Clear the Air

Harmful particulates in job shops pose risks to both your workers and your facility. Fortunately, there are versatile, durable, modular, more compact and customizable fume and dust collectors that improve indoor air quality by creating a safe environment and protecting your machinery and facility from fires, for example.

Posted: October 10, 2021

ENVIRONMENTAL & SAFETY

How a Metal Fabricator Improved Air Quality and Reduced Fire Risk

Air quality has an impact beyond employee health and well-being — particulates can create hazardous conditions and increase the risk of property damage from fires and dust build-up on equipment. One manufacturing company implemented a new IVEC Systems (New Berlin, WI) weld fume collection system to not only improve working conditions for its employees, but to increase the overall efficiency and safety of their plant.

Background

A Midwest metal fabricator’s existing exhaust system used fans that were ducted to individual robot and seam welders, and these fans were unable to generate enough exhaust air and dust velocity to effectively remove particulates from the air. Dust that settled in the ducts resulted in multiple minor fires within the ductwork.

The previous ducted system required manual cleaning of ductwork, motors and blowers. In addition, the system exhausted the collected air outside the facility, requiring “make-up” air to eliminate potential negative air pressure in the building. This drove up operating costs, especially during the winter when already heated exhaust air was lost, and new make-up air had to be heated.

Weighing the Options

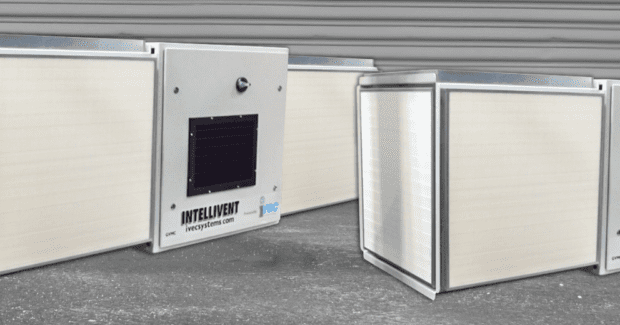

The company evaluated an ambient air filtration system utilizing a unique filtration unit with energy optimizing controls that would create the necessary air exchange rates to effectively remove particulates from the air and promised significant energy reduction and cost savings compared to other options.

The ambient collection units could also be monitored remotely through automation and control software, allowing maintenance personnel to track filter status, monitor system faults, and turn the system off from anywhere in the world. Administrators could schedule unit operation based on production schedules, so units can automatically turn on and off as required to conserve energy.

The non-ducted ambient collection system has a smaller footprint that opened additional workspace in the facility and the new system cleans all the air in the building, not just in specific areas where welding is taking place. The external exhaust blowers and ductwork have been eliminated and the new system runs on filter pressure, which reduces the amount of energy required to operate the system.

Results

Post-installation testing revealed an 82 percent reduction in weld fume and employees immediately noticed an improvement in air quality in the manufacturing plant. The new system significantly reduced the risk of fires and created a cleaner and more comfortable work environment.

RoboVent Releases Most Versatile Dust Collector in the Industry

RoboVent (Sterling Heights, MI) has launched its most powerful and versatile industrial dust collector yet: the RoboVent Senturion. With an innovative modular design and advanced filter technology, Senturion has the smallest footprint per CFM in the industry. The Senturion line moves RoboVent beyond its traditional focus on metalworking and welding with a unit optimized for bulk and powder and other heavy-duty industrial applications.

RoboVent is part of the Rensa Filtration family of air filtration companies. Senturion is RoboVent’s new flagship industrial dust collector. Thanks to its modular components, it can be adapted to any application, including food processing, pharmaceutical, surface prep, abrasive blasting, surface mining, recycling, plastic production and other challenging environments. In addition to its machines, RoboVent provides turnkey service for dust collection and industrial ventilation design, engineering, installation and service.

Senturion is built using 2- and 4-cartridge frames, which can be put together in different configurations. This approach allows the dust collector to be sized precisely for the application, from an individual welding booth to an entire facility. Alysha Yinger, director of engineering, said: “With our modular approach, it can be sized and customized for just about any application, including heavy powder, abrasive dust, combustible dust, ultra-fine particulates, and even gases, vapors and odors.”

Some of Senturion’s features include:

- Tough cabinet construction with 7- and 11-gauge steel. The cabinet is powder-coated inside and out for longevity and backed by a 15-year workmanship warranty.

- RoboVent PleatLock® filters maximize the available filter media in the cartridge.

- An advanced pulsing system that gets more dust off the filters to extend filter life and reduce maintenance requirements.

- Advanced fire and explosion protection options that meet OSHA standards and NFPA guidelines for control of flammable or combustible dust.