Follow an Effective Roadmap to Mobile Automation

Determine the major ways an automated guided vehicle platform can be used in your shop to maximize the benefits.

Posted: April 18, 2022

Today’s flexible automated guided vehicle (AGV) platforms, including those with an added robot arm, easily automate much of the work performed by the manually driven carts commonly used in manufacturing plants and warehouses. Besides flexibility and process optimization, AGVs and the AGV platform/robot combination help protect workers from injuries and fatigue at the same time they enable superior process consistency. Like other forms of automation, these solutions enable manufacturers to leverage human intelligence for more critical operations than simply driving carts around all day.

To achieve the numerous benefits of mobile automation, manufacturers must take some key implementation considerations into account and follow essential guidelines. Doing so ensures that they apply the right mobile automation solution — whether they need to load 2 kg parts into machine tools or move 100-ton airplane wings across an assembly floor.

The Task at Hand

Most processes earmarked for automation are manual tasks performed by humans. The key question to ask is how to transfer what these employees do into an automation solution. To determine the answer, facilities must identify all the manual step-by-step actions/decisions performed to accomplish a task, then determine how automation will accomplish each of them. To illustrate, humans easily identify an item that needs to be moved, but a robot must be taught to do so, perhaps with barcodes affixed onto materials or parts.

When preparing the list of actions that make up a task, the key is to not overlook the obvious. Such a list will also help establish how much intelligence the automation requires, and which safety factors enter the picture, along with how to handle priorities and levels of interaction with humans, equipment and software.

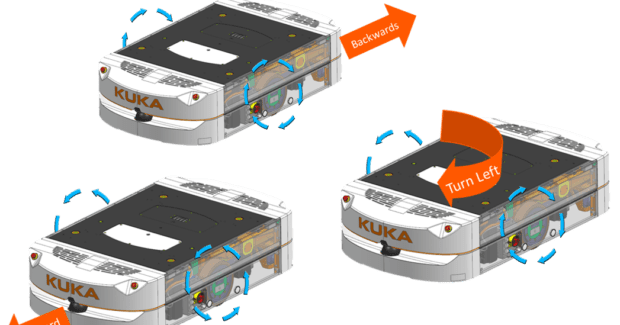

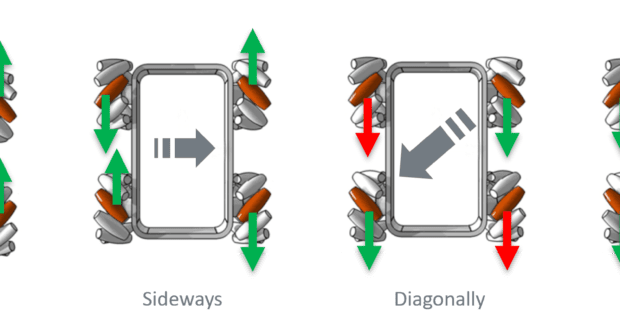

Once the tasks are determined, the next step is to decide how loads are handled and/or transported. Do they need to be carried, carted, conveyed or racked? Will they be towed, pushed or forklifted? With the answers to these questions, robot OEMs and their integrators can suggest the best way to accomplish load handling and moving, whether that’s with an AGV platform only, a platform with a collaborative robot or with a standard industrial robot or with a combination of an AGV platform and stationary robot(s). This input also helps determine if a differential drive-type platform that moves forward and back would be sufficient or if the application requires an omnidirectional one with freedom of movement in any direction.

With the type of robot selected, a facility decides on a navigation system. Typically, manual operation/guidance is recommended for extremely heavy, cumbersome loads, whereas a laser-based Light Detection and Ranging (LIDAR) system provides the most autonomous form of navigation. Although other navigation options are available, such as magnetic grids embedded in a facility’s floor, the trend has been more toward flexible laser-based systems.

Part Handling

Obviously, the sizes, shapes and weights of parts and materials will factor into the integration of mobile automation, as will the loads’ centers of gravity. With that said, parts and materials must be safely fixtured on the robot for equally safe transport to and from pickup/drop-off points.

If other equipment is also involved in the process, the automation plan must establish how the system orients and presents parts/loads properly for transitions. The plan also must determine how the platform will maneuver for those transitions with other equipment such as machine tools, while not interfering with other operations close by.

Robot Working Conditions

When integrating mobile automation, a facility’s environment, its floor conditions and foot/other vehicle traffic are all paramount considerations. For example, some robots must travel both indoors and outdoors and endure extreme temperatures, along with high humidity and other environmental challenges. In these cases, it’s essential to determine if and how the automation can handle those conditions, and whether that automation can navigate smoothly over gaps, slopes, bumps or unevenness in a facility’s floor.

In addition to floor conditions, traffic — either on foot or from other vehicles — can hinder a robot as it navigates around a facility. Likewise, the width of aisles and intersections, separation of different paths, stability and availability of physical environment features will also factor into the navigation equation.

Based on the outcomes of an evaluation of driving conditions, does the mobile robot need a separate path? Are physical facility features in place that the robot’s navigation system will reference to guide it? For instance, in a long, wide empty hall, a laser scanning navigation system would need some added relays/physical features, such as posts.

Better Safe Than Sorry

Mobile automation safety requires consideration of several application risk factors. These will influence the level and type of safety procedures and systems needed.

It goes without saying that any robot interaction with humans makes safety the highest of priorities. Facilities also need to determine the frequency of those interactions. Is human/robot interaction necessary, will it occur occasionally or never at all? These key questions must have answers to decide whether an application requires additional safety besides the inherent safety of the AGV, such as complete safety fencing or other protective system.

Like interactions with humans, robot interactions with other equipment will also raise safety concerns, especially when robots dock or load/unload. Facilities must take measures to ensure robots don’t crash into machines, other equipment or humans. Imagine the consequences of a human reaching between a moving conveyor and a stationary one during a part transfer. Robots must be able to navigate safely around unexpected conditions, such as objects left in their paths or overhanging wires.

Software

Mobile automation applications require several software systems. At the plant or warehouse level, robots will interact with master software and ERP, MES and WMS systems, as well as other plant or warehouse software systems. Some instances will call for fleet management software that connects the facility (orders) to the mobile robots to coordinate their movements and control external signals, such as to open gates or machine doors.

On the robot side, software is necessary for navigation and for communication with fleet management software. The robot itself will also house software for safety and basic driving control.

Software integration and all the other key considerations for implementing mobile automation may seem daunting. However, facilities can rely on their robot OEM and its integrators for help throughout the entire process, from planning to implementation and optimization. With highly effective tools such as simulation software, robot OEMs can determine virtually which solutions will deliver the best results for a particular mobile application. Once the system is implemented, robot OEMs provide support through the life of that system, and help manufacturers make the most of their automation solution.