More and More Magnets: Industrial Magnetics Inc. Expands its Reach

IMI has expanded through the years by increasing the variety of its products, by entering additional industries, and by acquiring other companies, including Walker Magnetics.

Posted: December 28, 2021

SUPPLIER PROFILE

By Joe Hazelton

The Covid-19 pandemic has curtailed the social lives of people and lowered the productivity of companies. But, it hasn’t brought them to a halt, not permanently. People find ways to safely get together with their families and friends. Likewise, companies find ways to cope with challenges and continue their work.

One of those companies is Industrial Magnetics Inc. (IMI) of Boyne City, Mich. “We’re feeling the same stresses of the supply chain that everybody is right now,” said Dennis O’Leary, chief business development officer for IMI. “That’s one of the toughest challenges for us.”

O’Leary explained that IMI generally processes about 15,000 to 16,000 unique purchase orders every year and that it has an on-time delivery rate of about 98.5 percent. IMI’s rate has been reduced by the global supply chain problems, but the company is still working to complete its orders as soon as it can. And, despite those problems, IMI is still expanding its business.

EXPANDING ITS REACH

“We’re just completing this 36,000-square-foot addition to our manufacturing space, which is going to accommodate the acquisition of Walker Magnetics,” O’Leary said.

The acquisition is a little more than a year old. In September 2020, six months after the pandemic came to the United States, IMI bought Walker Magnetics of Worcester, Mass.

“It was an incredible opportunity for us,” O’Leary said. The opportunity was to buy a company with magnetic products that complemented IMI’s own products. “They manufacture product that exists in a lot of the same places where you find ours,” O’Leary said, “but on more of the heavy lifting, scrap-material handling and workholding side than we’ve ever had as part of our lineup.”

In addition to acquiring Walker’s assets, IMI managed to retain the entire sales and engineering staff. “They came with a very experienced engineering and sales staff who we’ve been able to keep intact,” O’Leary said. “Basically, everybody that the prior owner would allow us to hire, we hired.

“We’ve got them in several locations,” O’Leary continued. “The engineering staff is in Worcester, Massachusetts, which is where the company was founded. And then with some of the sales in roles as regional managers, they live in the regions for which they’re responsible. We have a sales and product-line management staff in Columbus, Ohio, which is where one of the factories was before we moved it up here. But, talent retention has been good, and that’s a tough thing right now, so we’re happy to have them onboard.”

O’Leary expected IMI to finish absorbing Walker by the end of October 2021. At that point, in Boyne City, the addition to IMI’s factory would be completed and would be filled with Walker equipment.

IMI has bought companies in the past, and O’Leary expected IMI would keep an eye out for other companies in the future. “We’ll continue to look at acquisitions that can help us grow our company,” he said. However, he pointed out that acquisitions: “They’ve got to be meaningful. It’s got to fit in with who we are, how we manufacture, how product flows through our value streams in the shop, and if it makes sense.”

Besides growing through acquisitions, IMI has grown naturally by widening its customer base and expanding its product offerings. “We had a narrower market focus when I started back in 1999,” O’Leary said. “So, the customer base has changed. When I arrived, the focus was food and mining and automotive, and the MRO business.”

IMI had customers in those four industrial spaces but was limiting itself. “We built some very unique product that was extremely application specific,” O’Leary said. “We wouldn’t utilize that product to build out the space. We would just hold that drawing for the next time that customer may have called us in a couple of years.”

Said O’Leary, though, IMI realized that in whatever industry its product was, it was “very much a utility product.”

That utility suggested how IMI could change its approach 1) to the market spaces where its products already were and 2) to many other market spaces. O’Leary described the original approach as: “Well, we’re just going to make this for this customer.” He then described the new approach, which started with IMI asking itself a question: “Well, if this customer can use that product, how many more prospects are in a given market space that could benefit from having this same or similar product?”

“We did that time and time and time again, and that really drove the direction of the company, from being driven by the market to really attempting to do our best to drive the market in the direction that we desired,” O’Leary said.

Today, IMI serves many additional markets, such as feed and grain, furniture, HVAC, milling, petrochemical, pharmaceutical, sheet metal, and stamping.

As for expanding its product offerings, O’Leary cited IMI’s lineup of Transporter products: “On the material-handling side, the Transporter products has largely been our most successful single product family. It’s magnetic, end-of-arm tooling that we introduced in the year 2000. You will literally find this magnetic tooling in hundreds and hundreds of plants in different applications.”

Given such expansion, IMI is much larger than it was when O’Leary joined the company in 1999. “Through our organic growth as well as several acquisitions we’ve made since 2014, we’ve gone from 70 to 125 employees,” he said.

Two acquisitions still have facilities separate from IMI. “Everything else we’ve acquired has been absorbed up into our headquarters here in Boyne City, Michigan,” O’Leary said. “So, since 2016, we’ve added 54,000 square feet of manufacturing space onto our facility up here to accommodate that growth.”

A CLOSE-KNIT COMPANY

O’Leary formed his first impressions of the company during the interview process, when he was introduced to the organization. “I found the company to be—it appeared to me—to be close-knit and almost family oriented,” he said. “It’s lived up to that expectation.”

IMI is involved in local activities in Boyne City and its surrounding communities, where much of the company’s workforce lives, activities such as adopt-a-highway campaigns. It also supports trade schools and supports shadowing internships for young people interested in being welders or fabricators. And all of this activity occurs in an area that is, in essence, an outdoor playground. (See SET IN AN OUTDOOR PLAYGROUND below.)

IMI is also involved in giving to local charities. “In the last 10 years or so, we’ve donated $17,000 to local charities, a broad range of charities,” O’Leary said. “Every quarter, one of our employees manages our one-dollar, Friday-jeans-for-charity can. And, then, that money is gathered at the end of the quarter and given away to a local charity.”

