Take a Deep Dive into Measurements and Quality Control

Keep your shop running smoothly with video inspection systems that provide fast and easy visual inspections of hard-to-reach areas, and which offer your shop flexibility in the measurement process.

Posted: February 1, 2022

Video inspection systems simplify the inspection process, allowing your company to troubleshoot problems before they lead to expensive repairs. These lightweight systems not only allow you to reach difficult-to-access locations, but they also find anomalies in harsh environments, among additional advantages.

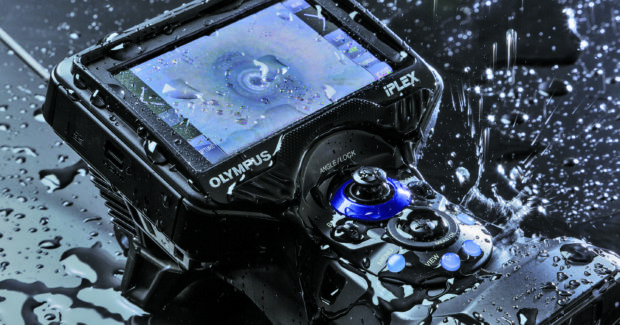

Videoscope Features the Advanced Imaging Features of Larger Videoscopes

The Olympus Corp.’s (Tokyo, Japan) IPLEX® G-Lite Videoscopes help manage quality control and visual inspection needs for the metals industry. The IPLEX G-Lite ultra-portable industrial videoscope is advantageous for fast, easy visual inspections of small or difficult-to-access locations. This videoscope incorporates the advanced imaging features of larger videoscopes, including:

- PulsarPic™ image processor constantly optimizes images by reducing halation, balancing exposure and increasing gain quality.

- An LED light source twice as bright as that of its predecessor provides improved illumination.

- A 60-frames-per-second frame rate enables users to capture smooth, clear video, even when recording a moving object. HDMI video output simplifies the data transfer process.

- Wider Dynamic Extended Range (WiDER®) technology enables inspectors to see fine details across the entire image by enhancing contrast.

To simplify the inspection process, this videoscope includes TrueFeel™ articulation and a lightweight joystick to provide precision control to help users quickly navigate to the inspection area. It automatically records the last 30 minutes of video inspections to help eliminate accidental erasure.

Small but tough, this videoscope is designed to stand up to the rigors of daily use in even the harshest conditions, including the fact they are designed to pass U.S. Department of Defense (MIL-STD-810G) four-foot drop tests.

The device is available with scopes measuring 2, 3.5, or 10 meters long in 4- or 6 mm diameters.

Thermal Camera Features the Sensitivity and Resolution to Find Hidden Deficiencies

Teledyne FLIR’s (Wilsonville, OR) E96 thermal camera is designed to help professionals identify hot spots, troubleshoot electrical and mechanical systems, and prevent problems before they cause damage that leads to expensive repairs. With a 640×480 thermal resolution and eight-times digital zoom, the E96 delivers improved measurement results over the greatest distance to target, so professionals can safely diagnose electrical faults or locate hidden anomalies at extremely high temperatures up to 1,500 degrees Celsius (2,732 degrees Fahrenheit), including in harsh industrial environments such as steel mills or other metalworking factories, to help keep the workplace running smoothly.