It’s All About the Connections

Improvements and advancements in chucks, collets and quick-change tooling speed up your tool changing processes.

Posted: February 1, 2022

Expanded Line of Hydraulic Chuck Offerings for Swiss lathes

BIG DAISHOWA Inc. (formerly BIG KAISER Precision Tooling Inc.) (Hoffman Estates, IL), which introduced hydraulic chucks for Swiss lathes in 2018, now includes inch-size standard type chucks, as well as new F type and R type chucks. Standard type hydraulic chucks with tool-side clamping are now available in inch sizes with the clamping range of ø1/8”, 3/16” and 1/4”.

The new F type’s single wrench enables easy cutting tool changes on the tool post. The easy-access rear clamping design is ideal for front tool post. Clamping from the opposite side of the cutting tool and optimum-length design improves overall ease of use. The F type is available in a clamping range of ø3-10 mm and coolant delivery is possible with an Rc(PT)1/8’’ screw.

The new R type eliminates interference at both the upper or lower tool post positions with a unique block design and tightening at an offset position in the tool side. The R type is available in a clamping range of ø3-10 mm and its oil hole drills can be used for coolant delivery when mounted on the upper section.

To minimize machine downtime and provide operator safety, these hydraulic chucks use a simple hex wrench that requires only two to three turns for both clamping and unclamping. Once the hydraulic chuck is centered, the runout will not vary, even if a cutting tool is changed repeatedly. Runout of fewer than three microns at four times diameter can be achieved. These chucks have a standard pipe thread for coolant-through connection and are available for most Citizen and Star machines with 3/4’’ or 22 mm straight shank.

Special Workholding Solutions Can Be Configured to Grip Any Workpiece

Dillon Manufacturing Inc.’s (Springfield, OH) special top jaws can be configured to securely grip any workpiece, including holding a components ID, OD, or a combination of both. The jaws are available in many materials with dimensions to suit the project at hand, and come as soft or hard jaws, or full grip jaws, for virtually any chuck manufacturer. Any component dimension can be altered and extra wide hard jaws provide maximum part contact and penetration. Hard jaws can be configured to accommodate different diameters; doing so without serrations eliminates marring of the workpiece surface. Extended length hard jaws can be built to grip small to medium surfaces; incorporating multiple locating diameters gives machinists flexibility and the capability for quick changeover. Tapered angle serrated surfaces that mirror the draft angle of the parts to be machined, can be designed.

Expanded Line of End Mills Ideal For High Performance Aerospace Machining

EMUGE Corp. offers an expanded line of TiNox-Cut End Mills, which are designed for high-performance machining of demanding materials such as Inconel/ nickel alloys, titanium and stainless steel found in aerospace and other challenging applications. EMUGE-FRANKEN USA is based in West Boylston, Mass. There are now four TiNox-Cut End Mill series offered, including the new 5-Flute N, NF, Base, and Trochoidal tools.

TiNox-Cut N, NF and Trochoidal End Mills are available in axial internal coolant-through capability for maximum chip evacuation and cooling ability. TiNox-Cut N and TiNox-Cut Trochoidal tools are available in both square-end and corner radius configurations. Weldon flat shank construction is available in both TiNox-Cut NF and TiNox-Cut Trochoidal tools, and is compatible with Emuge FPC Milling Chucks featuring an anti-pullout pin lock system. Overall, the expanded line includes tools that are available in inch sizes ranging from ¼ʺ to 1ʺ in diameter, and in stub, standard, long and extra-long lengths.

www.emuge.com/products/end-mills/tinox-cut

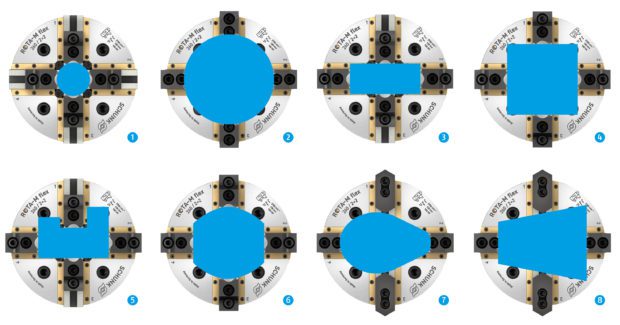

Low-maintenance 2+2 Chuck Jaw Designed to Meet Increasing Demands of the Market

The ROTA-M flex 2+2 from SCHUNK (Morrisville, NC) is a low-maintenance 2+2 chuck jaw specially designed for meeting the increasing demands of the market. The patent-pending compensating mechanism provides a longer compensation stroke than other available 4-jaw chucks on the market. Depending on the size, it amounts to 5.1 mm up to 10 mm per jaw. The result is increased flexibility for clampable workpiece geometries and a wide variety of possible applications. In many cases a single ROTA-M flex 2+2 chuck is sufficient for covering a wide range of part geometries.

The chuck’s clamping is done in a self-locking manner, and the clamping condition is signaled via indicating pins. The standard chuck sizes 260 to 1200 achieve jaw strokes from 9.5 mm to 17.8 mm and high clamping forces from 100 kN to 180 kN.

As of size 800, users benefit from the weight-reduced design. The chuck face is equipped with grooves, and fixed stops allow the chuck to also be used as a vise. Moreover, the large sizes are designed for use on vertical lathes. The chuck is equipped with a flexible serration (1.5 mm x 60° or 1/16“x 90°).