Going Beneath the Surface with Vapor Degreasing

Cleaning is an essential step toward achieving a quality surface finish. Vapor degreasing offers long-term flexibility and adapts to specific requirements, among other advantages.

Posted: January 30, 2022

SMOOTH OPERATIONS

By Elizabeth Norwood

Good surface preparation determines the success or failure of subsequent processes like painting, coating, plating or welding. To achieve a quality finish, cleaning is key. Even the smallest amount of contaminant can negatively impact the finished product’s performance or detract from the part’s final appearance.

What Contamination?

Initially, manufactured components may look clean, but upon closer inspection, that may not be the case. Metal parts often have a wide variety of contaminants left on them that can interfere with final finishing methods. Machining oil, lubricants or polishing pastes are typical contaminators. Other production residue like adhesives, wax, marking inks, fingerprints and dust are also common.

The location of the contaminants on the parts is what often makes metal parts cleaning difficult. Dirt and debris are not only left on large flat areas that are easy to clean, but also in the hidden, tiny crevices and internal blind holes that are difficult to reach. Some components are extremely complex in shape with intricate geometries and awkward profiles making getting to the contaminant and cleaning it successfully even more of a challenge. There is however a solution to a ‘complete clean;’ vapor degreasing.

The Answer to a Successful Finish

Vapor degreasing using modern, highly advanced cleaning fluids makes parts cleaning simple, consistent and sustainable. It results in a high-quality, pristine surface that is ready for post-machining processes.

An optimal metal cleaning process should successfully dissolve or displace contaminants without damaging substrates, and leave surfaces dry, spot-free, and ready for the next stage of production. Vapor degreasing ticks all these boxes and more.

Vapor degreasing uses cleaning fluid immersion, followed by vapor rinsing and drying, to thoroughly clean metal components. It removes all types of contaminants, from the toughest oils and polishing compounds, to heavy particulates such as dust and metal fines.

It is not only fast and efficient but it has a high throughput and can be easily automated into standard production lines, allowing manufacturing to smoothly continue without interruption.

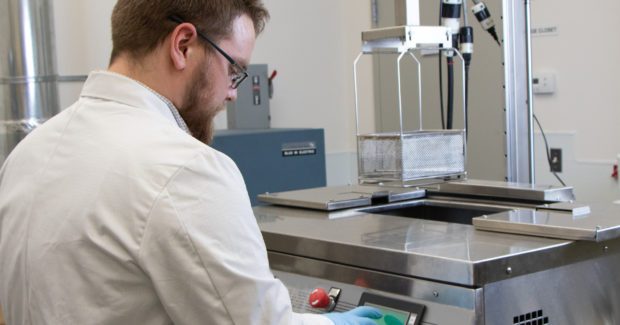

A vapor degreasing machine is a closed-loop system that uses a specialized low-boiling, non-flammable fluid as the cleaning agent. Most systems are comprised of a top-loading batch-style cleaning machine with a boil sump and a rinse sump. Contaminated parts are immersed in the boil sump to dissolve or lift the soils from the surface of the parts. Once cleaned, the parts mechanically transfer to the rinse sump. The parts rinse in pure, uncontaminated fluid or inside the fluid vapors themselves. In some cases, ultrasonic agitation can be added for extra cleaning power.

After a typical cycle of about six-to-20 minutes, the metal parts come out clean, completely rinsed, dried, spot-free, and ready for the next step in the process, whether that’s assembly, further finishing treatments, labelling or packing.

Cleaning Fluid — the Silver Bullet

What makes vapor degreasing so successful at effectively cleaning metal parts is not just the vapor degreasing machine itself, but also the cleaning fluid used within it. Advanced cleaning fluids make parts cleaning simple, safe, consistent and sustainable.

- Cleaning Power

Modern cleaning fluids have many chemical properties that are beneficial to critical cleaning and surface preparation. They typically have low surface tension and a very low viscosity, allowing them to easily penetrate and clean even difficult spaces like inside end holes on the smallest of parts. Most vapor degreasing fluids also are very heavy and dense, which aids in dislodging heavier particulate from the components. Even more importantly, the cleaning fluid evaporates and dries completely from both inside and outside of the parts without leaving any contaminants or residue behind. This is especially helpful when cleaning materials prone to flash rusting.

