Monitoring the Process

Automated measurements of workpieces in machines are progressively more important in today’s manufacturing processes, resulting in shorter production times and fewer interruptions. What’s more, there is more confidence when it comes to the measurement process.

Posted: November 6, 2021

MEASUREMENT & INSPECTION

Innovations in touch probes and portable scanners used for in-process monitoring allow for high-speed scans of larger areas on a variety of surface materials, where thousands of points of data about parts can be gathered in less time. Read on to learn about the new directions and firsts regarding in-process monitoring.

RS-SQUARED AREA SCANNER REPRESENTS NEW DIRECTION FOR PORTABLE MEASURING ARM TECH

Exact Metrology (Cincinnati, OH), a division of In-Place Machining Co., is a comprehensive metrology service provider now offering the RS-SQUARED area scanner. Manufactured by Hexagon Metrology and re-sold by Exact Metrology, this 3D scanner is compatible with all current generation Absolute Arm 7-axis systems. Exact Metrology is ISO AS9100 Certified along with being FFL and ITAR Registered. The RS-SQUARED allows users to perform high-speed scans of simple shapes and surfaces. It is best suited to the scanning of large parts with lower detail requirements, such as automotive parts.

The Absolute Arm 7-axis system delivers tactile probing and laser scanning in a uniquely ergonomic package. RS-SQUARED is a white light scanner that uses the Absolute Arm system to position large square ‘tiles’ of 3D scan data. Up to four data tiles are captured every second, which combined with minimal set-up time, creates a scanning system capable of generating point cloud data in very little time.

Additional features include an extra-large scan ‘tile’ measuring 300-by-300 millimeters. Scans that usually take one hour to scan are digitalized in 10 minutes.

LASER TRACKER SIMPLIFIES ON-SITE MEASUREMENT OF LARGE PARTS AND COMPLEX ASSEMBLIES

Faro Technologies Inc. (Lake Mary, FL) has added two updates to its Vantage Laser Tracker family of products, including the E/S/E6/S6 models. The Vantage Laser Tracker enables on-site measurement of large parts and complex assemblies and reduces inspection times by up to 75 percent, accurately measuring 3D coordinates in real time and comparing that nominal data to CAD schematics. With the updates, the Vantage Laser Tracker family have all been certified to the most rigorous, International Organization for Standardization (ISO) standards. Second, the recently released 6Probe 2.0 not only speeds up measurement, but also has been shown to meet the challenge of accuracies of under 50 microns, allowing the measurement of even the tightest tolerances.

E/S/E6/S6 Laser Trackers are now being certified to ISO 10360-10:2016. The 6Probe is a fully integrated hand-held device for easily probing hidden, hard-to-reach features. The 6DoF probe makes it faster than ever before to perform inspection, alignment, and assembly tasks. The 6Probe features a retroreflector to measure the position of the probe, a series of LED lights that are analyzed to determine the probe orientation and a calibrated probe tip. With common orientation, a 2.3m scale bar can typically be measured to less than 46-micron error at 2.5m, and 73 micron at 10m.

With a 6DoF probe users can measure “hidden” points up to 15 meters away without the need to relocate the Laser Tracker, as well as inspect tight spots.

NEW HIGH-PRECISION TOUCH PROBE FOR GRINDERS/LATHES

HEIDENHAIN Corp.’s (Schaumburg, IL, and San Jose, CA) TS 750 high-precision touch probe is available for in-process workpiece measurement in grinding machines and lathes. The extremely durable new probe offers the ability to state the reproducibility of its jobs at increased probing speeds better than its competitors. And the low probing force inherent in the TS 750 is an important benefit when working with soft or delicate workpieces.

The TS 750 operates with high-precision pressure sensors, with force analysis for generating the trigger pulse. The forces that arise during probing are processed electronically. This method delivers extremely homogeneous, 360° probing accuracy. It offers high probing speed of up to 1 m/min and does not require a minimum speed.

Also, due to its very low probing forces of approximately 1.5 N (axial) and 0.2 N (radial), the TS 750 can attain high probing accuracy (±1 µm) and repeatability with almost no effect on the measured object. Only on further deflection do the forces of the springs take effect until the machine stops.

Delivering reliable measurements after prolonged use — even after five million probing cycles — the TS 750 touch probe is still highly accurate: with a probing repeatability of down to 2 σ ≤ 0.25 µm at its high probing speed, which is highly unusual in the industry.

