Seeing Double: How Smart Factories Use Digital Twins

Implementing digital twins in your shop allows you to understand what is happening in your machines now and in the future. The data allows you to extract meaning.

Posted: September 16, 2021

COVER STORY

By Rachel Duran

Manufacturers are continuously barraged with messages about how digital transformation will make their machines smarter, reducing downtime and the production of bad quality parts. The global pandemic exposed weaknesses in shops, particularly in the supply chain, accelerating the need to digitize.

Your peers are paying heed to the messages and incorporating Industry 4.0 technologies, including digital twins. When responding to a recent Industry Week survey, which inquired “which technologies will drive investment at your organization over the next 12 months,” leading the way at 51 percent was data analytics followed by 39 percent for robotics/automation.

Technologies, such as digital twins (at the basic level, a 3D model of the physical hardware on the factory floor), don’t have to solve all your production challenges overnight. However, shops can begin networking machines within a couple of days of making the decision to innovate. You don’t need to buy more machines; you just need to optimize the ones you have. The data from digital twins provides a deep understanding of your capacity and how you can better use that capacity and increase throughput. The data allows operators to efficiently operate more pieces of equipment. “It is actually the data from your operations that represents the digital twin,” said Bill Bither, co-founder and CEO of MachineMetrics.

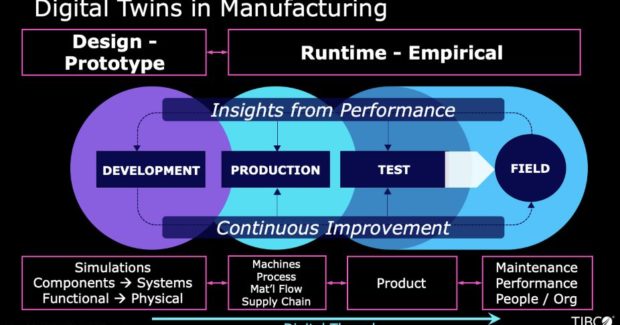

A digital twin is a virtual high-definition model or series of models of a real thing, such as a machine instrumented with sensors on it, said Mike Alperin, principal manufacturing industry consultant on TIBCO Software Inc.’s data sciences team. “The virtual machine is connected to the real machine via the sensors and the Internet of Things,” he said.

Today’s AI-based digital twin models can produce an accurate real-time representation of both the physical state and behavior of a particular machine. “The software model can provide valuable insights into internal states that would not normally be observable,” Alperin said. They can also predict what a piece of machinery will do in the future.

By mapping out what is taking place in the machines, your shop has improved visibility, allowing you to manage expectations. Operators no longer need to “listen” to estimate when a machine tool will go bad. The data shows you when a tool is ready to break down, and will shut a machine down, preventing the production of bad parts and minimizing scrap.

Monumental Advantage

In an example from BC Machining LLC, a small contracting shop in Brasstown, N.C., the operators decided it was more cost effective to run a machine tool to failure, even though a preventative condition was set up so they could replace the tool after a certain amount of uses; however, it was random when the tool would break. The company was running tourniquet handles at a very high volume. By using predictive analytics, whereby accessing data in high frequency, MachineMetrics worked with the shop to normalize the data into its basic core components.

With the cutting tool, “we could understand the friction, the load, the speed, the feeds, and with that we were actually able to determine the pattern that led up to this failure,” Bither said. “We implemented a solution that would tell the machine to stop and notify the operator so that instead of the operator having to listen, they would be notified on their phone and the machine would stop so it wouldn’t produce bad quality parts.” From there, the operators replace the tool and hit start again, eliminating the need to throw out scrap.

BC Machining was able to network machines with an edge platform device from MachineMetrics within a couple of days, without anyone from the outside coming into the plant. “Since using the MachineMetrics predictive tool breakage technology, almost all of our waste has been eliminated,” said Bob Merrill, BC Machining’s owner. “We’ve calculated the savings at our Swiss turn machines to be about $72,000 annually…it’s been monumental to say the least.”

“It really is a journey,” Bither said. “You typically start with the basics and move your way to advanced [uses] and it is all around this data that we are capturing from the machine.”

Alperin suggested machine shops look at problems they need to solve as it relates to digitizing the factory floor. For example, are you struggling with having the correct material available when you need it? Is there a product yield issue or quality issue? When addressing the challenge first you can work your way back from the problem you want to solve to determine what type of system to put together.

In what Alperin called an advanced automotive use case for digital twins, and where some of the insights can work their way back to the design of new automobile models, the Mercedes-AMG Petronas Formula One racing team uses many digital twins to model performance as a function of factors such as track conditions, the weather, the car’s suspension and balance, the tires, how much fuel is in the car and so on. The team runs the digital twins before the race to optimize the car for race day. “There are hundreds of sensors on the car and they are able to optimize the setup of the vehicle beforehand and even tweak it in real time during the race,” Alperin said.

The Case for Getting Started

Access to data improves visibility inside the machines, where dashboards allow operators to see what is expected of them regarding output, instead of having to guess. Notifications also alert operators to shift over to a machine that is waiting for new material, and then return to fixing another machine. “Those are the types of workloads you can build into your system and really help that operator be more efficient,” Bither said.

More advanced examples can be applied to the soon to retire workforce and the transfer of knowledge to the next generation of workers. Bither said there is a bit of an art to manufacturing and operators have a deep tribal knowledge of what a machine sounds like when it is running well and what it sounds like when there is a problem, such as a tool or bearing wearing out. “Having that deep understanding of the physics of a machine is going to help take that tribal knowledge and transfer it to this new generation of workers,” Bither said. “So, if you are going to tie that digital twin to that workforce, that is how I would look at it.”

Bither said it is an exciting time for the digital factory. “It’s more than just to improve your bottom line — it is a global trend. And if you don’t invest in this you will fall behind.”

And you can start small. “Users should not have the perception that you really have to invest a lot and go in for a full-scale digital twin,” said Vivek Furtado, head of machine tool digitalization for Siemens. “There are several steps you can take to get there without having to invest a lot of capital.”

Furtado said the digital twin itself brings many use cases including process optimization, validating a part program, training and simple job preparation. “This can be done, and in fact is being done today, also without a complete digital twin,” he said. “My message? Just get started.

“We have a very economical product called SinuTrain, for example, that also has integrated simulation in it where you can upload part of your machine capabilities into that model,” Furtado continued. This allows shops to get started on the road to digitalization, saving valuable resources by training new people on a new machine, which prevents machine down time. (Users can get started by downloading a free copy of SinuTrain. To view the complete Q&A with Furtado and a discussion on SINUMERIK ONE digital first strategy, which includes Create MyVirtual Machine, visit www.fabricatingandmetalworking.com.)

By embracing digitization for the factory floor, such as establishing digital twins, your shop will not only manage expectations better, but the agility you gain will create growth and expansion opportunities. Not only that, by optimizing your process, you will build better parts.