Fantastic Form

Fabricators can select from diverse and extensive lines of equipment to meet the exacting needs of their customers.

Posted: February 2, 2022

Learn the latest product news regarding ironworkers, bending, plate rolling and punching equipment from leading manufacturers of metal fabrication and forming equipment.

Diverse Lineup of Plate Rolling Equipment

KAAST Machine Tools Inc. (Aldan, PA) offers five models of plate rolling machines: the RBD-3M, the RBD-3HL, the RBD-4H, the RBD-4HD, and the RBD-4HL. Occasionally referred to as “roll bending machines” or “plate bending machines,” plate rolls are ideal for turning sheet metal into cylinders or radiused parts. The common use for plate rolls is rolling large quantities of cylinders over the course of a single day, although they can also roll conical shapes by tilting the rollers or using conical shaped rollers. The RBD-4H series rollers, pictured here, are heavy-duty plate rolls, accommodating the needs of a variety of businesses, including the shipbuilding, trucking, wind power and construction sectors. The four rolls of this hydraulic plate bending machine are equipped with high-quality, heavy-duty ball bearings, ensuring minimum friction while assuring even rotation of the rollers. The RBD-4H series accommodates 14 Ga3 /8” plate thickness and is available in lengths between 2’-to-13’.

The Compact That gets Smarter and Smarter

The P2 panel bender from Salvagnini America Inc. (Hamilton, OH) is even more flexible and productive thanks to the MAC3.0 function. The P2 features a footprint lower than 35 m2, yet with all the features of the P4. This highly successful compact panel bender reduces re-tooling times when passing from one production item to the next and minimizes — indeed eliminates — waste. A machine that the company continues to perfect, it features new hardware and software solutions to further extend its field of application. The CUT tool not only allows the machine to complete up to 17 bends per minute but also to cut profiles. This helps to make it not only an extremely high-performing and versatile bending machine but also an authentic smart work center, relieving operators of all tasks apart from simple loading and unloading, and allowing them to devote more time to other operations. The MAC3.0 is a set of integrated technologies — sensors, formulas and algorithms — to make the P2 even more intelligent. Among its many advantages, the MAC3.0 allows the P2 to adapt to the material being machined by measuring the tensile strength in real time and comparing it to the reference values of some of the most common materials on the market. The MAC3.0 comes standard on all Salvagnini panel benders.

50-Ton Ironworker with Three-Station Revolving Turret Features Quick Change Punches

Scotchman Industries Inc.’s (Philip, S.D.) 5014-ET 50-Ton Ironworker features a three-station revolving turret that accepts up to three different punch sizes, changeable in seconds, reducing setup times and increasing productivity. For additional automation, the 5014-ET Ironworker can be equipped with manual or semi-automatic feeding systems. These optional systems include a 5’ x 24” conveyor with angle iron to support higher production applications. This hydraulic ironworker is a single operator design with seven total stations. It features 50 tons of pressure and can punch a 13/16″ hole in a 3/4″ plate. Comes standard with an angle shear capable of shearing 4″ x 4″ x 3/8″ angle iron, a flat bar shear that can shear 3/4″ x 4″ to 1/4″ x 14″, and rectangle notcher for notching up to 2-1/2″ x 3″ in 5/16″ material. Standard electric stroke control makes the 5014-ET machine very accurate for bending, punching, shearing and notching operations. A remote foot pedal and punch slug receptacle are additional standard features.

With its component tool table design, the 5015-ET cab accepts optional equipment, such as the 12″ press brake, rod shear, square tube shear, picket tools and pipe notcher, greatly expanding fabricating capabilities. Custom tooling to meet unique sizes or shapes is also available. The 5014-ET is proudly made in the USA and is backed by Scotchman’s Best in the Business three-year warranty. Scotchman offers a complete line of ironworkers ranging from 45-to-150 tons of hydraulic pressure.

Sunrise Ironworkers Introduces New Autoloader for its Angle Line System

Sunrise Ironworkers has introduced an automatic autoloader for its angle line system. The new autoloader is capable of placing up to eight sticks of varying sizes onto the rack and pinion in-feed of the Sunrise Angle processing line. With capacities up to 40’ and up to 6″ angle, the fully automatic system can shear and punch automatically without slug loss, and with a 0.004″ accuracy.

Trilogy Machinery Inc. (Belcamp, Md.) is the exclusive U.S. distributor of Sunrise Ironworkers and other Sunrise equipment.

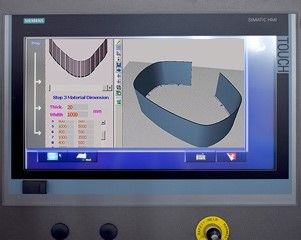

Danser of West Virginia Installs new SweBend CNC Plate Bending Roll

Danser recently installed a new, state-of-the-art CNC Plate Bending Roll by SweBend. Showcasing the latest CNC Software from SweBend, Danser can make highly precise and repeatable bends automatically on a wide variety of their products. Trilogy Machinery Inc. (Belcamp, Md.) is the exclusive North American distributor of SweBend equipment.

Committed to Success: Carell Corporation and Eagle Bending Machines, Inc.

Carell Corporation and Eagle Bending Machines, Inc. (Stapleton, AL) brings you more than 28 years of worldwide industrial fabricating and manufacturing solutions committed to the highest standards of quality and performance. Ready to help you take your efficiency to the next level.

New for 2022: 4 Roll Plate Roll. Experience the “New Era” of plate roll technology with the “Stradivari” CNC 3D-CAD Graphic control that includes diagnostic function of machine components. Any Carell VBH machine equipped with “FAST” CNC controls can now upgrade to the Stradivari with simple plug and play installation. VBH models are available with capacities from 6″ to 16 gage.

Tube and Pipe: “New” ETM-H & ACH Series CNC Mandrel Benders. ETM-H semi-automatic bending machines perform bending automatically, while feeding and rotation of the tube is performed manually. ACH Series machines are fully automatic CNC tube benders designed for linear tube bending up to 2-1/2 inches with up to 5 CNC controlled axes, servomotor-controlled bend angle, DBB, POB, two stack former head, hydraulic clamping and mandrel extraction.

“New” ETM-80HD, ETM-120HD & ETM-150HD, powerful and precise non-mandrel counter-matrix systems that allow less mechanical effort for faster cycle times than similar machines. The Digital Bend Programming 7″ Touchscreen displays 99 programs of five bends each, maximum capacity and minimum radius calculators, spring back compensation, maintenance notices, limit warnings and alarms.

Section Benders: BA40 & BA55 Section Benders incorporate “PROBENDING” Leading Edge Technology providing material feeds from left or right, three driven rolls, Servo-Valve actuated variable speed forming rolls and a 15″ LINUX-based independent console with Direct Radius Readout input option for an accurate universal machine.

The “NEW” CPS-20 H/V’s advantage of operating in both horizontal and vertical working planes now offers an optional base for dedicated use in the horizontal position. Ready for rapid delivery.

www.eaglebendingmachines.com and www.carellcorp.com