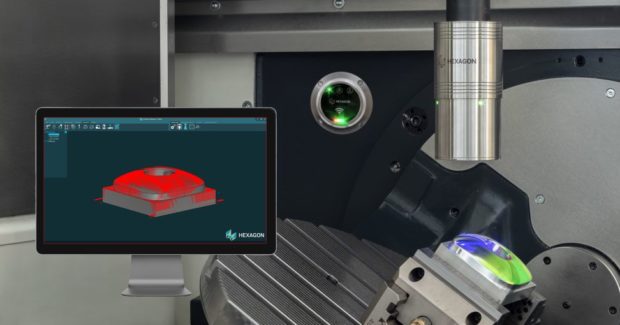

WORLD’S FIRST WIRELESS LASER SCANNER FOR MEASURING PARTS ON CNC MACHINES

Hexagon’s Manufacturing Intelligence (North Kingstown, R.I.) business has launched a wireless laser scanner with metrological precision, specifically designed for use in CNC machine tools. The m&h LS-R-4.8 radio laser scanner can detect around 40,000 measuring points per second — compared to the current standard, in which individual points are recorded with conventional measuring probes — and transmits the data safely via radio to the receiver, which enables the operator to automatically change sensors without manual intervention. The acquisition of 40,000 measuring points per second provides information about the entire part and not only about selected individual points.

Measuring in the machine tool, whether for workpiece control, temperature detection or tool measurement, is a valuable source of information in the machining process. With this data, workpieces can be checked before or between processing steps. The wireless scanner eliminates bottlenecks by taking inline measurements for process improvements away from CMM machines and enables fast measurements in the machine tool.

The wireless scanner uses laser triangulation to achieve a high level of speed and accuracy. The laser beam is projected onto the component, its reflection then passes through a lens and is detected by an image sensor. From this information, the measuring points are then determined.

Special modular software presents the data in an easy-to-understand format so that machine operators or quality teams can quickly identify problems and correctly align the part for post-processing while it is still in the clamping process. The wealth of data presents operators with new possibilities, including creating color charts that are graphically superimposed on the CAD model to detect deviations.

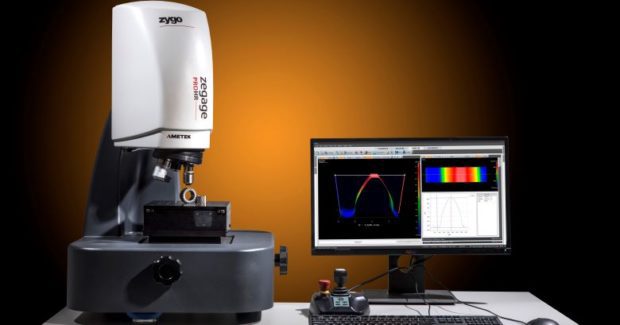

ZEGAGE™ PRO AND PRO HR SYSTEMS FOR IN-PROCESS METROLOGY

Optical metrology leader Zygo Corp. (Middlefield, CT), a business unit of Ametek, Inc., provides 3D optical profilers across a variety of industry sectors. The profilers are used to measure height variations, such as surface roughness on surfaces, with exceptional precision using light to probe the surface and avoid any direct contact. The ZeGage™ Pro uses Coherence Scanning Interferometry (CSI) as its core measurement technology, which today is a well-established method of obtaining accurate surface measurements.

The latest generation base, the ZeGage Pro model, delivers surface mapping at the nanometer scale, meeting the needs for most industrial surfaces. For smoother samples, with a much finer surface finish, the ZeGage™ Pro HR offers more than 20X higher precision with 0.15 nm vertical precision.

With the ZeGage Pro and Pro HR systems, proprietary non-contact measurement technology is enhanced with SureScan™ technology for low sensitivity to vibration and easy placement anywhere within a production facility. Quantitative surface metrology with nanometer-level precision provides superior gage capability. These are now paired with ZYGO’s exclusive Part Finder and Smart Setup tools.

All ZeGage Pro and Pro HR systems run the interactive control software Mx™, which offers complete system control and data analysis and provides comprehensive tools for surface data visualization, analysis and reporting such as interactive 3D maps, quantitative topography data, intuitive navigation, and built-in SPC with statistics, control charting, and pass/fail limits.

The products feature a 1.9-million-pixel image sensor that provides fast areal measurements in seconds, for excellent surface detail and visualization, and ISO 25178-compliant results.