Monitoring and Inspection Systems Enhance Analysis and Offer Flexibility

Inspect all of your important parameters and test parts with confidence thanks to enhanced measuring capabilities and products.

Posted: April 19, 2022

Manufacturers of tool condition monitoring and inspection, and cutting tool inspection products continue to improve processes to better to serve your needs, and your bottom line.

LaserUltra is 70% Faster Than Predecessor in Normal Tool Measurements

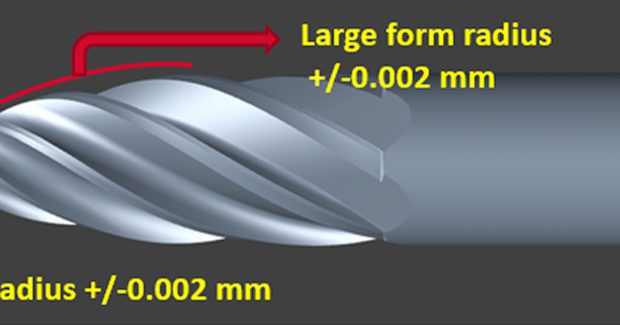

ANCA’s (Wixom, MI) LaserUltra is the next generation of the highly popular LaserPlus, an in-process measurement technology, which gave customers the power to operate unmanned overnight with the confidence to retrieve their finished tools the next day within specification.

LaserUltra allows you to achieve a 70% reduction in measurement time compared to LaserPlus through a new analog measurement. The analog measurement is a continuous edge scan instead of a number of digital points along the cutting edge. This process also eliminates variations caused by machines standing idle, errors due to manual wheel corrections and the requirement of skilled operators. LaserUltra increases accuracy, productivity, and reduction of scrap.

ANCA’s LaserUltra allows the measurement of tool geometries to tolerances of 0.002 mm without removing the tool from the grinder and ensuring maximum accuracy in measurement is maintained over large batch grinding. New tool types in the measurement cycles include barrel shape cutters and lens shapes. New operations include runout compensation and enhanced functions.

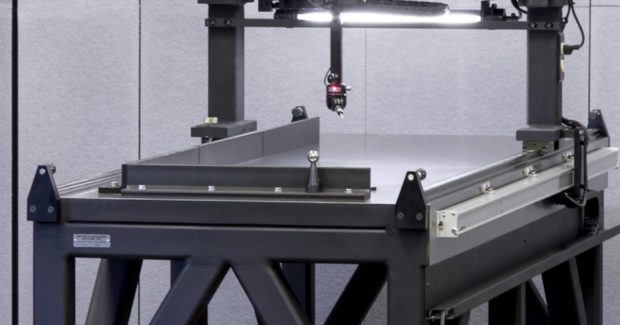

Exact Metrology Offers Raytech Measuring Tables

Exact Metrology: A Division of In-Place Machining Co. (Cincinnati, OH) is a comprehensive 3D metrology service provider and hardware sales company, and which sells Raytech Measuring Systems. These are shop-floor dimensional measuring machines such as the single-axis and the three-axis table for industrial manufacturers. The company offers machines for measuring parts for cutting, bending, punching, waterjet cutting, laser cutting, drilling and tapping. Custom machines are also available.

The single-axis table is ideal for checking flat sheets with straight edges and square corners. It features reduced setup time for production machines, reduced scrap rates and reduced backlog of parts for inspection. In addition, it integrates with SPC software for quality tracking and reporting, reduces operator-to-operator variation, offers long-term durability and simple operation. Squareness gage allows users to check sheets for perpendicularity of the edges or check edge camber, while diagonal blocks allow the user to check corner to corner squareness on sheets. All single-axis tables come standard with interchangeable probe tips.

The three-axis table is recommended for parts that are more intricate or bulkier than flat sheets. It is suitable for checking laser and waterjet cut parts, sheet metal parts with many features and parts that are bent and formed. This table includes flexible metrology software, sealed Heidenhain encoders, low-maintenance linear bearings and a versatile Renishaw indexable touch probe for flexible probing and reduced operator-to-operator inconsistency.

MiSTAR 555 CNC CMM Now with PH20 Probe

Mitutoyo America Corp. (Aurora, IL) offers the MiSTAR 555 CMM with the PH20 5-axis probe system. The best Mitutoyo shop floor CMM just got better with enhanced measuring capability, increased feature access, and a threefold improvement of throughput.

Key features include:

- Enhanced measuring capability with probe head touches

- 5-axis provides increased feature access with infinite probe angles

- Dramatic reduction in calibration time

- Compatible with the existing range of TP20 modules