Let Hoist & Winch Lift the Burden

Hoist & Winch expertly advises customers on the most suitable equipment for their lifting requirements.

Posted: March 8, 2022

Alongside its wide portfolio of lifting and handling equipment for sale, Hoist and Winch Ltd is currently promoting its extensive know-how and experience in the hire market. The company is an expert in turnkey hire projects involving air- and electric-powered hoists, overseeing installation, commissioning, testing and certification tasks as part of a complete service package that provides genuine market differentiation.

Through its turnkey offer, Hoist & Winch expertly advises customers on the most suitable equipment for their lifting requirements, making precise arrangements to ensure safe and reliable operation. This advice is particularly important for air hoists, where the selection of a portable diesel compressor or the checking of plant air supply is necessary. Here, requirements will include specifying the optimal operating pressure, air volume, and hose length and bore size, as well as preparing and lubricating the air supply.

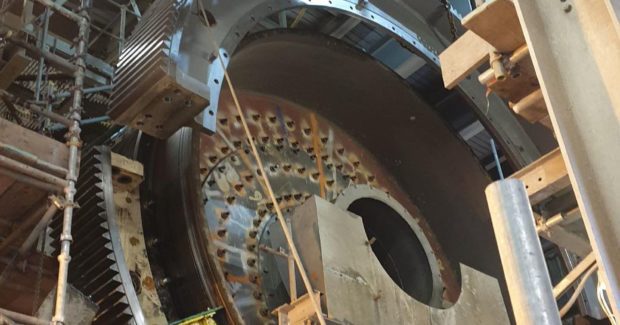

Hoist & Winch completed a notable turnkey hire project over the recent Christmas period. A customer within the building materials industry hired a special 12t swl (safe working load), twin air-powered, trolley-based air hoist for lifting and replacing a large gear weighting 9t. This type of hoist was necessary to spread the 9t load over a greater distance of the monorail beam bottom flange than a standard hoist trolley arrangement would allow.

The project was unusual in that Hoist & Winch had to first load, test and certify the monorail beam using two separate 6t swl air hoists and trolleys to support its uprating from 5t swl to the 9t load. This work was essential before the 9t gear lifts could take place for two reasons. Firstly, the special 12t swl, twin air-powered trolley hoist was not designed for negotiating the curved monorail beam section present just after the test load pick-up point. In addition, the consultant engineer’s calculations showed that the curved monorail beam section was not suitable for bearing the 11.25t proof test load. As a result, the proof test load travelled past the curved monorail beam section separately and divided equally between the two individual 6t swl air hoists/trolleys. In a further project challenge, all hoist unit side and headroom dimensional clearances were very tight and critical.

From initial consultation and equipment specification – through installation, commissioning and testing – to issuing the LOLER report, delivering handover training and providing maintenance support for the eight-week hire period, Hoist & Winch acted as the technical partner at every stage of the project. This customer, like all of the company’s customers, find that the turnkey hire service from Hoist & Winch provides assurance of a high-performance, safety-certified solution delivered on-time and on-budget.

Hoist & Winch points out that the option also exists for customers to hire stand-alone air- and electric-powered hoists for installation by their own competent personnel, if preferred.