New Advances Make Adaptive Control of Resistance Welding i4.0-Ready

New welding quality analytics packages for the automotive manufacturing industry offer expanded real-time analysis and process improvement for welding operations.

Posted: January 31, 2022

The 21st century automotive market is undergoing some of the most dramatic and intense changes in its history. These changes go beyond the vehicles themselves: Automotive OEMs are aggressively implementing Industry 4.0 (i4.0) capabilities into their manufacturing platforms — leveraging advances in communications protocols, new controllers and cloud computing for real-time data capture and analytics.

One of the most critical automotive manufacturing processes is high-speed automated welding. A new generation of advanced, i4.0-ready adaptive resistance welding controls is now available to help deliver a broader range of critically needed welding control capabilities, including faster commissioning, better precision and process flexibility and more productive welding operations. In addition, new i4.0 weld analytical tools are being introduced to help provide real-time, actionable information that can further improve weld quality and operational efficiency.

New challenges lead to improved adaptive resistance systems

Robotic resistance welding is a high-speed, cost-effective way to rapidly weld hundreds of parts per hour. Using cutting-edge processor platforms, adaptive control takes into account precise functional welding characteristics, such as current, voltage and resistance, to perfect each weld. These characteristics are monitored by the welding control system on a millisecond basis, constantly comparing them in real time against a master resistance curve that controls the quality of the process.

One of the most significant new challenges for adaptive resistance welding control comes from an increased use of high-strength steel, aluminum and next-generation materials in vehicle bodies and parts, replacing mild steel and other metals.

The core of adaptive resistance welding control is having the capability to adjust the quality of the weld within a millisecond time frame. With this capability, key values (e.g., current, voltage, force, time, resistance and phase angle) can be manipulated to overcome some of the newer challenges related to the expanded use of aluminum and other materials.

Leading technology suppliers have launched a new generation of resistance welding platforms able to read the expansion of aluminum due to heat and can adapt to this data. This is done by calculating the data from the expansion of the welding gun tips and then regulating the weld through current and time. As a result, this important capability can help give automotive manufacturers an advantage in their manufacturing operations.

New technology increases welding flexibility and control

There have also been developments in resistance welding systems that expand the number of heat blocks available so that welding system programmers and technicians can fully customize the current waveform for each weld. Until recently, automated resistance welding platforms typically supported three heat blocks: the pre-weld, the weld itself and the post-weld.

While effective, having only three heat blocks did not give welding operations the full ability to create more sophisticated welding sequences that could respond better to minute variations in the parts being welded, such as specialized coatings, poor fits between two parts being welded or changes in the amount of carbon or other trace alloys in “new steel.”

Recently, Bosch Rexroth introduced a new resistance welding platform, the PRC7000 welding control, that addresses these limitations. The PRC7000 can store up to 10,000 welding programs that, through a user-friendly drag-and-drop interface, support more sophisticated welding sequences that can have 100 or more separate heat blocks.

For example, a particular weld for a higher-strength steel might need a pre-weld at 30,000 amps to heat the steel for 30 milliseconds, then a long transition to a higher force with a lower current for 500-to-600 milliseconds to contain the material. Each part or each type of material can now have more dynamically designed welds so that manufacturers have much greater freedom to control and improve welding results.

Industry 4.0 capabilities and Weld Spot Analytics

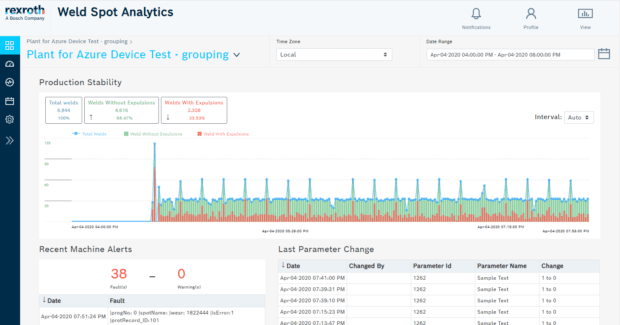

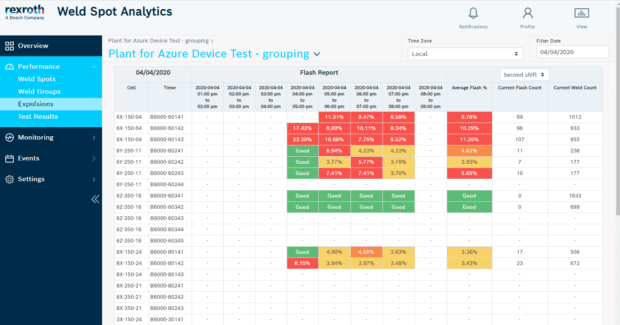

There are also new welding quality analytics packages being made available to the industry, offering an expanded level of real-time analysis and process improvement for welding operations.

Until recently, it was up to car manufacturers to download welding data and incorporate it into their own analytical tools. These new packages automatically compile weld spot data into easy-to-read formats and dashboards. Operations personnel can configure their dashboards to monitor their day-to-day responsibilities as well as more long-term process analysis. It can also send real-time automatic SMS alerts to welding operators who can take steps to correct issues and ensure maximum welding uptime.

These analytics packages are designed to help welding engineers make faster, more accurate decisions that increase weld quality while avoiding inefficiencies such as parts reworking. That same data can then be correlated to other factors, such as part fit-up or secondary circuit degradation, to help production management more rapidly identify the root cause of electrode wear and take appropriate action.

Greater intelligence added functionality for custom heat blocks and welding sequences, easier integration plus real-time actionable data are just some of the i4.0 capabilities these new platforms offer, helping automotive manufacturers enhance the flexibility, quality and repeatability of their welding operations.

. Learn more at www.boschrexroth-us.com