Methods Machine Tools Now Offers the Nakamura-Tome SC-100X2

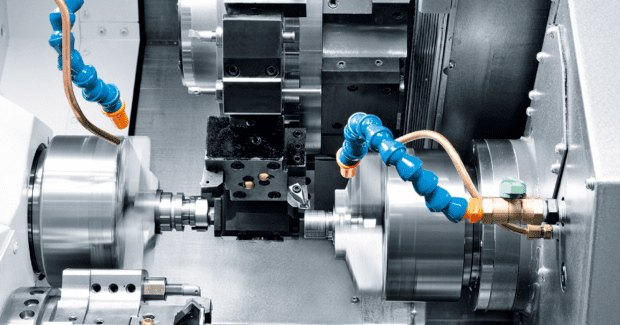

The twin-turret multitasking machine utilizes two tools on either side of the upper turret for superimposed machining, making it a logical solution for Swiss-style parts greater than 25 millimeters in diameter.

Posted: February 3, 2022

(Sudbury, MA) Reduce your cycle time and cost per piece with superimposed machining. Methods Machine Tools, Inc., the foremost supplier of high-quality machine tools in North America, recently released the NakamuraTome SC-100X2. The twin-turret multitasking machine utilizes two tools on either side of the upper turret for superimposed machining, making it a logical solution for Swiss-style parts greater than 25 millimeters in diameter.

Superimposed machining lets shops take on complex contracts and more jobs – all while completing them in a fraction of the time – compared to other machining methods. With simultaneous machining capability, machine shops can reduce their cycle times and ultimately reduce costs.

Operators can also use the upper and lower turret simultaneously, turning the SC-100X2 into a true twin spindle/twin turret machine, providing even more ways to solve complex machining problems.

“There are a ton of ways to machine complex parts on the SC-100X2, but at the end of the day the math is remarkably simple: the more tools in the cut, the less time it takes to complete a job,” said Sergio Tondato, Methods’ Sr. Director, Nakamura-Tome Product Line. “No matter what type of job you put on this machine, the results are the same; lower costs per piece.”

The unique design contributes to faster cycle times compared to other machining strategies while maintaining the same level of high precision and accuracy expected from Nakamura-Tome machines.

The SC-100X2 automatically unloads the workpiece once complete, minimizing manual intervention and downtime. When the machine completes a cycle, the parts catcher grips the part and places it on a conveyor, removing it from the machining environment. Nakamura-Tome’s user-friendly software allows you to program superimposed and multi-turret jobs as easily as single-turret operations, all accessible from a familiar FANUC 0i-TF Plus control.

The software package also includes unique features such as Nakamura’s NT-Nurse system, NTSmart Sign, NT-Navigator, oscillation turning and thermal compensation artificial intelligence for better accuracy from start to finish.

Key Specifications

Max. Turning Diameter: 7.67” Y-Axis Travel +/- 1.57”

Max. Turning Length: 15.75” Milling Turret Horsepower 9.4

Max. Bar Diameter: 2” Max. Spindle Speed (Both Spindles) 6,000 RPM