THE AUTOMATING OF COST ESTIMATES: aPriori and its Software

aPriori’s cost-estimating software can benefit

1. engineers designing parts,

2. companies outsourcing the manufacture of parts, and

3. contract manufacturers bidding on jobs. For all three types of users, the software offers quick, accurate, money-saving analysis.

Posted: January 30, 2022

A design engineer sits at his desk, looking at his computer screen, at the 3D CAD model he just completed. The part is in good order—the correct material was specified; the needed features were included—but is the part in line with its cost target?

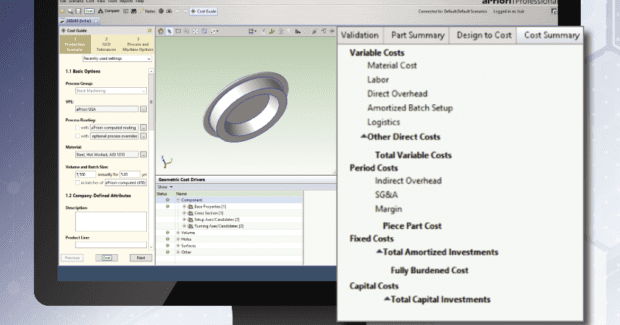

For the answer, the engineer needs a cost estimate. So, he connects to his cost-estimating software, a suite of programs from the company aPriori, and uses the software on his CAD model. A few minutes later, he looks at the computer-generated estimate.

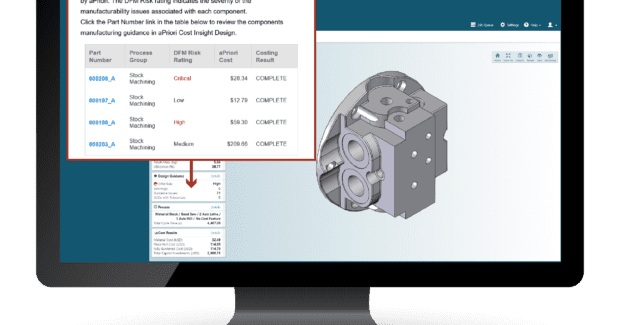

Unfortunately, he’s over his cost target. So, he looks again at his model, this time through his aPriori software. Now, the part has two features that are highlighted: one feature in yellow, the other in red.

Those are the features that are difficult to manufacture, as identified by the aPriori software. The feature highlighted in yellow is difficult to make, the feature in red is very difficult to make. Being difficult, the two features are likely driving the part above its cost target.

However, the aPriori software also identified possible alternative ways to manufacture the two features, so the engineer opens the needed window on his computer screen and continues his work on the part.

SAVE MONEY BY DESIGN

In the design phase, the money saved on a part can be dramatic. “Because 80 percent of the costs are locked in when the design is done,” said Stephanie Feraday, CEO of aPriori in Concord, Mass. (The company’s name is pronounced “ah-pre-or-e.”)

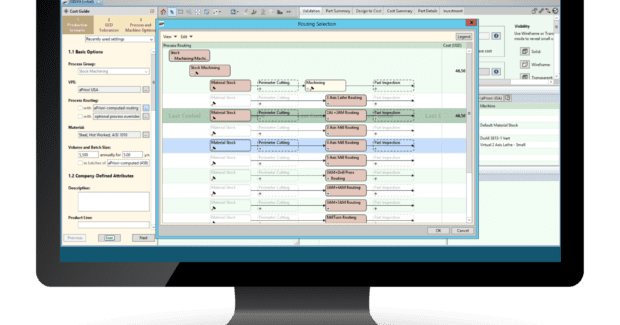

The money saved was dramatic for a defense contractor. A new aPriori customer, the contractor was bidding on a job. As it happened, the part was still in a late stage of the design phase. That was fortunate for the contractor. Although it had bid on the job, the contractor’s costs were too high. Even if the contractor won the bid, “it wouldn’t have been profitable enough for them to actually continue,” Feraday said.

So, with aPriori’s help, the contractor reviewed the cost estimate generated by aPriori’s software. The contractor looked at the different ways that the part could be manufactured and realized it had made a poor assumption about the part. “Although they had assumed it would be machined, it was actually going to be significantly less expensive if they were to cast the parts,” Feraday said.

The contractor then got in touch with the buyer about its part. The timing was vital. The buyer hadn’t yet finished the part’s design phase, so contractor and buyer discussed manufacturing the part by casting it. And the money saved from casting the part? Feraday said the contractor could save “about $100 million over the five-year project.”

With the aPriori software, the defense contractor found a way to 1) stay in the bidding process and 2) profit if it won the job.

