Five Things You Need to Know About Connected Machine Monitoring

There are numerous advantages to implementing machine monitoring platforms. Start small and zero in on data that identifies pain points so your shop can make the changes needed to optimize goals.

Posted: January 30, 2022

DIGITAL BY DESIGN

By Cory Carpenter

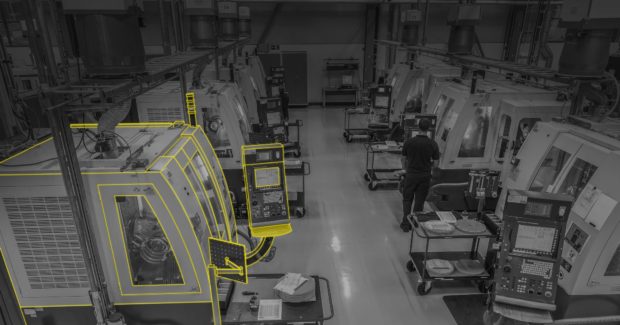

Digitally connected machining is following the Industry 4.0 transformation other industry segments are undergoing. One of the most important advantages of that transformation is the data that connected machines can provide in real time. This real-time data offers machining operations new possibilities for transparency, optimized planning and more streamlined, error-free production.

However, data alone is not enough — and often can be too much. In our Fabricating & Metalworking article in June-July 2021, “Five Things You Need to Know About Smart Manufacturing,” we examined how digitally connected machines can help provide the data needed to make better decisions in real time. In this article we’re expanding on that topic to discuss the best methods and tools to mine, organize and analyze connected machine data to help implement continuous improvement and lean manufacturing.

1. Machine analytics is more than green/yellow/red andon lights.

When machine shops depend on the green, yellow or red andon lights to indicate the status and utilization of their operations, they’re not making the best use of the data their machines are generating. If you see a red light, what is that telling you? Has the machine crashed? Is engineering doing a test, or is the machine out of work material?

Some companies will have in-house analytics that take historical data exported from machines to assess processes after the fact. However, the latest generation of connected machine monitoring systems provides real-time, in-depth analytics that capture and report the data underlying those red, yellow and green lights. That data is based on rules established in collaboration between the condition monitoring software provider and the machining operation. These rules can follow industry-standard measurements for overall equipment effectiveness (OEE), incorporating factors such as machine utilization, availability performance and production quality. These platforms are designed to capture and report the kind of data machining operations have determined to be crucial to sustain continuous improvement and lean manufacturing efforts.

2. Start small and focus on capturing and analyzing data from specific machines or processes.

So, you have a lot of machines generating a lot of data — how do you determine what data to focus on to make the best use of powerful condition monitoring software? Apply classic lean principles to start. Identify persistent issues or bottlenecks — waste, unscheduled downtime, quality issues with specific parts or machines — that you need more complete data on to implement root cause analysis.

For example, many shops find that they have machines that spend more time doing setup than actually machining parts. The right condition monitoring software can be configured to track key parameters: setup times, part loading/unloading time, time spent on fixture changes, tool changes, or blow-off cycles, etc.

Today’s machining condition monitoring platforms let you easily configure and track these data points and zero in on where time is wasted and contributing to low utilization of your assets. More importantly, this data is now available in real time and is much more accurate, which equips you with the data to make operational changes or business decisions much more rapidly and with confidence that you will achieve your optimization goals.

3. Classify the data you track to guide meaningful business decisions.

In lean manufacturing continuous improvement processes, the first step is often to ask operators on the shop floor about what’s going on — what are their pain points and persistent issues. With today’s condition monitoring software, we can now start collecting dynamic input from ongoing operator input to identify patterns. In addition, we can directly ask the digitally connected machines what’s going on — eliminating the need to manually monitor machines with a stopwatch and spreadsheets.

An important step is to classify the data the system captures into categories that can drive meaningful business decisions. For example, you could focus on a machine or group of machines and find out how much time was spent cutting a specific part. Further analysis could identify which part or parts caused the most unscheduled downtime on those machines.

Comparing the most optimized machines running that part with other machines can enable decisions around how different machines are scheduled, improve maintenance or replace tooling on machines with too much downtime or determine that additional capacity may be needed.

4. Choose condition monitoring platforms from providers with machining expertise.

There are a range of commercially available condition monitoring software platforms available, many developed for general industrial applications. CNC machining and machine centers are highly specialized systems with unique operating factors that may require significant customization of off-the-shelf software to generate actionable, real-time data applicable to common machining utilization and quality manufacturing challenges.

There are advantages to selecting a platform created by a manufacturer that has in-depth machining expertise — especially one that is using that same platform to continuously improve their own operations. Platforms from these suppliers are already configured to capture, organize and analyze machining data, eliminating the need for extensive configuration and saving valuable time when you begin using them.

Manufacturing companies such as Sandvik Coromant that supply high-quality condition monitoring software also offer valuable technical support — both remotely and/or, onsite. Furthermore, they can also continue the partnership walking hand in hand with the improvement efforts offering their expertise in manufacturing knowledge in support through the whole process.

Sandvik Coromant has found that customers utilizing its CoroPlus® Machining Insights platform were able to realize quick returns on their investments (in many instances less than three-to-six months). This pay back typically comes from the initial improvements efforts of reducing waste in their processes from the insights the software can offer. Mainly because the average shop typically, and most often unknowingly, operates at a 30-to-40 percent utilization of its assets.

A key factor to consider when selecting condition monitoring platforms is the design and ease of use of the operator dashboards they offer. Well-designed dashboards provide critical visual metrics and alerts on the key indicators you establish to assess machining performance. This real-time data about when a machine is running and not, stop causes, faults and alarm reasons enables operator and engineering intervention to prevent issues from becoming serious problems. These dashboards also provide insights into opportunities to improve resource planning, asset management and cost and time prediction.

The best platforms support drag-and-drop programming, built around the key tasks, processes and performance metrics unique to machining, for easier setup and enabling you to customize the dashboards to your needs and workflows. They should also support tablet and smartphone displays so operators can receive alerts and respond to issues without having to go to specific machines.

5. Cloud-based condition monitoring systems offer inherent advantages.

Condition monitoring platforms that are cloud-based offer multiple advantages compared to systems that must be installed and networked on servers at your operations. Many of the more recent machine tools have high-speed Ethernet-based interfaces that make it much easier to connect tools and production floors to external networks with access to cloud-based applications.

The kind of complex, real-time analysis and reporting provided by these condition monitoring programs utilize advanced algorithms and significant processing power — which the cloud is much more able to support than on-premise servers, no matter how robust. Not to mention, solutions that are cloud based such as Machining Insights, offer operators not only the ability, from literally anywhere in the world, to view the current state of their machines but also how those machines have performed since the first day they were connected.

With a cloud-based solution, data is protected behind firewalls, with leading condition monitoring providers offering systems that typically comply with strict government security protocols covering sensitive defense and intelligence applications. A cloud-based application is managed and kept up to date by the platform provider. This means that machining company IT departments are not required to maintain expertise in managing and updating this kind of application.

One further advantage is that cloud-based condition monitoring programs can be rapidly implemented without any additional hardware, with the same system supporting multiple locations worldwide. They also can support remote support capabilities, enabling technicians to collaborate with end users on a specific machine issue and implement the solution over the network.

Cory Carpenter is a digital machining specialist at Sandvik Coromant. Email [email protected]. Learn more at www.sandvik.coromant.com.