Cosen Saws Provides Modern, Flexible Solutions to Sawing Aluminum

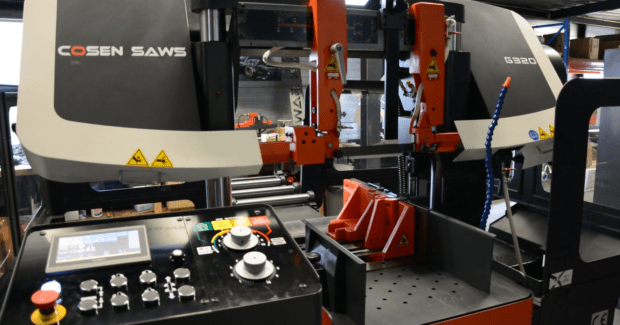

Cosen Saws’ G320 and C-Series Horizontal band saws cut different grades of aluminum; with V_Drive technology the saws cut harder denser materials.

Posted: April 6, 2022

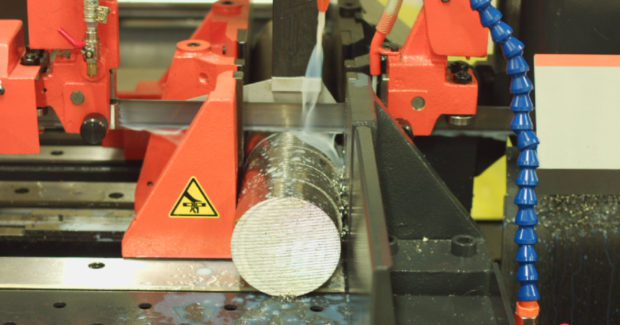

Cosen band saws with V_Drive are modern solutions for cutting aluminum efficiently. The most popular include Cosen Saws G320 and C-Series Horizontal band saws which many of our customer use to cut different grades of aluminum. With V_Drive technology, band saws are now able to cut harder denser materials like titanium, hastelloy, and other nickel-based metals at significantly increased rates. With aluminum, these machines focus on generating high blade speed with the correct combination of horsepower and torque within the gearbox and motor, so that even at high speeds the machine is not overworked and can still provide excellent cuts. Cosen’s band saws combined with big tooth blades create the right amount of clearance when cutting common types of aluminum, including 6061, 6063, 6070, and more making them the ideal solution for metal fabrication and steel service centers.

Cosen Saws G320 features a hydraulic dual column design and a capacity of 12.8″ x 15″. It is one of the smartest saws available right now and features Smart NC-100 (SNC-100) technology and V_Drive built in. SNC-100 controls are programmable up to 100 different jobs including quantity and length of cut. The controls automatically compensate for Kerf loss after data input and requires no manual calculation of number of times to index. This saw is the perfect solution for cutting a wide variety of material, including aluminum. Saws with the same technology and larger capacities are also available with Cosen’s C-Series Horizontal Band Saws.

For more traditional solutions, Cosen’s Circular Series offers specifics models designed to cut non-ferrous metals, such as aluminum and copper. The saw’s blade runs at an extremely high speed which makes it one of the fastest cutting machines on the market. Cosen’s non-ferrous machines help fulfill customer needs in a precise and efficient manner, resulting in fast cutting, tight tolerance, and a great finish. Cosen Saws Circular Series consists of the CC-100 and CC-150. These two CNC Automatic circular saws provide a round capacity of up to 6.338″ and come equipped with an automatic bar loading system. These saws are great for high volume jobs and for those cutting aluminum all day long.

When comparing different types of saws, consider that advances in band saw technology have helped expand options for cutting aluminum. Band saws provide a good solution for those looking to cut aluminum over 6″ in diameter and for those who are interested in being able to cut a wide variety of materials alongside their aluminum production. Band saws also enable a smaller capital investment in sawing aluminum and allow companies to reduce their footprint. Another benefit includes band saw blades being thinner than those of circular saw blades, this leads to less kerf loss and provides a faster return on investment.

Whether you are looking for a circular saw, band saw, or need a configurable solution to help meet your cutting needs, Cosen has you covered. Check out www.cosensaws.com to see all of our available saws and find the right one for you. Give us a call at 704-943-1030 or email [email protected] and we can assist you with any questions.