3D Printing Is Helping Transform How Everyday Life Is Built

Additive manufacturing is producing complex, high performance tooling and components that go the distance in the most demanding applications.

Posted: January 27, 2022

From the vehicles we drive across town to the energy facilities that power our daily lives, additive manufacturing is increasingly shaping the tools and components used to build the world around us.

As end markets such as aerospace, energy and automotive evolve and advance, they require new approaches to machining parts and manufacturing wear-resistant components. Additive manufacturing (AM) — or 3D printing — is a key innovation-enabling technology because it offers a huge opportunity to improve performance and deliver value for end users.

The advantages enabled by AM include: lightweighting with strength, complex geometries not possible with traditional methods and shorter lead times — all of which enable users of 3D printed tools and components to run longer, cut faster and machine with greater efficiency and cost-effectiveness.

Lightweighting

Take the automotive market. As OEMS rapidly expand their hybrid and electric vehicle offerings, additive manufacturing is helping to meet growing demand for the lighter weight tooling solutions needed to machine e-vehicle components, such as the stator housings of electric motors.

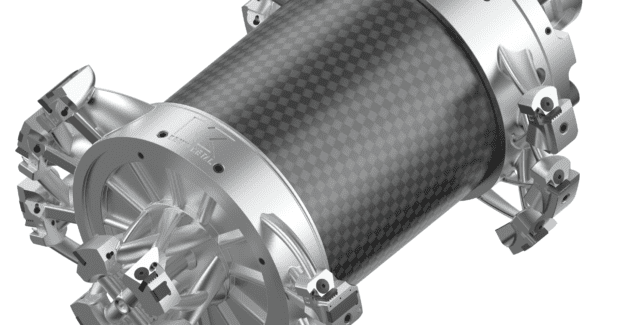

An example is Kennametal’s 3D-printed stator bore tool, which combines a carbon-fiber-body and our proven RIQ inserts technology to deliver unmatched productivity and reliability in the production of large diameter, deep bore electric motor housings.

The stator bore tool weighs approximately half that of a conventionally manufactured version, enabling auto manufacturers to utilize it on their existing high-speed machining centers as they change over lines for electric vehicle manufacturing.

Machining three diameters in one operation, the tool ensures the alignment and concentricity of the machined surfaces while significantly reducing cycle time. It enables a faster tool change and spin-up even on less powerful machines. And surface specifications and component tolerances are achieved without constraints, while hassle-free chip removal is ensured by means of the wing-like arm design.

Design Freedom

Additive manufacturing also enables extraordinary design freedom, which in turn enables better performing tools and components. With 3D printing we can put material only where we need it to produce complex geometries that would be difficult or impossible with traditional manufacturing methods.

For example, Kennametal turned to laser powder bed additive manufacturing to solve the challenge of how to produce tiny coolant channels in the smaller diameter standard tool holders in our KenTIP FS modular drill portfolio. These channels push coolant through the tool holder to lubricate the insert and evacuate chips. With AM, Kennametal was able to extend the through coolant feature to drill diameters as small as 6 mm — enabling customers to leverage the improved performance and cost-savings of the modular system in a broader range of applications.

Another example is the HiPACS drilling and countersinking system for aerospace fastener holes. Designed to drill and chamfer holes in one operation, the high-precision tool meets the aerospace industry’s stringent accuracy requirements, while delivering increased tool life in machining aircraft skins. A key benefit of the system is that it works with any Kennametal standard hydraulic chuck thanks to a unique combination of 3D printed slots and pockets — features that would be too large and/or cost prohibitive to manufacture conventionally.

Shorter Development and Lead Times

In addition to design freedom, AM also has the potential to shorten development cycles and manufacturing lead times. Taken together, these benefits make AM an attractive technology for customers in many markets, including those where the cost of downtime is very high, such as oil and gas.

In these applications, it’s the combination of materials science and manufacturing expertise that unlocks the full value of additive manufacturing. Tungsten carbide and Stellite™ materials have a long legacy of excellent wear and corrosion performance in some of the world’s most demanding environments. Kennametal is combining its expertise in these and other wear-resistant materials with the power of additive manufacturing to produce complex, fully finished components that go the distance in demanding energy applications.

Many of these production components are already in service or being tested in the field. For example, to help a customer beat long lead times for a critical refinery component, Kennametal 3D printed the part from its proprietary Stellite 6 AM™ material. Leveraging binder jet printing, Kennametal delivered the component in one-fifth the lead time of the cast component. The part is currently undergoing a two-year field test.

In another case, an oilfield services provider designed a flow control device featuring flanges, internal geometries and elevation changes that would significantly improve performance — but also would have required a prohibitively lengthy development cycle using traditional manufacturing techniques. Kennametal combined its proprietary tungsten carbide metal powder with binder jet 3D printing to achieve the desired geometries and deliver improved wear performance over the prior steel version. The part was delivered ahead of schedule and is in service in the field.

End-to-End Capabilities

3D printing can help make better performing parts, faster. And those products in turn help customers be more productive and cost efficient. But AM is also complex — you can’t just add powder and press print. There is a tight interdependency between materials, design and manufacturing expertise needed to produce high-performance, repeatable AM tools and components.

Materials drive property improvements as much as equipment. Composition, particle size, shape and distribution all impact material properties and the ability to produce repeatable 3D printed parts. Kennametal is tailoring tungsten carbide, Stellite and other wear resistant materials specifically for additive manufacturing processes, such as its new Stellite 21 AM™, the first Stellite powder qualified for laser powder bed additive manufacturing.

Post-print processing capabilities are also important because they can account for a significant portion of production cost and have a critical impact on the performance of the part.

That’s why an end-to-end approach is so critical. In addition to deep expertise in material science, powdered metal, advanced product design, and 3D printing technologies, Kennametal is leveraging a strong foundation in post-print capabilities — including sintering, hot isostatic pressing and finishing.

Taken together, these capabilities are producing innovative 3D printed solutions that transform how everyday life is built.