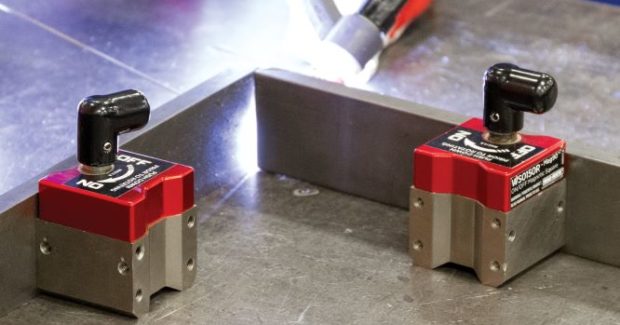

HEAVIER LIFTING, MORE AUTOMATION

With the addition of the product lines from Walker Magnetics, IMI expects to provide its products to more applications that involve heavy lifting such as plate steel that measures several feet by several feet: “Four by eight, half-inch piece of plate steel, so hundreds and hundreds of pounds,” O’Leary said.

IMI also expects to see “what we would call ‘automated material handling,’” O’Leary said. “Probably both in the short and the long term. Less manual lifting, pulling, bending, twisting movement of parts, and moving more into automated phases, robotic applications.”

O’Leary added that he expected industry to keep using automation more and more because: “We have such a gap, such a labor gap. I don’t see us overcoming that as a nation anytime soon, so I think it’s just going to continue down that road to automating material-handling processes.”

TURNING TO MAGNETS

O’Leary said IMI’s biggest success stories involve companies that switch from manual material handling to magnetic material handling. As an example, he referred to material handling in the production of armor-plated vehicles, to the company’s loading, machining, and unloading of quite large pieces of plate steel.

“This is an application where the prior loading mechanism was welding lifting lugs to a massive piece of 10-by-20 plate steel and then loading it onto a cutting table and then individually unloading the parts—very heavy, very cumbersome, and dangerous parts—manually with lifting lugs and slings and chains,” O’Leary said.

When the customer switched to magnetic material handling, then its loading and unloading became a bit different. “The magnet basically went over the top and lifted up the entire piece of plate steel onto the cutting table,” O’Leary said, “and then could unload the entire skeleton and cut parts in an automated fashion.”

And how much did throughput increase by? “By four times,” O’Leary said. “That’s an application we’ve done numerous times.”

Naturally, an increase in throughput can lead to an increase in efficiency. Besides those two goals, though, magnetic material handling can decrease injury or risk of injury.

“Parts come into most every plant in big gaylords,” O’Leary said. “Your operators are constantly leaning down, bending over, or pulling out all sorts of heavy, odd-shaped parts. If we can minimize or eliminate that by putting a magnet on the end of some sort of a pick-up tool and make it an automated mechanism, then everyone wins. Everybody who’s ever had a loss-time accident or workers’ comp claim knows what that can save.”

So, IMI looks for its products to achieve three goals with customers: increase throughput, increase efficiency, and decrease injury or risk of injury. “Those are the calling cards when it comes to using magnets for material-handling applications,” O’Leary said.

However, safety can extend to not just IMI’s customers, but also to their customers’ customers. (See MAKING METAL-FREE FOOD below.)

SEEING MAGNETS

O’Leary said that once customers see magnets used in one manufacturing application, they start to see how they could be used in other manufacturing applications. He added that customers start wondering how they could use magnets in their own operations: “‘What if I tried it for this, and tried it for that, and tried it for that?’”

Naturally, in the right application: “Magnets are a fantastic alternative,” O’Leary said.

SET IN AN OUTDOOR PLAYGROUND

Founded in 1961, IMI started out in Ferndale, Mich., a suburb of Detroit, where the company served the automotive industry.

However, IMI’s founder, Mike Stowe, liked downhill skiing and boating. And his favorite locale for both activities? Northern Michigan, specifically Boyne City and its surrounding area.

“He always liked to come up here to ski or boat—like a lot of people do,” said Dennis O’Leary, chief business development officer for IMI. “So, he decided at one point: ‘You know, I’m going to move the company up there.’”

So, in the late ’70s, Stowe started to transition IMI up to Boyne City. O’Leary described it as “a pretty bold move.” For starters, Stowe had to find new staff for his relocated operation. Once the company settled in, though: “It’s been here ever since,” O’Leary said. “It was a great decision.”

And Stowe’s attitude—Boyne City as outdoor playground—is shared by a number of IMI employees. The company’s facility is just three miles from Boyne Mountain, a ski resort. “We have quite a few of our staff that, at lunch time, will run to the mountain and ski for a half-hour and come back,” O’Leary said.

MAKING METAL-FREE FOOD

The food-processing industry is an example of how Industrial Magnetics’s concern with safety can extend to its customers’ customers. Like many industries, food processing uses magnets for material handling, but it also uses them for decontamination.

“We’re trying to extract metal contaminants from something that you and I are eventually going to ingest,” Dennis O’Leary said.

The contaminants can be very small, such as fines; they can get into a product’s ingredients, like sugar, flour, or cocoa; and they can therefore be very difficult to see, much less remove. “We want to get metal out of all that before it turns into a Pop-Tart or a granola bar that you buy on the shelf and eat,” O’Leary said.

By getting contaminants out during production, companies keep their customers safe and avoid recalls. “You see the product recalls,” O’Leary said, “foreign substances in cakes or cookies or candies or ice cream. It can often be a brand killer.”

Joe Hazelton is an editor with Fabricating & Metalworking. He can be contacted by emailing [email protected].