Tube and Pipe Made Easy

New, improved and optimized machines and software boost productivity in tube and pipe projects.

Posted: February 23, 2022

Forward-looking tube and pipe manufacturers and providers of software and scanners for the inspection process ensure successful outcomes. And, when it comes to portable power tools, your operations benefit from lightweight, compact, ergonomically friendly and powerful solutions to meet your finishing goals.

Left-hand Configuration Added to ELECT Tube Bending Series

BLM GROUP USA (Novi, MI) has added left-hand configuration capability to its ELECT 102, 130 and 150 bender models, expanding this capability to the entire ELECT family, which also all include right-hand configuration. Now fabricators processing tubes or pipes with diameters of up to 6” can choose the bending direction they use most.

With multiple tool stack capability, the ELECT benders can produce fixed and variable radii in a single setup. The all-electric operation provides energy efficient production and eliminates the need for hose and piping associated with hydraulic systems. These 9-axis or 10-axis systems are well-suited for a variety of industries. The ELECT series is available with manual or automatic loading with the ability to position the automatic loader to the left or right of the machine. Additionally, they can incorporate automatic tube bundle loading and a handling robot for a complete turnkey solution that manages the entire tube loading and unloading sequence. Software for the benders eliminates trial and error programming for mistake-free production right from the start.

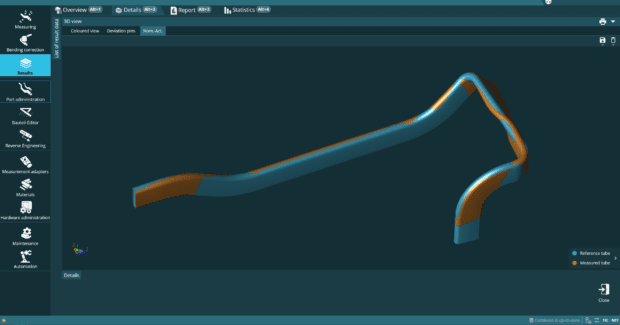

Single Software Platform for Tube Measurement

Hexagon’s Manufacturing Intelligence Division’s (North Kingstown, RI) new BendingStudio XT brings together every possibility for tube inspection, analysis and production feedback within a single software platform. It builds on the existing features of the platform to bring high-speed manual and automated camera-based measurement together with portable measuring arm functionality covering laser scanning, touch probing and infrared probing. The platform steps beyond measurement to feedback directly into the production process with connection to and control of all prominent CNC bending machine models, allowing for the simple and immediate correction of production errors. Tube measurement solutions require a high degree of flexibility, whether that’s freeform tubes, elastic wires, highly complex bends, bend-in-bend geometries, varying tube lengths, large diameters or otherwise unusual cross-sections.

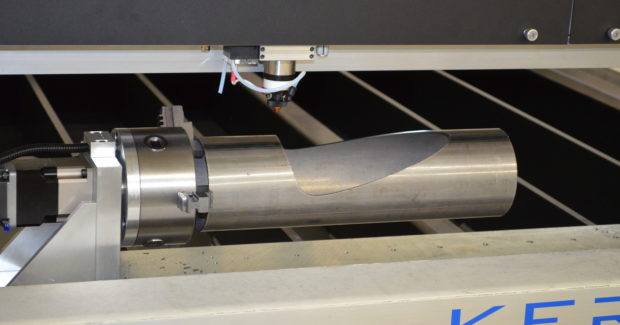

Two Rotary Setups to Process Pipes

A pipe rotary attachment can be added to any of Kern Laser Systems’ (Wadena, MN) products for the processing of pipes, rods and other cylindrical items. The rotary device is driven by a high-resolution servo motor, resulting in smooth and accurate cutting performance. Two different rotary setups are available. The chuck rotating setup implements a lathe chuck to firmly secure the pipe in place. A tailstock is pushed up against the opposite end to keep the pipe rotating on center as it cuts. The tailstock can be adjusted on a rail for different lengths of pipe. Adjustments to the rotary chuck can be made to accommodate pipes with a diameter up to 6”. The pipe cutting device is commonly used by manufacturers of exhausts, large filters and pipe joints.

An alternate rotary device uses rollers to spin a cylindrical item, allowing engravings to wrap around the entire outside surface. There is no chuck and tailstock holding the ends of the product, allowing the laser head full access to the extents of the cylindrical item. Adjustable rollers can be positioned to accommodate a variety of different sized products.

