Digital Industries Software’s SynthAI™ service is delivering the power of machine learning and artificial intelligence to solve the challenge of training machine vision systems.

“We were looking for a quick and easy solution that will enable us to detect wire terminals in a robotic electric cabinet assembly station. With SynthAI our control engineers were able to achieve great results within just a few hours,” said Omer Einav, CEO, Polygon Technologies. “The tedious task of annotating a large set of training images to train the model was shortened significantly. The results show great promise for many additional use cases we plan to handle with SynthAI.”

Machine learning is used for a variety of vision-based automation use cases such as robotic bin picking, sorting, palletizing, quality inspection and more. While usage of machine learning for vision-based automation is growing, many industries face challenges and struggle to implement it within their computer vision applications. This is due to the need to collect many images of the parts in question and the challenges associated with accurately annotating the different products within those images – particularly before production or manufacturing begins.

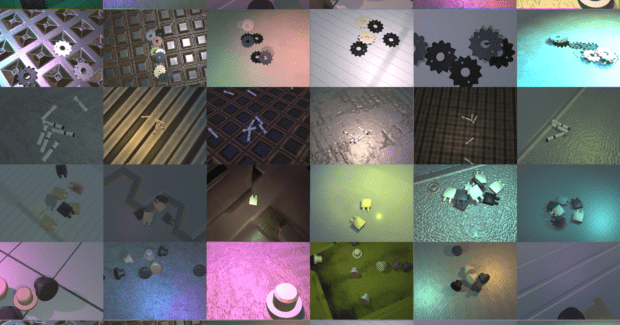

To solve this challenge, synthetic data is used to speed up the data collection and training process. However, utilizing synthetic data for vision use cases requires expertise in synthetic image generation and can be complex, time consuming, and expensive. This is where Siemens’ SynthAI changes the game.

Rather than waiting for preproduction parts to be ready or using complex processes to generate synthetic data, machine vision specialists only need to provide 3D CAD data of the parts. SynthAI will then automatically generate thousands of randomized annotated synthetic images within minutes without the specialist knowledge typically required.

SynthAI will also automatically train a machine learning model that could be used to detect your product in real life. Once the training is done, the trained model can be downloaded, tested and deployed offline – using no more than a little Python coding. If organizations prefer to handle training of their own systems, complete synthetic image datasets together with the annotations are also available.

“The market for Artificial Intelligence for Machine Vision is expected to reach $25B by 2023, but there are many challenges facing those looking to take advantage of its benefits,” said Zvi Feuer, Senior Vice President and General Manager Digital Manufacturing at Siemens Digital Industries Software. “SynthAI demonstrates how Siemens is taking its depth of knowledge in both product engineering systems as well as production preparation and planning and finding room for innovations that allow our customers to take advantage of tomorrow’s technology, today.”

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. The Xcelerator portfolio helps companies of all sizes create and leverage digital twins that provide organizations with new insights, opportunities and levels of automation to drive innovation. For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow.