Enhance Workflow With the Latest Metrology Resources

Innovations in measurement and inspection products capture data in easy-to-understand formats.

Posted: February 22, 2022

The latest developments in 3D metrology, lasers and scanners enable shops to take a deeper look inside all sizes of castings and components to provide accurate measurements and metrology grade point cloud generation.

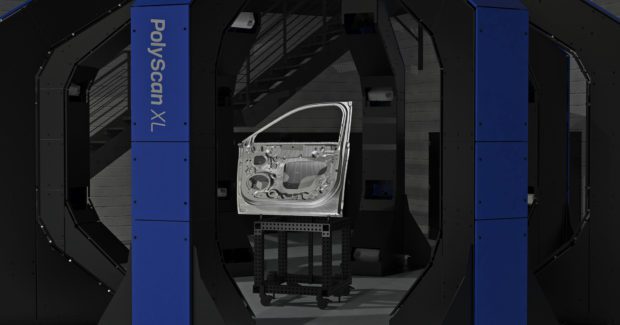

Exact Metrology Offers the PolyScan XL

Exact Metrology: A Division of In-Place Machining Co. (Brookfield, WI) proudly represents PolyScan XL. Part of the Polyrix PolyScan™ Surround 3D Scanner family, these scanners are motionless by design during the inspection. Their unique calibration avoids the need for data alignment or sticker targets, and multiple baselines increase accuracy when measuring points.

The PolyScan XL6 is designed to measure parts up to 1,600 mm, combining 12 cameras and 12 projectors to provide 210 effective scanning units. It is ideal for medium-to-large aerospace castings or automotive sheet metal components. Complete inspection of parts is achieved in just six minutes. Surround design and simplicity of automation means it can be easily integrated into a production line, while being 100% safe for operators.

PolyScan XL8 is designed to measure parts up to 2,000 mm. It combines 16 cameras and 16 projectors to provide 376 effective scanning units.

Reengineered Handheld Metrology Grade 3D Scanner

Automated Precision Inc. (Rockville, MD), the inventor of the Laser Tracker, introduces the next generation of the iScan3DTM Laser Scanner, which features improved optics and blue crossed laser lines for fast and accurate metrology grade point cloud generation. It is designed for portable shop-floor dimensional inspection and scanning markets to provide both accurate measurements and point-cloud generation from a single-handed ergonomic sensor. iScan3D, with integral process controller, connects with API’s Radian Six Degrees of Freedom (6DoF) Laser Tracker to accurately monitor scanner position and deliver high accuracy measuring and scanning. iScan3D combines tactile and scanning measurements, so users can measure wherever and whenever, regardless of part size and feature locations, in a single setup.

iScan3D features include:

- Blue crossed laser lines to allow scanning in any direction with ease and flexibility.

- Fast measurements with metrology accuracy – 200,000 points per second with 70µ point spacing and 50µ accuracy.

- Integrated tactile probing for CMM style measurement of internal and external features.

LEXT™ OLS5100 3D Laser Scanning Microscope

The Olympus Corp.’s (Tokyo, Japan) LEXT OLS5100 3D Laser Scanning Microscope is built for failure analysis and material engineering research. Combined with exceptional measurement accuracy and optical performance, the product allows you to precisely measure shape and surface roughness at the submicron level quickly to simplify your workflow, with data you can trust.

- Simplify Your Measurement Testing Workflow: The LEXT OLS5100 microscope’s Smart Experiment Manager* helps make your experiment workflow simpler by automating time-consuming tasks. Automatically create your experiment plan, auto populate data to your experiment plan matrix, and reduce the chance of input errors. Use clear data trend visualization tools to enhance workflow.

- Data You Can Trust: Objectives designed for LEXT microscopes deliver highly accurate data, enabling Olympus to guarantee the microscope’s measurement accuracy. Paired with the Smart Lens Advisor, you acquire highly accurate data with confidence. Dedicated LEXT optics optimized for the 405 nm wavelength of light reduces aberration to capture the correct shape throughout the entire field of view. The Smart Lens Advisor helps you choose the right objective lens for your roughness measurement.

- Reliable Data at the Push of a Button: Using the LEXT OLS5100 microscope is easy for novice and experienced users thanks to thoughtfully designed software. Acquire accurate data easily with the push of a button. Measurement performance is guaranteed to be tailored to your operating environment.