TruLaser Tube 5000 Fiber Is Even More Productive

The latest generation of TRUMPF Inc.’s (Farmington, CT) TruLaser Tube 5000 fiber machine is now 30% more productive. Packed with optimized features, the new machine gets the job done faster and tackles larger and heavier tubes than its predecessor. Users benefit from the solid-state laser technology, optimized process integration and easy machine accessibility. Tube supports keep tubes in place during machining. Step rollers automatically adapt the machine to the current tube diameter, increasing productivity and making it easier to process small batch sizes.

Thanks to its TruDisk 4001 solid-state laser the machine can handle a wide range of materials. TRUMPF has increased the maximum loading weight to 18 pounds per foot and boosted the laser power from three to four kilowatts to cut even heavier, thicker-walled tubes than before.

Users can now process square tubes with a diagonal of up to 5.12 inch and cut rectangular tubes up to an outer circle diameter of 7 inch. The RapidCut feature synchronizes the movements of the tube axis and cutting head, achieving a fourfold increase in machine dynamics when cutting small contours. The latest generation of this machine also features optimized processes and offers more powerful solid-state lasers, leading to significant gains in speed and productivity.

Progressive Portable Power Tools

Safer and Improved Magnetic Drill

Hougen Manufacturing, Inc. (Swartz Creek, MI) offers the new and improved HMD904 portable magnetic drill. With its powerful performance, lightweight size, small footprint and hole capacity, the drill is the most popular model of Hougen’s magnetic drills. A new hidden motor cord design incorporates the cord into the drill’s motor casing and housing. This major design change increases the safety of the drill and reduces maintenance to a minimum.

The overall height has been lowered by a 1-5/8”, which allows the drill to fit into tight spaces. Other features include a pilot light built into the magnet that allows the operator to more efficiently and quickly line up the pilot with the hole’s center location in low light conditions. Powering the drill is a proprietary Hougen motor with an aluminum casing to improve durability. The drill also includes a two-stage magnet, which increases magnetic holding power by 30% when the drill motor is turned on. This saves energy and increases magnet life. The arbor system utilizes a 5/8” slot drive for more rigidity, hole accuracy, positive slug ejection and quicker use of accessories such as drill chucks and tapping attachments. Made in the USA.

Compact, Powerful Mini Angle Sanders

Saint-Gobain Abrasives (Worcester, MA) offers 2″ and 3″ Norton Mini Angle Sanders. The sanders are small and compact, designed to get into hard-to-reach areas, and powerful enough to finish jobs fast and efficiently. For superb concentricity, these sanders feature a double-bearing spindle, reducing vibrations and resulting in longer use and finer finishes. A speed regulator gives users exceptional control over power and precision. An ergonomic and streamlined non-slip grip offers better tool handling as well as reduced operator fatigue. Sanding and non-woven finishing disc changes can be done quickly.

The Norton Mini Angle Sanders are well suited for deburring, sanding, blending and finishing applications in industries including metal fabrication and welding.

Quality Edges Without Post-processing

TRUMPF Inc.’s (Farmington, CT) TruTool TKA 1500 and TruTool TKA 700 edge preparation tools can produce polished metal chamfers on both straight edges and inner or outer contours, as well as radii of up to four millimeters. Designed to offer zero emissions and no flying sparks, the edge trimmer tools offer high productivity combined with simple, ergonomic operation.

Metalworkers, steelworkers and other industries use these edge preparation tools to produce clean, oxide-free edges. They are the tools of choice for chamfering metal sheets, for instance to prepare them for powder coating, painting or the application of weld seams. They are also used to round off sharp edges and remove burrs, reducing the risk of injury to workers. Angles of 30, 45 and 60 degrees can be produced in mild steel, stainless steel and aluminum depending on the requirements.

With the edge trimmer you can create custom bevel lengths of up to 15 mm with 30-, 45- and 60-degree angles. You can adjust the desired bevel length without tools. The edge preparation tool can produce chamfer lengths of up to 11 millimeters in a single pass without requiring post-processing. Setting the desired chamfer length is also a quick and painless process thanks to a 270-degree stepless dial ring for this purpose, enabling users to choose the setting they need without additional tools.