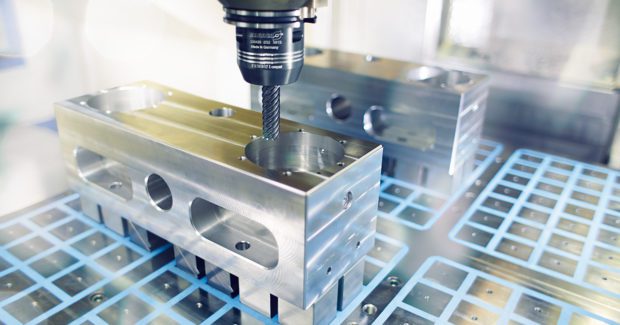

Best Practices for Reducing Consumable Costs and Extending Tool Life

Monitor and evaluate tool life to remain competitive and reduce waste.

Posted: February 2, 2022

Costs always seem to be rising, which is especially true in today’s manufacturing environment. Particularly when looking at that those fancy carbide coated cutting tools we all use on a regular basis. Searching for alternative, cheaper tools is always one option. However, before investing time and effort in finding and testing new tools, it is best to make sure the full life of the current tool is being realized. This could be as simple as checking that personnel know to use all the cutting edges on an indexable insert before discarding. Really! That little tidbit isn’t enough to justify an article on extending tool life though, so below are some process and application details that help make sure a cutting tool will meet its full potential.

- Choosing the right cutting tool for the workpiece material and operation. There are thousands upon thousands of cutting tools to choose from. All with various lengths of cut, coatings, helix angles, flute count, etc. All these specs make a difference in the performance of a cutting tool for a particular application. Taking a seven-flute end mill and trying to rough out aluminum will probably result in frustration and flutes gummed up with chips, leading to premature tool failure. The best bet here is to consult the cutting tool manufacturer’s resources. Tool manufacturers design the tools with a specific intent, using the tool for that intended process is going to result in the best performance. Cutting tool catalogs will break down cutting tools by material and cutting tool type so customers can quickly find that chamfer mill they need for 304 Stainless Steel.

- Running correct feeds, speeds and depths of cut. Now that the right tool has been selected, it must be run properly. Running too fast or too slow all present different problems regarding tool life. Whether it results in more heat being generated from rubbing or ineffective chip formation, or tool deflection from large cutting forces, it will result in suboptimal tool life. Again, just like in selecting the right cutting tool, the cutting tool manufacturer is the best resource here. They have designed the tool with a specific intent, and in that process determined how that tool should run for the best performance. The manufacturer will typically specify a cutting speed as the velocity at which the cutting edge is moving relative to the workpiece, in the United States given as Surface Feet per Minute (SFM). They will also specify a feed or the depth/thickness of cut that one cutting edge can make. For example, in end mills it is common to specify the “chip load” in a value of inch per tooth, or the bite that one flute on that end mill can take out of the workpiece. This speed and feed value are usually calculated into an RPM and feed rate at the machine, so making sure they are consistent is key.

Lastly, the manufacturer will specify depths of cut. Going back to the end mill example, it would be Axial Depth of Cut (ADOC), or the plunge of the end mill relative to the workpiece, and Radial Depth of Cut (RDOC). Too much engagement in either axial or radial will result in tool deflection and reduced life. The cutting tool manufacturers will specify different cutting parameters for roughing and finishing on a tool suitable for both operations, so it is important to consider the operation and choosing the right operating parameters for that.

- Reducing run-out and considering its sources. Once a tool is in action, the top tool life killer is run-out. The old machinist’s tale is, “every tenth of run-out reduces tool life by 10 percent.” That adds up considering all the components that affect run-out of the cutting edge. Tool changer alignment can affect how the tool and toolholder are placed in the spindle. Drawbar force and accuracy of the spindle itself influence the position of the toolholder. The pull stud to toolholder interface is another area to consider. All of that before even getting to the cutting tool. What is important here is making sure everything upstream is taken care of. Making sure the machine tool is in good operating condition. Regularly checking drawbar force and spindle run-out is always a good idea. Make sure that chips are not inadvertently being blown into the spindle during tool changes or contaminating the contact surfaces. Using quality components closer to the cutting tool, like precision toolholders, which help make sure the cutting tool stays true to the spindle. Precision toolholders, like hydraulic toolholders, will repeat over the life of the holder. Consistently placing the cutting tool on the machine spindle centerline. If tool life is lower than expected it is always worth checking how true the tool is running.

The three points mentioned above offer great starting points for squeezing a few extra minutes of cut time out of tools or troubleshooting tool life. Other factors like coolant, or programming considerations can also influence tool life. The best source of knowledge and gage for whether the cutting tools are meeting life expectations is the cutting tool manufacturer. Eventually all cutting tools wear, but to remain competitive and reduce waste, monitoring and evaluating tool life is a worthwhile venture.

For more information go to www.us.schunk.com.