There are many vapor degreasing fluids on the market so it is important to choose one that will work effectively for the contaminant that needs to be removed. When it comes to precision cleaning “like cleans like.” For example, if a nonpolar contaminant like oil requires removal, a nonpolar cleaning fluid should be matched to remove the contamination from the metal part.

Importantly, modern cleaning fluids are lab-tested to ensure the cleaning results are reliable and consistent. They are usually formulated using a mixture of ingredients. For example, hydrocarbons including mineral spirits, or alcohols like isopropanol and ethanol. The combination of ingredients determines the cleaning fluid’s effectiveness and its material compatibility. The vapor degreaser can use a single cleaning fluid or fluids can be mixed, blended or custom engineered to remove a specific soil from a specific substrate to maximize cleaning effectiveness while minimizing any surface damage.

- Environmental Benefits

Sustainable manufacturing is important in all workshops, and manufacturing metal components in an environmentally friendly way should be a top priority. It is not only beneficial to the environment, but it also has implications on worker health and safety, regulatory compliance and financial advantages.

Implementing sustainable cleaning practices will not only increase operational efficiency by reducing waste and costs but also improve the quality of the end product.

An important point to note when it comes to modern vapor degreasing fluids is their outstanding green credentials. Most have a very low GWP (Global Warming Potential) and a zero ODP (Ozone Depleting Potential) to help reduce greenhouse gas effects and meet strict air quality regulations.

Many are not considered a HAP (Hazardous Air Pollutant) with some of the newer fluids based on new HFE (hydrofluoroethers) or HFO (hydrofluoro-olefin) technology. This makes them excellent replacements for nPB (N-Propyl-bromide) or TCE (trichloroethylene) that cause air and groundwater quality concerns. This means the newer cleaning fluids meet with many directives including U.S. EPA regulations and European F-Gas and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation. What makes these innovative cleaning fluids even more impressive is that they offer improved environmental properties without compromising the performance.

Another environmental boost for vapor degreasers is their capability for continuous recovery and recycling. The cleaning fluid is used many hundreds of times before it needs refreshing or replacing. When that time does finally come, the vapor degreaser concentrates the soil and contaminants, minimizing the waste generated and frequency of disposal.

- Helping Keep People Safe

When it comes to using a vapor degreaser, the environmental benefits are clear. So too are the health and safety advantages for the operators. Advanced vapor degreasing cleaning fluids are non-toxic and have excellent safety profiles. Plus, they are non-flammable, eliminating any fire risk.

The PEL (Permissible Exposure Limit) or OSHA-designated time limit for worker exposure to a cleaning chemical is much better for the newer, sustainable cleaning fluids. Higher numbers indicate a safer fluid. Typical permissible exposure levels for the newer, sustainable fluids are about 200-to-250 ppm (parts per million). Whereas TCE has a 100-ppm PEL and nPB is rated at only 0.1- ppm. In addition, sustainable metal cleaning fluids are approved under the U.S. Significant New Alternatives Program (SNAP) and Toxic Substance Control Act (TSCA).

- Easier on the Wallet

The cost savings when using a vapor degreaser and newer cleaning fluid are impressive. The first point to make is in most cases modern cleaning fluids can be used in existing vapor degreasing equipment. Once the system is emptied and cleaned, the replacement fluid is “dropped in” to the machine with small or no modifications. This means there is little disruption to production workflow and no re-training of operators on the use of a new process.

Because the cleaning fluid is recycled and reused over and over again there is nominal cost in frequent fluid replacement. Additionally, the cleaning fluids do not require the stabilizers, scavengers or weekly acid acceptance testing required of legacy brominated or chlorinated solvents, reducing overall maintenance costs.

Future Success

Cleaning is an essential step within the fabricating and metalworking environments to achieve a quality surface finish. Without it, performance and reliability of finished parts may be compromised. Finding a cleaning method is easy but finding one that ticks all the boxes required for successful manufacturing can be more challenging.

Using a vapor degreaser and modern sustainable cleaning fluids gives manufacturers the cleaning power to remove contaminants successfully, yet is gentle enough not to affect the part itself. It cleans small and complex parts, ensuring all surfaces are clean. Vapor degreasing also has long-term flexibility thanks to its capacity to adapt to specific cleaning requirements. It is environmentally sustainable, worker safe and complies with regulatory standards placed on many metal fabricators today. It is also a consistent and automated high-volume cleaning process that is less labor intensive, which saves both time and money. This helps boost production throughput and allows manufacturers to meet demanding deadlines. www.microcare.com