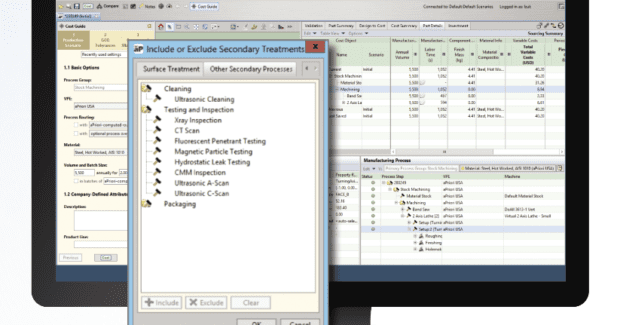

The software was able to identify casting as a less expensive process because

casting is one of more than 400 manufacturing simulations that aPriori’s software can run. “We identify all of the feasible ways that that part or assembly can be made, right down to the individual steps in the manufacturing process,” Feraday said.

EXPANDING THE SOFTWARE

aPriori the cost-estimating software has that many simulations because aPriori the company—its people—put in the time and effort to create a comprehensive program for manufacturers.

In the late 2000s, when the company was still a start-up, the software focused on the manufacture of sheet-metal parts. Its simulations consisted of the processes used to make those parts. The software also focused, to a lesser extent, on welding. (See IT ALL STARTED WITH AN INTERN on page 45.) Feraday described the simulations as “a strong set of capabilities, but very narrow.” Moreover, the simulations could be run with models from only one CAD program: PTC’s ProE.

To be useful to more manufacturers, the software needed to be broadened. aPriori started with the range of manufacturing simulations. The company also broadened the software’s ability to read CAD models from different programs.

“Now, we support over 400 different manufacturing simulations,” Feraday said. “We support all of the major CAD products on the market.” She added that: “We integrate into the PLM systems.”

aPriori also expanded its software to include databases that the company calls “regional data libraries.” The libraries provide information on many factors included in a cost estimate. For example, one library includes information on materials, such as their properties and costs. A second library includes labor rates from 80 regions around the world, and a third library has data on overhead expenses, like electricity.

The libraries were created by an aPriori sourcing team. On a continuing basis, the team members collect the data that populate the libraries. However, Feraday said each type of data doesn’t come from one source. Team members have to research a variety of sources. Feraday provided an example: material rates. One source of those rates is the London Metal Exchange. However, a company can’t assume that its supplier in Western Europe will get its material from that region. The supplier may be sourcing its material from another region.

Feraday also cited labor rates. In the U.S., the rates can be obtained from the U.S. Bureau of Labor Statistics. But, what if a possible supplier in the U.S. has factories in several other countries? “You have to go to all of their different regions,” Feraday said. “So, we use a range of sources for labor rates.”

In addition to those expansions, aPriori also developed the software so design engineers received visual feedback on their parts, on the effects of their design choices.

VISUAL FEEDBACK ON A DESIGN

The feedback indicates the manufacturability of a part based on its design, so aPriori calls the feedback its ‘design for manufacturability’ guidance.

The guidance works as described earlier. In the aPriori software, if a part has features that are difficult to manufacture, they’ll be highlighted in yellow or red. Feraday said about the highlighted features: “They’re going to drive increased cost.”

The design engineer can then click on a highlighted feature, and the software will provide information on why the feature is difficult to manufacture and will provide suggestions on how the feature could be made with less difficulty.

Feraday said that with this additional software in place, design engineers could get early, visual guidance in a digestible form that enabled them to act on the data.

VISUAL FEEDBACK: A MILESTONE

Visual feedback was an important development for the software’s users. Specifically, it changed who were the main users of the software. When it was first developed, the cost-estimating software was mainly used by a company’s cost experts.

Design engineers created CAD models of their parts, then sent the models to the cost experts for estimates. The experts then ran the models through the aPriori software. At that point in its development, the software could generate a cost estimate in a few minutes. However, the turnaround time for the estimate could be several hours, perhaps even a day.

The problem was: A company’s design engineers usually outnumbered its cost experts. The experts might have several—even many—designs that needed cost estimating. Their queues could be long, so their turnaround times could be long.

However, after aPriori implemented its visual feedback, the software started to be used more and more by design engineers. It continued to be used by cost experts, but they used it less often than they had. Feraday said the experts tended to become involved only with the more complicated cost estimates.

Today, given aPriori’s major additions, the suite of programs can estimate the cost of manufacturing parts around the world—and can do it for both large and small companies.

CUSTOMERS: BIG AND SMALL

In 2009, when she joined aPriori, Feraday said she was struck that “a very small start-up” had “some very large customers.”

Today, though, aPriori has developed its software so both large and small companies can use it. Specifically, aPriori has put its software on the cloud. For most of its history, the company installed its software on the premises of its customers, in their computer networks. That was fine when the customer was a large company.

