Hypertherm’s New Robotmaster Update Allows for Faster Programming of Robots

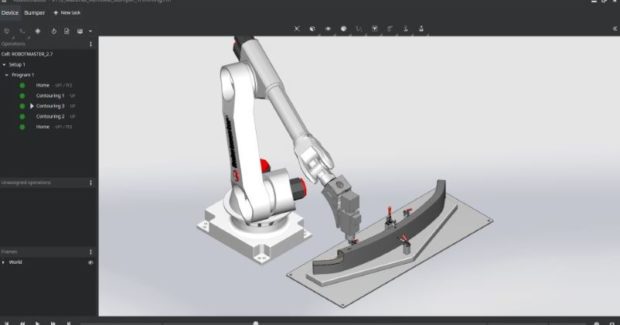

Hypertherm Inc. (Hanover, NH) has announced an update to its Robotmaster® software, which is used for offline programming of robots.

Posted: October 14, 2021

The version 7.5 update focuses on accelerating and simplifying the programming process and includes new features for a variety of robotic applications.

Hypertherm said the software’s key highlights include:

- New material removal simulation capabilities so users can visually see what the material removal process will look like. This can help users forecast whether a collision between the robotic arm and stock material could occur in real life.

- Improvements to the overall user experience (UX) and user interface (UI) for easier and faster programming. Users will experience an improved tab system menu design, a cleaner interface, and other improvements for an overall 50 percent reduction in programming time.

- Streamlined programming using two new modes: Operation-focused and Orientation helper. Operation-focused consolidates the tools and workflows needed for an error-free program onto one window. Orientation helper combines axis configuration and optimized automatic path planning, so it can provide live feedback on the feasibility of a planned operation, making it well-suited for task experts with no robotics experience.

- Enhanced CAM functionality to manage and store operation parameters in an optimized manner, resulting in a smoother programming experience.

- Formalized and enhanced support for macros to manage and validate robot behavior outside of the trajectory scope. A new feature called Macro manager ensures an error-free and collision-free path between operations and the executed external macro.

- New simplified processor framework allows users to make updates with minimal training and no coding experience.

Hypertherm manufactures industrial cutting systems and software.

Subscribe to learn the latest in manufacturing.

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

More fabricators are using larger-diameter grinding wheels and flap discs for their...