Another Dimension to Flat Sheet Laser Cutting

The ability to perform edge contouring on flat sheet cutting lasers makes laser cutting even more flexible as a fabrication tool.

Posted: December 30, 2021

THE CUTTING EDGE

By Tom Bailey

There’s no question, the 2D laser-cutting machine is the king of flexible metal fabrication. While many technologies can cut metal parts from raw sheet stock, none of them approach the application range or productivity of the laser.

From foil thickness to heavy structural plates; from simple rectangles to absurdly complex shapes; from rounded discs to sharp saw-teeth; the laser machine can tackle all these cutting jobs with unmatched speed and precision, and even engrave part numbers on the product to boot.

Still, despite how commonplace laser cutting has become in manufacturing, and even though shops of all kinds depend on laser cutting as their primary workday tool, this technology still comes with one noticeably clear limitation.

Laser-cutting machines are designed to cut flat sheets normal to the surface of the material, or put another way, they are intended only to create two-dimensional cuts. While in many sheet metal applications this is no limitation at all, there are other jobs that require cut features like edges and holes to be contoured in three dimensions. Thicker parts that will be welded into an assembly may require beveled edges to allow for better welding properties. Holes might need a countersink to accommodate a fastener. Part edges that will be handled frequently need to be rounded off to reduce risk of user injury. All these situations will require those two-dimensional laser-cut parts to be additionally processed after cutting is complete, adding cost and complexity to the job.

That’s not to say that there are not specialized machines that address this requirement. Combination punching and laser-cutting technology has been around for a long time, and this allows the operator to gain the advantages of flexible shape cutting from the laser and three-dimensional forming from the punch. Still, these machines are generally much more limited in the thickness range they can process than a dedicated laser, and more importantly they lag far behind in processing speed. There are also multi-axis laser-cutting systems that allow for the use of the laser as a true 3D cutting tool, but these systems are intended primarily to cut contoured surfaces and are not very productive when cutting ordinary flat geometry. Flat sheet cutting lasers have also been designed, which incorporate some degree of articulation of the cutting unit, allowing the laser beam to be fired at an angle to the sheet surface to produce a beveled cut. This technology also has its drawbacks and limitations though. Having an articulating cutting unit introduces another possible failure mode for the machine and another maintenance point that needs checking and calibration to stay in good working order. This technology also cannot be used to round off a part edge or create a countersunk hole: Firing the beam through the sheet at angle still means the beam will keep traveling at that angle until its energy disperses.

NEW STRATEGY FOR EDGE TREATMENT

Despite these complications, a newly introduced technology shows it is possible to address this limitation of 2D laser cutting without the introduction of complicated mechanical design or specialized hardware of any kind. By manipulating the laser beam directly, it is possible post-process geometry that has already been cut normal to the surface of the sheet to create a three-dimensional edge profile. This strategy uses capabilities already built into the current generation of solid-state laser-cutting machines, so it becomes possible simply by updating offline programming and machine control software to take advantage of this functionality.

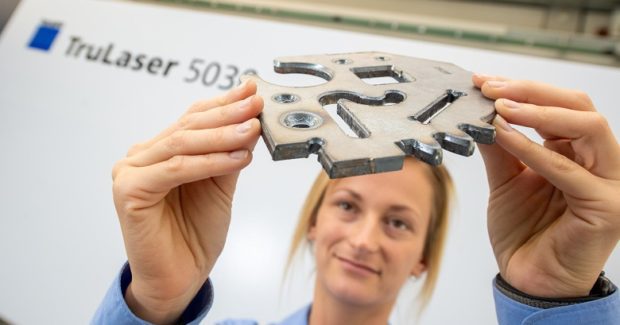

In addition to teaching old machines new tricks, this new strategy for edge treatment using the laser allows for a broader application range than an actual articulating cutting unit would. For example, in addition to beveling cut edges for weld preparation, this strategy can also be used to break sharp edges slightly for safer handling, as well as to create a countersunk hole suitable for receiving a recessed fastener. Because the strategy is entirely software based, adjusting the edge treatment is just a matter of changing parameters: No mechanical setup or change-over is needed.

By bringing the ability to perform edge contouring on flat sheet cutting lasers, this new technology promises to make laser cutting even more flexible as a fabrication tool. And by allowing some secondary part processing (like drilling countersinks) to be pulled back into the cutting machine, this technique can also eliminate some manual production effort and further ratchet down part costs. All in all, it’s a great example of how the laser machine continues to extend its value in manufacturing, and also of how instrumental good software is at realizing the full potential of modern machinery.