However, the smaller the company, the fewer IT staff it has—if any. For those companies, it can be difficult to administer a suite of on-site programs that requires periodic updates, like to its regional data libraries because their data can become outdated. As examples, a region’s electricity rates can change, or another region’s labor rates can change.

Consequently, for smaller companies: “It’s much more advantageous for them to have somebody who’s hosting the software, who’s doing the upgrades,” Feraday said.

Another feature that helps smaller companies is the software’s ability to read CAD models from different programs. “We have the ability to read in many different file formats into our system,” Feraday said. She added that smaller companies: “They don’t even need a CAD system so long as they have the CAD model.”

The feature is useful to many large companies, too. A large manufacturer may have several divisions, with each one using a different CAD program. “So, it’s beneficial for us to be able to read all CAD environments,” Feraday said, “but it’s particularly beneficial for the smaller companies.”

Currently, the smallest companies served by aPriori have annual revenues of $25 million to $50 million.

ADDITIONAL USERS: SUPPLIERS

Initially, aPriori developed its software with one type of user in mind: a company that either 1) designed and manufactured its own parts or 2) designed its parts but had outside companies manufacture them.

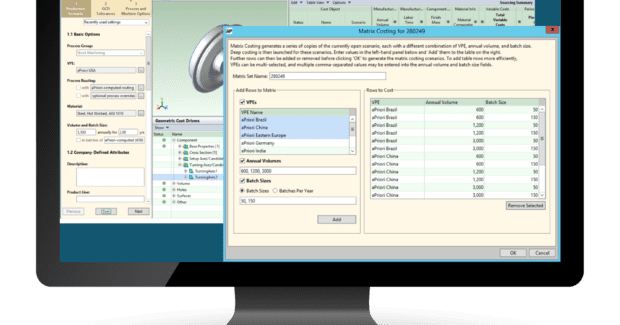

At some point, though, aPriori realized its software could benefit another user: the outside companies. Moreover, the software could be tailored to duplicate an outside company’s specific manufacturing capabilities, creating what aPriori calls ‘a digital factory.’

And the practical benefit of the software to contract manufacturers? “If we could help them quote faster but still quote very accurately, this could increase their win rate,” Feraday said.

As an example, she cited a large contract manufacturer. The supplier had become an aPriori customer and had used the software to create a digital factory. The company, which makes sheet-metal parts, then used the factory to generate quotes in response to RFQs.

“Before using aPriori, they would win about 15 to 20 percent of the RFQs they responded to,” Feraday said. “After using aPriori, that win rate went up to 68 percent.”

IN DEVELOPMENT: DIGITAL COLLABORATION

aPriori is working on a suite of cloud-based programs that would allow buyers and suppliers to collaborate more closely. Right now, through aPriori software, they can share a significant amount of manufacturing data during the bidding process. That way, buyers can minimize their part costs and suppliers can maintain their profit margins.

Beyond this data collaboration, the in-development software would allow for what aPriori calls ‘digital collaboration.’

Feraday said that in a digital collaboration, a company’s design engineers, manufacturing engineers, and sourcing people would be able to digitally collaborate and interact with questions on a CAD model or on an estimated cost and have workflow to guide them through those interactions.

“The same thing is true for the interaction between a buyer and a supplier,” Feraday said. “Kick off a process to request for a quote, but enable a digital collaboration where if they [suppliers] receive a CAD model, they can ask questions about it before they generate their quote. Or if they get an aPriori should-cost [estimated cost], they can ask questions about different elements of that as it relates to the buyer’s preference, the buyer’s desire to drive certain outcomes in certain directions.”

Feraday said the ultimate goal of this aPriori work is: “To be able to create a traceable, efficient digital interaction.”

“This technology is in development,” she added. “It’s not on the market yet.”

IT ALL STARTED WITH AN INTERN

aPriori’s suite of programs started many years ago, with a grad student during an internship with a company that made agricultural equipment.

During the internship, the student noticed a problem with a number of the company’s cost estimates. “As the design engineers were designing products, they were bringing them to market above the cost target,” said Stephanie Feraday, CEO of aPriori. She added that back then, the design engineers had trouble preventing cost overruns because: “They didn’t have any way to get really quick, insightful feedback for them to be able to do anything about it. There were cost experts on hand, but because calculations were so manual, it might take a few days to a week—or a couple of weeks for something complex—to give them feedback.”

Feraday continued, “And by then, the design engineers have moved much further along in the design process. So, there wasn’t an effective way to give the design engineer that immediate guidance to help him understand the ramifications of his design choices.”

So, from the start, aPriori software was intended to create quick, accurate cost estimates, specifically by automating the process. With cost experts generating estimates faster, design engineers could get the fast feedback they needed to know how their design choices were affecting their cost targets.

“That was the original premise,” Feraday said.