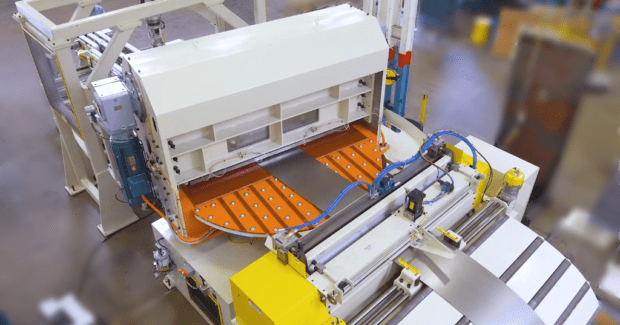

Oscillating Servo Shear Offers Smooth Repeatable Precision with Reduced Maintenance

COE Press Equipment’s (Sterling Heights, MI) Oscillating Servo Shear, as compared to hydraulic shears, is designed to significantly reduce maintenance time and costs as well as provide energy savings and noise reduction.

Posted: November 18, 2021

Additionally, the smooth operation of the servo shear provides the ability to cut both rectangular and trapezoidal blanks with reliable, repeatable precision.

Totally self-contained, the servo shear relies upon a slew ring to support the weight of the shear. This design allows the shear to swivel in back and forth with the help of a second servo axis, attaining different angles for the cut. This shear can manage coil materials from 24-in. to 78-in. wide and up to 0.25-in. thick. When run in continuous mode, the system can reach speeds of up to 240 spm, depending upon the width of the material being run.

Maintenance reduction with a servo system, versus hydraulic systems where components tend to deteriorate due to high pressure and flow rates, occurs because piping, hoses, filters and much of the lubricants are eliminated.

Energy savings are achieved because gravity has little effect on a servo motor in a resting state, requiring very little energy to hold it in a balanced position between cycles. And a reduction in noise is realized because the COE servo shear moves in a smooth, controlled sinusoidal motion, which is very quiet in contrast to the top and bottom slamming of a conventional shear.